44 Elements of Card Design

Printing Design

Printing design includes color and monochrome printing, bar code printing, non-printing areas,

and card layout.

Color Printing

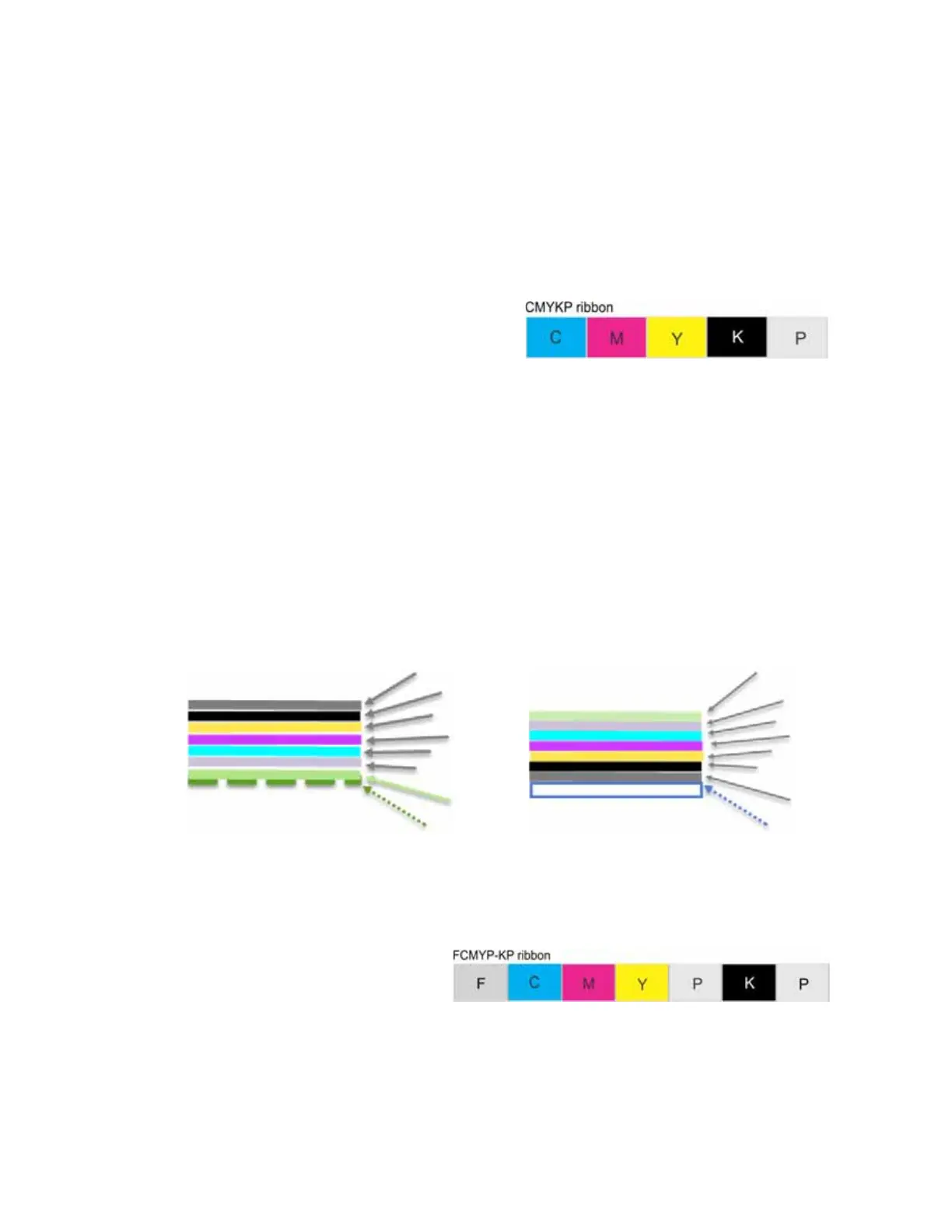

The retransfer printing process uses two types of

supply: a color pigment ink ribbon and a

retransfer film. The color ink ribbon typically

contains the following panels, C (cyan), M

(magenta), Y (yellow), K (black), and P (primer). Other ribbon types also may have an ultraviolet

(F) panel or an inhibitor (I) panel.

The printer prints separate layers of cyan, magenta, yellow, black, and primer on a transparent

retransfer material. Heat from the printhead causes the ink pigment to release from the ribbon

and adhere to the retransfer material. The printed images are then transferred to the card using a

heated roller.

