Service Menu (SER)

The SER MENU menu allows access to transmitter setup values that may need revision due to application-specific conditions

and information valuable in troubleshooting.

Parameter Meaning Description

SSPD MPS

Liquid sound

speed in meters

per second,

reported by the

firmware

The transmitter performs an actual speed-of-sound calculation for the liquid it is measuring. The calculation varies with

temperature, pressure and fluid composition.

The transmitter compensates for fluid sound speeds that vary within a window of ± 10% of the liquid specified in the BSC

MENU. If this range is exceeded, error code 0011 appears on the display and you must correct the sound speed entry.

The value indicated in SSPD measurement should be within 10% of the value specified in the BSC MENU item FLUID SS. (The

SSPD value itself cannot be edited.) If the actual measured value is significantly different (> ± 10%) than the BSC MENU’s

FLUID SS value, there may be a problem with the instrument setup. An entry such as FL TYPE, PIPE OD or PIPE WT may be in

error, the pipe may not be round or the transducer spacing is not correct.

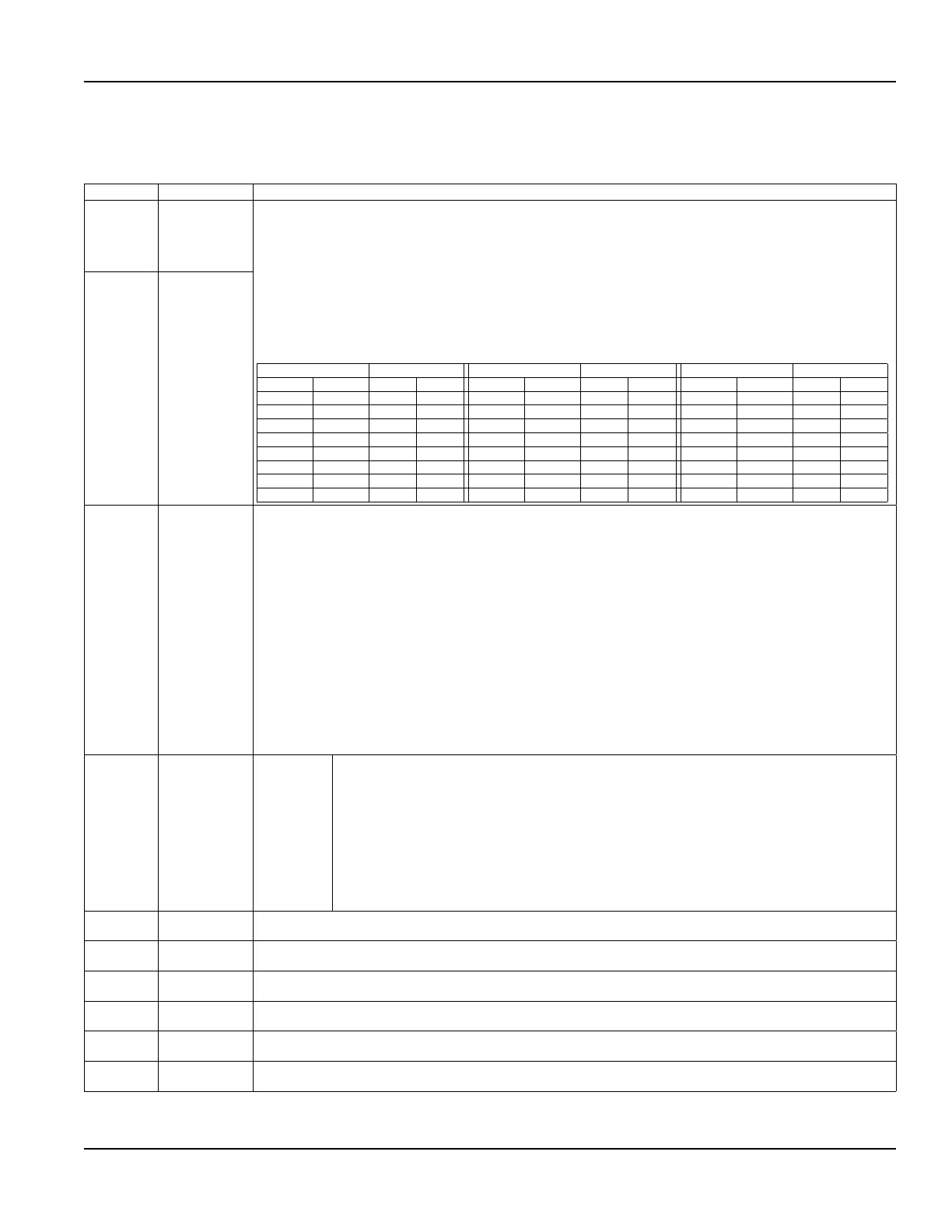

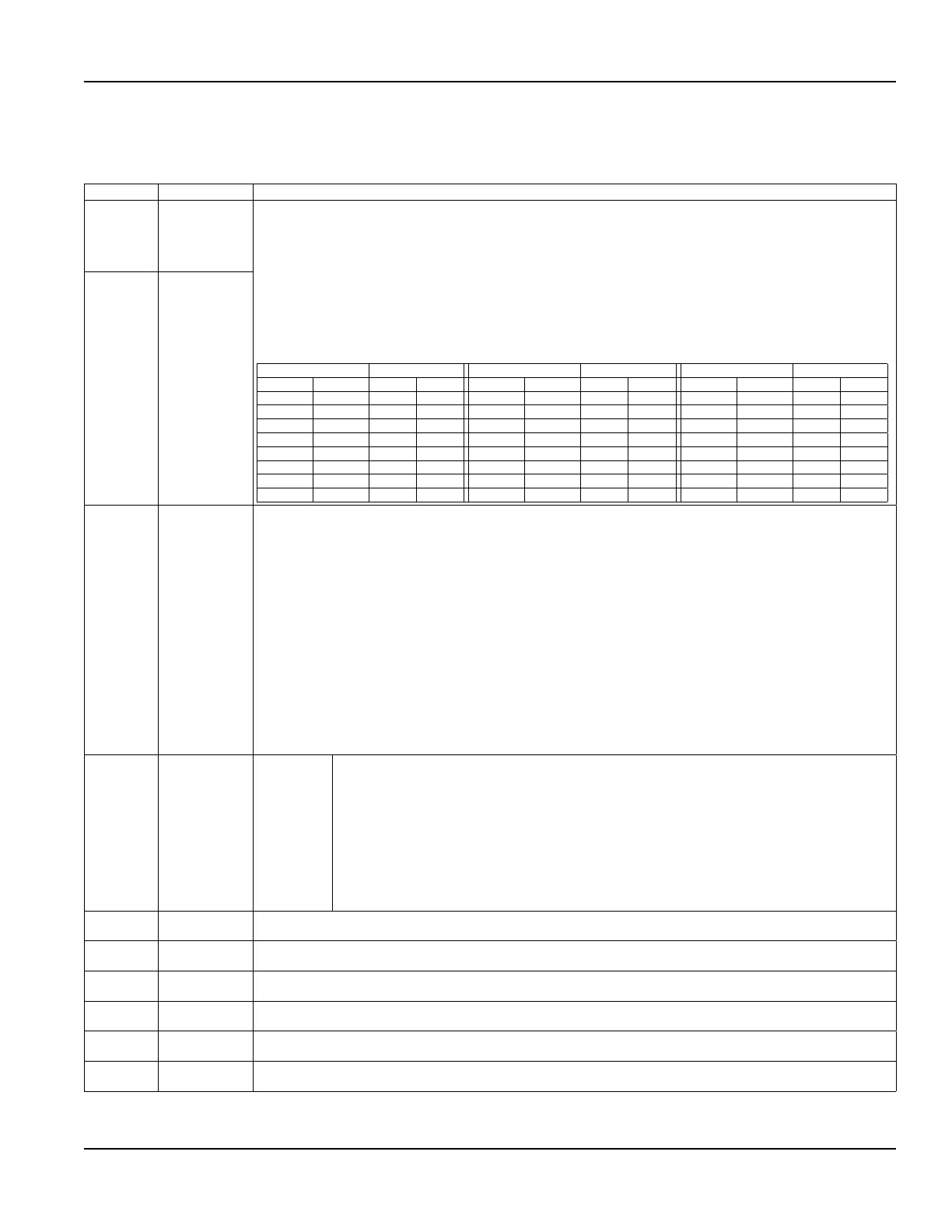

The following table lists sound speed values for water at varying temperatures. If the transmitter is measuring sound speed

within 2% of the table values, then the installation and setup of the instrument is correct.

