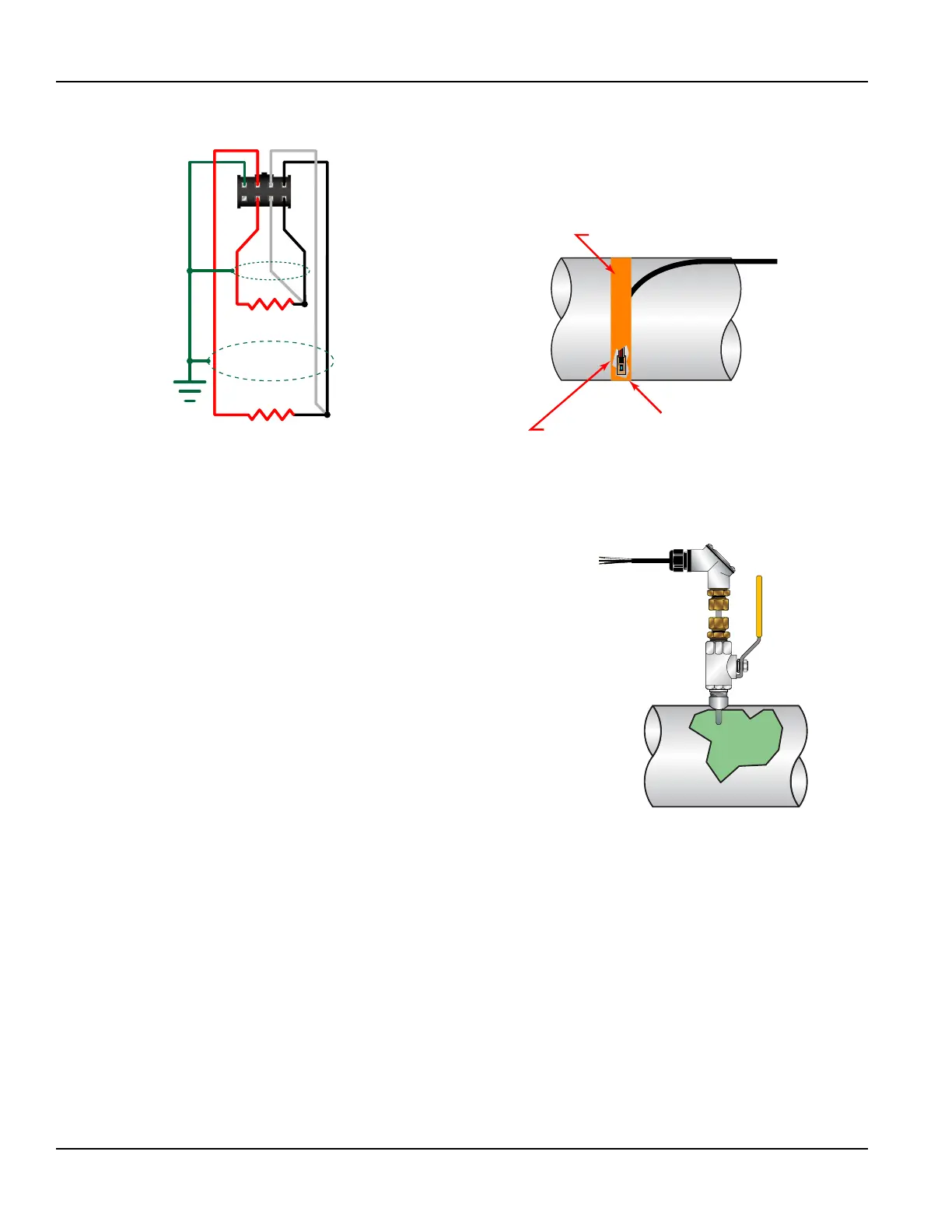

1000 Ω

1000 Ω

SUPPLY LINE

RTD #1

RETURN LINE

RTD #2

BACK OF

CONNECTOR

Figure 34: RTD schematic

MINCO

Clean RTD Mounting

Area to Bare Metal Surface

Heat Sink

Compound

Heat Tape

Figure 35: Surface mount RTD installation

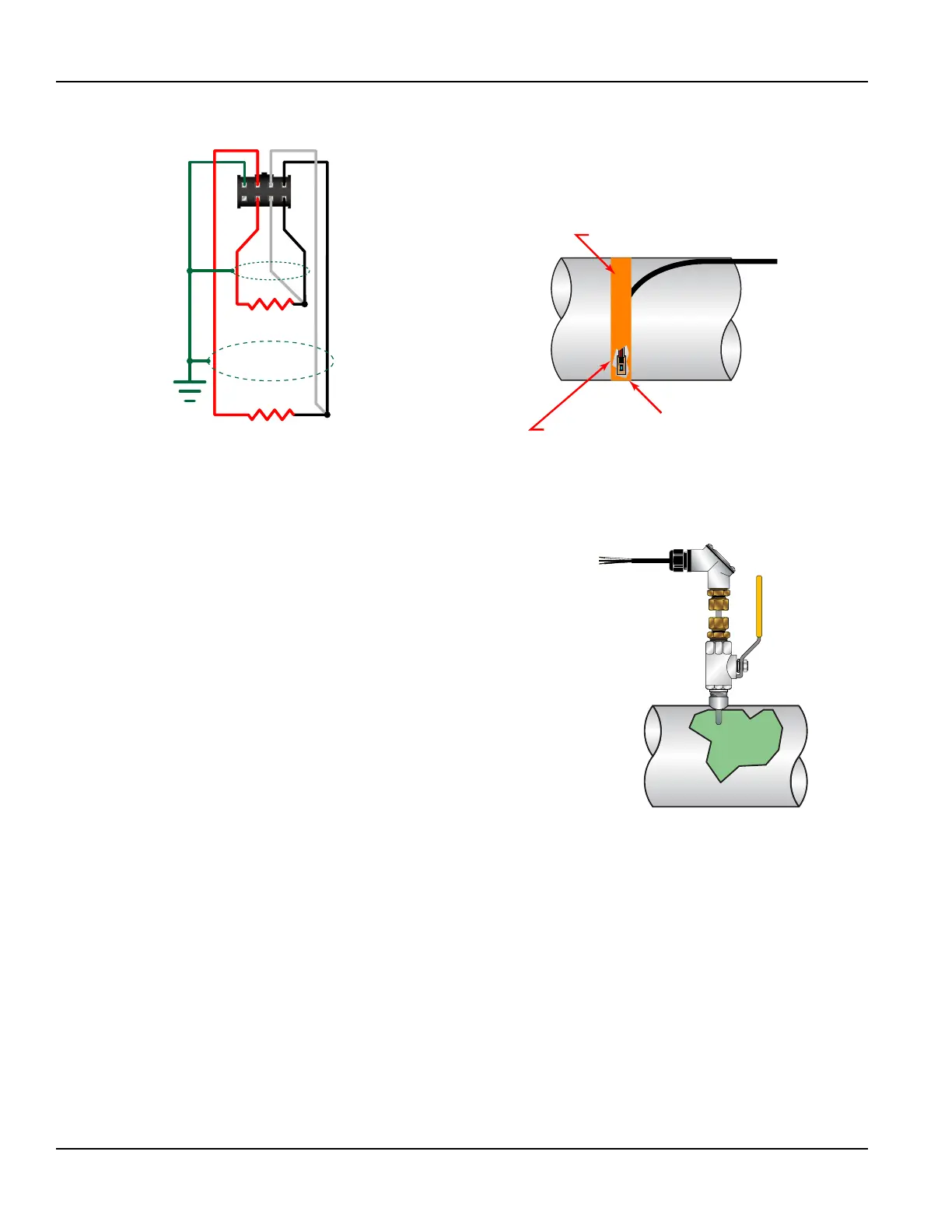

Installing Insertion (Wetted) RTDs

Insertion RTDs are typically installed through 1/4 inch (6 mm) compression

fittings and isolation ball valves.

1. Insert the RTD suciently into the ow stream such that a minimum of

1/4 inch (6 mm) of the probe tip extends into the pipe diameter.

RTDs should be mounted within ±45 degrees of the side of a horizontal

pipe. On vertical pipes, the orientation is not critical.

2. Route the RTD cables back to the transmitter and secure the cable so it

will not be pulled on or abraded inadvertently.

If the cables are not long enough to reach the transmitter, route the

cables to an electrical junction box and add cable from that point. Use

three-wire shielded cable, such as Belden® 9939 or equal.

OTE:N Adding cable adds to the resistance the transmitter reads and may

have an effect on absolute accuracy. If cable is added, add the

same length to both RTDs to minimize errors due to changes in

cable resistance.

Figure 36: Insertion style RTD installation

Wiring RTDs to the Transmitter

After the RTDs have been mounted to the pipe:

1. Route the cable back to the transmitter through the middle hole in the enclosure.

2. Insert the RTD connector into the mating connector on the circuit board. Be sure that the alignment tab on the RTD cable

is up.

Heat Flow for Energy Model Only

Page 32 May 2016TTM-UM-00136-EN-06

Loading...

Loading...