The layers are applied to the card in the reverse order that they were applied to the retransfer

film. The primer, which is applied last to the retransfer film, is applied first to the card and allows

the image layers to bond to the card surface. The retransfer film consists of a carrier material and

a film coating. The coating is applied last to the card and acts as a protective layer for the printing.

You can select to apply a second layer of the retransfer film coating for added durability.

If the printer includes the optional laminator, the patch overlay applied by the laminators

provides additional protection against wear.

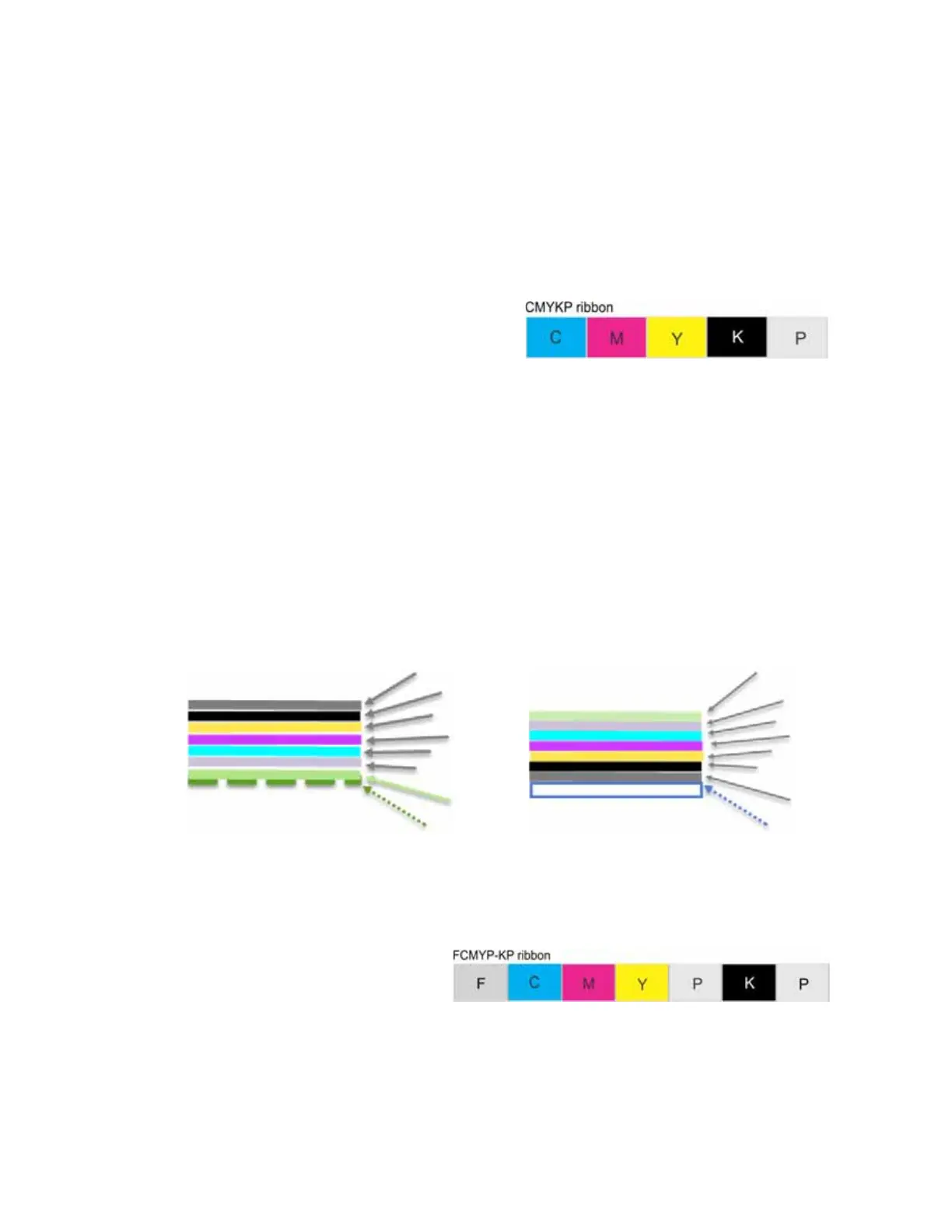

Color ink ribbons with an ultraviolet

F (fluorescent) panel, FCMYP-KP, also

are available. The UV printing is

undetectable under normal lighting

and provides an additional form of

security.

Primer

K

Y

M

C

UV

Film Coating

Retransfer Film

Carrier Material

Print Order on Retransfer Film

Order on Card

Film Coating

UV

C

M

Y

K

Primer

Card

{

{

Ribbon

Retransfer

Film

Loading...

Loading...