Temperature Velocity Temperature Velocity Temperature Velocity

° C ° F mps fps ° C ° F mps fps ° C ° F mps fps

0 32 1402 4600 80 176 1554 5098 160 320 1440 4724

10 50 1447 4747 90 194 1550 5085 170 338 1412 4633

20 68 1482 4862 100 212 1543 5062 180 356 1390 4560

30 86 1509 4951 110 230 1532 5026 190 374 1360 4462

40 104 1529 5016 120 248 1519 4984 200 392 1333 4373

50 122 1543 5062 130 266 1503 4931 220 428 1268 4160

60 140 1551 5089 140 284 1485 4872 240 464 1192 3911

70 158 1555 5102 150 302 1466 4810 260 500 1110 3642

SSPD FPS

Liquid sound

speed in feet per

second

SIG STR

Signal strength

reported by the

firmware

The SIG STR value is a relative indication of the amount of ultrasound making it from the transmitting transducer to

the receiving transducer. The signal strength is a blending of esoteric transit time measurements distilled into a usable

overall reference.

The measurement of signal strength assists service personnel in troubleshooting the transmitter system. In general, expect

the signal strength readings to be greater than five on a full pipe with the transducers properly mounted. Signal strength

readings that are less than five indicate a need to choose an alternative mounting method for the transducers or that an

improper pipe size has been entered.

Signal strength below the low signal cutoff SIG C-OF value will generate a 0010 error (Low Signal Strength) and require

either a change in the SIG C-OF value or transducer mounting changes.

OTE:N If the transmitter is configured to display totalizer values, the display will alternate between error 0010 and the

totalizer value.

Signal strength readings in excess of 98 may indicate that a mounting method with a longer path length may be required.

For example, if transducers mounted on a 3 inch PVC pipe in V-Mount cause the measured signal strength value to exceed

98, change the mounting method to W-Mount for greater stability in readings.

Because signal strength is not an absolute indication of how well a transmitter is functioning, there is no real advantage to

a signal strength of 50 over a signal strength of 10.

SIG COF

Low signal cutoff

value

Options:

0.0…100.0

The SIG C-OF is used to drive the transmitter and its outputs to the SUB FLOW (Substitute Flow described

below) state if conditions occur that cause low signal strength. A signal strength indication below 5 is

generally inadequate for measuring flow reliably, so the minimum setting for SIG C-OF is 5. A good practice

is to set the SIG C-OF at approximately 60…70% of actual measured maximum signal strength.

OTE:N The factory default Signal Strength Cutoff is 5.

If the measured signal strength is lower than the SIG C-OF setting, an error 0010 will be shown on the

transmitter’s display until the measured signal strength becomes greater than the cutoff value.

A signal strength indication below 2 is considered to be no signal at all. Verify that the pipe is full of liquid,

the pipe size and liquid parameters are entered correctly, and that the transducers have been mounted

accurately. Highly aerated liquids will also cause low signal strength conditions.

TEMP 1 C

Temperature of

RTD 1

Reported by the firmware in C°. When RTD is selected from the CH2 menu and RTDs are connected to the Energy model,

the firmware will display the temperature measured by RTD 1 in ° C.

TEMP 1 F

Temperature of

RTD 1

Reported by the firmware in F°. When RTD is selected from the CH2 menu and RTDs are connected to the Energy model, the

firmware will display the temperature measured by RTD 1 in ° F.

TEMP 2 C

Temperature of

RTD 2

Reported by the firmware in C°. When RTD is selected from the CH2 menu and RTDs are connected to the Energy model,

the firmware will display the temperature measured by RTD 2 in ° C.

TEMP 2 F

Temperature of

RTD 2

Reported by the firmware in F°. When RTD is selected from the CH2 menu and RTDs are connected to the Energy model, the

firmware will display the temperature measured by RTD 2 in ° F.

TEMP DIFF C

Temperature

difference

Reported by the firmware in C°. When RTD is selected from the CH2 menu and RTDs are connected to the Energy model,

the firmware will display the difference in temperature measured between RTD 1 and RTD 2 in ° C.

TEMP DIFF F

Temperature

difference

Reported by the firmware in F°. When RTD is selected from the CH2 menu and RTDs are connected to the Energy model, the

firmware will display the difference in temperature measured between RTD 1 and RTD 2 in ° F.

Conguration

Page 45 May 2016 TTM-UM-00136-EN-06

Loading...

Loading...