Transducer Mounting Congurations

V-Mount and W-Mount Configurations

Apply the Couplant

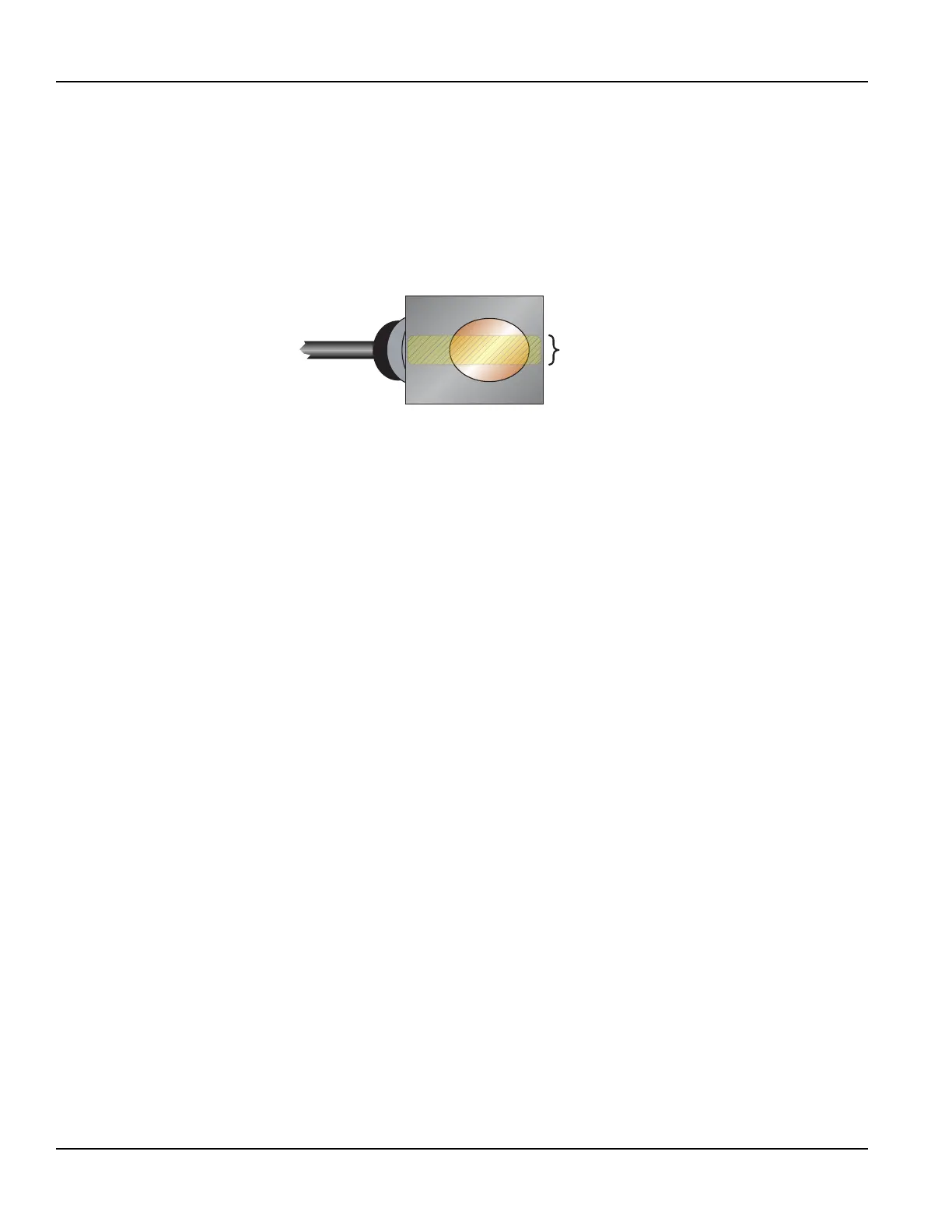

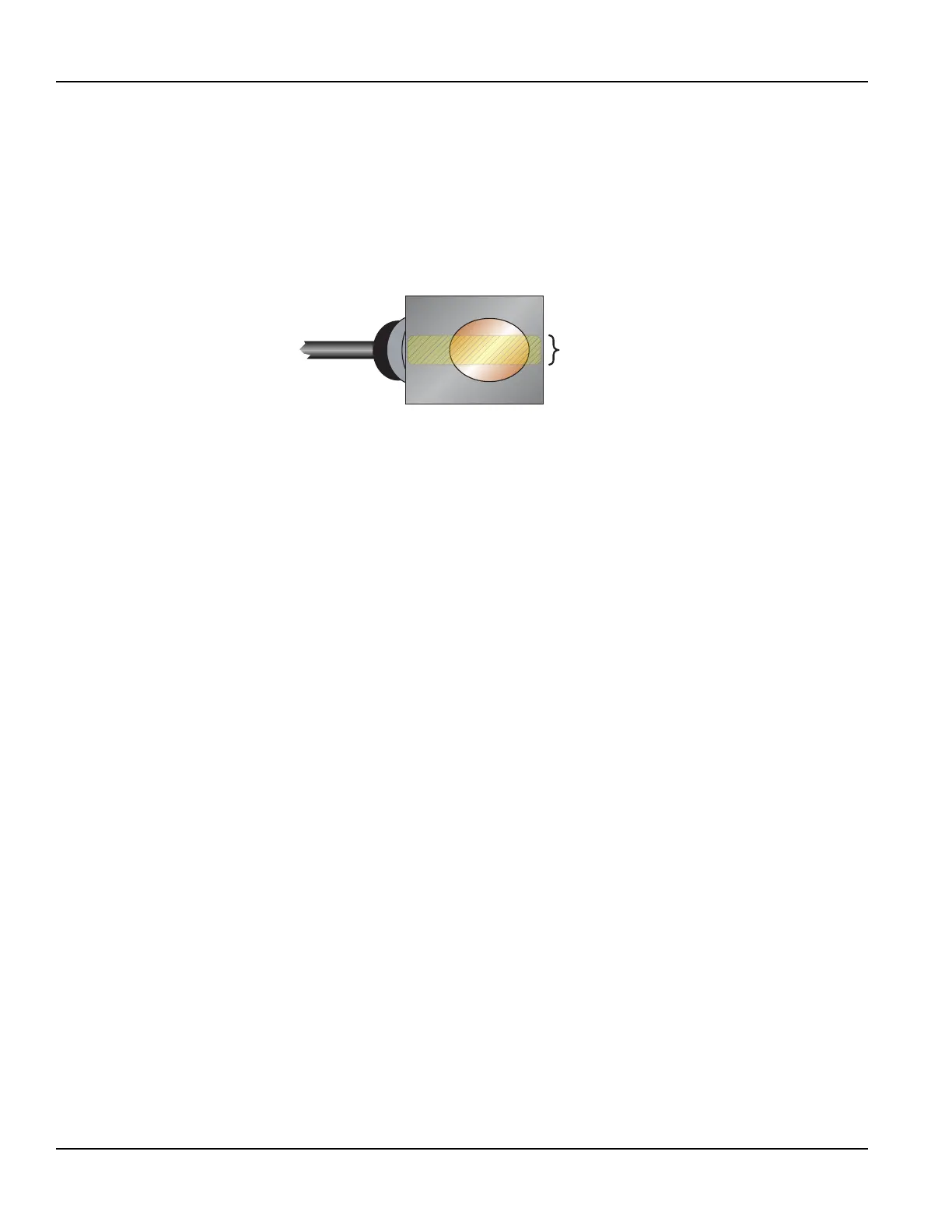

For DTTR, DTTN, DTTL and DTTH transducers, place a single bead of couplant, approximately 1/2 inch (12 mm) thick, on the

flat face of the transducer. See Figure 12. Couplant is provided with the transducers. Generally, a silicone-based grease is used

as an acoustic couplant, but any good quality grease-like substance that is rated to not ow at the operating temperature

of the pipe is acceptable. For pipe surface temperature over 130° F (55° C), use high temperature acoustic coupant such as

Krytox® LVP (P.N. D002-2011-012). For installations that must be silicone free, use Molykote G-N couplant (P.N. D002-2011-009).

½ in.

(12 mm)

Figure 11: Application of couplant

Position and Secure the Transducer

1. Place the upstream transducer in position on the pipe. Slide the strap into the arched groove on the end of the transducer.

Wrap the strap around the pipe. Slide the free end of the strap into the end clip of the strap with the screw at 90 degrees

to the strap. Pull the strap through until it loosely ts around the pipe. Rotate the screw so it is parallel to the strap and

tighten the screw slightly to help hold the transducer onto the pipe. Verify that the transducer is true to the pipe and

adjust as necessary. Tighten the strap screw to secure the transducer to the pipe.

2. Place the downstream transducer on the pipe at the calculated transducer spacing. See Figure 13 on page21. Apply rm

hand pressure. If signal strength is greater than ve, secure the transducer at this location. If the signal strength is not ve

or greater, using rm hand pressure slowly move the transducer both towards and away from the upstream transducer

while observing signal strength.

Signal strength can be displayed on the transmitter’s display or on the main data screen in the UltraLink software utility.

See “Parameter Configuration Using UltraLink Software” on page48. Clamp the transducer at the position where the

highest signal strength is observed. The factory default signal strength setting is ve. However, there are many application-

specic conditions that may prevent the signal strength from attaining this level. Signal levels less than ve will probably

not be acceptable for reliable readings.

OTE:N Signal strength readings update only every few second. Move the transducer 1/8 inch then wait to see if the signal is

increasing or decreasing. Repeat until the highest level is achieved.

3. If, after adjusting the transducers, the signal strength does not rise to above ve, use an alternate transducer mounting

conguration. If the mounting conguration was W-Mount, re-congure the transmitter for V-Mount, move the

downstream transducer to the new spacing distance and repeat the procedure “Mount the Transducer” on page19.

Transducer Installation

Page 20 May 2016TTM-UM-00136-EN-06

Loading...

Loading...