Instructions for use D-Vapor/D-Vapor 3000 95

Service

Inspection

Regular inspections must be carried out and logged

in accordance with the following requirements and

at the stated intervals.

The inspections and safety checks are identical for

D-Vapor and D-Vapor 3000.

Safety checks

The safety checks do not replace the manufacturer-

specified maintenance and its preventive

replacement of wear parts.

1 Check accompanying documents:

– Associated instructions for use for the

medical device present.

2 Check the medical device to see that the ready-

to-use product is complete in accordance with

the instructions for use.

3 Check the equipment combination for perfect

condition:

– Markings are complete and legible

– No damage

4 Check function and safety:

– Checking operational readiness (see

chapter "Operation" on page 54).

– Check of electrical safety according to

IEC 62353 (device leakage current <50

A)

or IEC 60601 (normal condition NC*

<50

A,SFC** <100 A)

– Check emergency power operation

Battery charged for 1 hour; the vaporizer

must dose for 5 minutes in battery operation

at a flow rate of 4 L/min and control dial

position 6 Vol%

– Check of leak tightness with vaporizer

switched off and control dial positions 0 and

18 Vol%

Test pressure: 350 hPa (357 cmH2O),

Test value: Leakage rate <3 mL/min relative

to an ambient pressure of 1013 hPa

(14.69 psi)

– Check of pneumatic resistance in control

dial position 0 and 2 Vol%

carrier gas: Air, flow: 10.0 L/min.

Checks Interval Personnel responsible

Inspection and safety checks Every 12 months Service personnel

WARNING

Risk of patient injury

Perform safety checks at the indicated inter-

vals. Otherwise, the correct functioning of the

medical device may be compromised.

* NC: Normal Condition

** SFC: Single Fault Condition

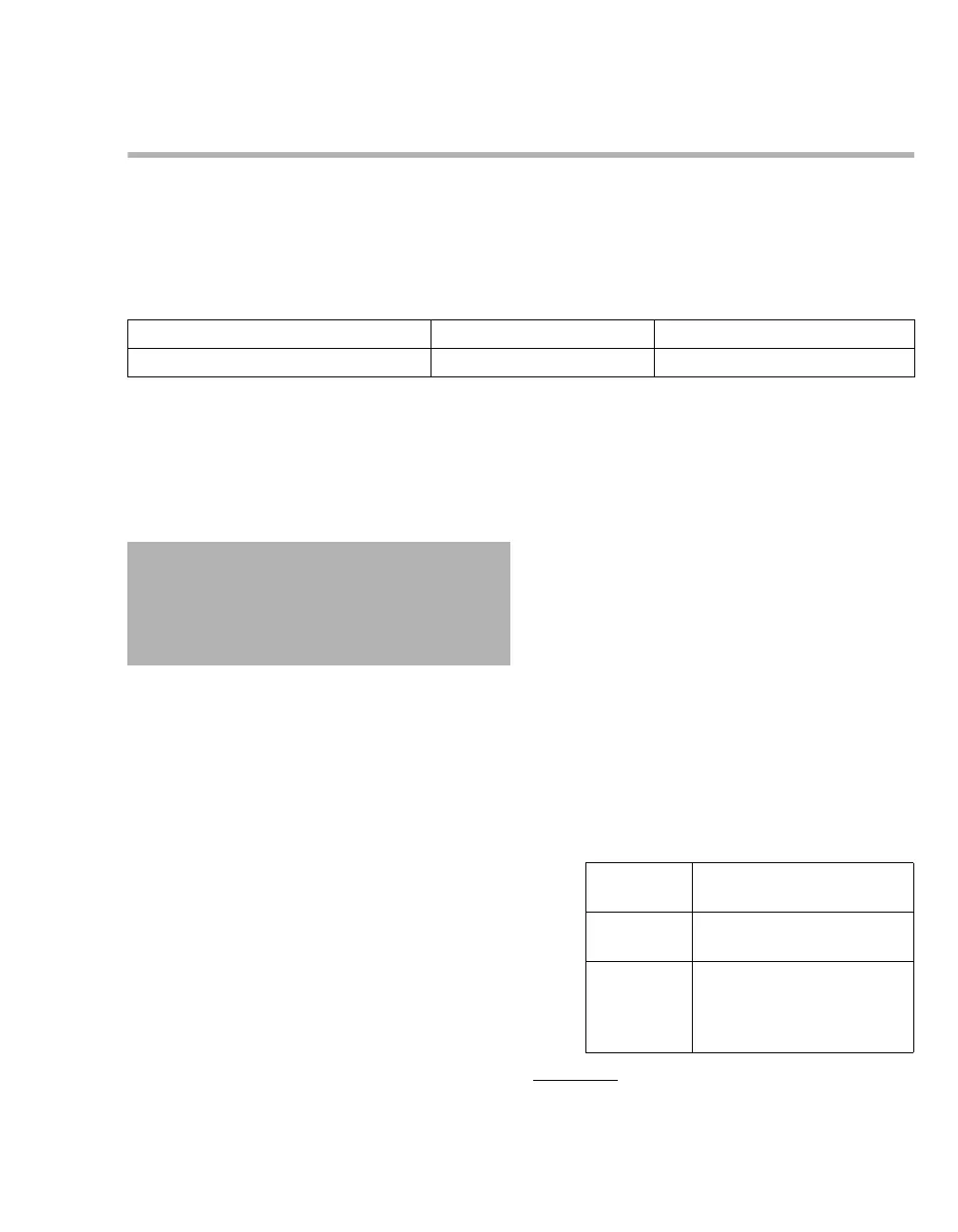

Control dial

position

Test value

0 10 to 28 hPa

(10.2 to 28.6 cmH

2O)

2 Pressure increase relative

to control dial position 0 by

53 to 79 hPa

(54 to 80.1 cmH

2O)

Loading...

Loading...