Basic Menu (BSC) continued

Parameter Meaning Options Description

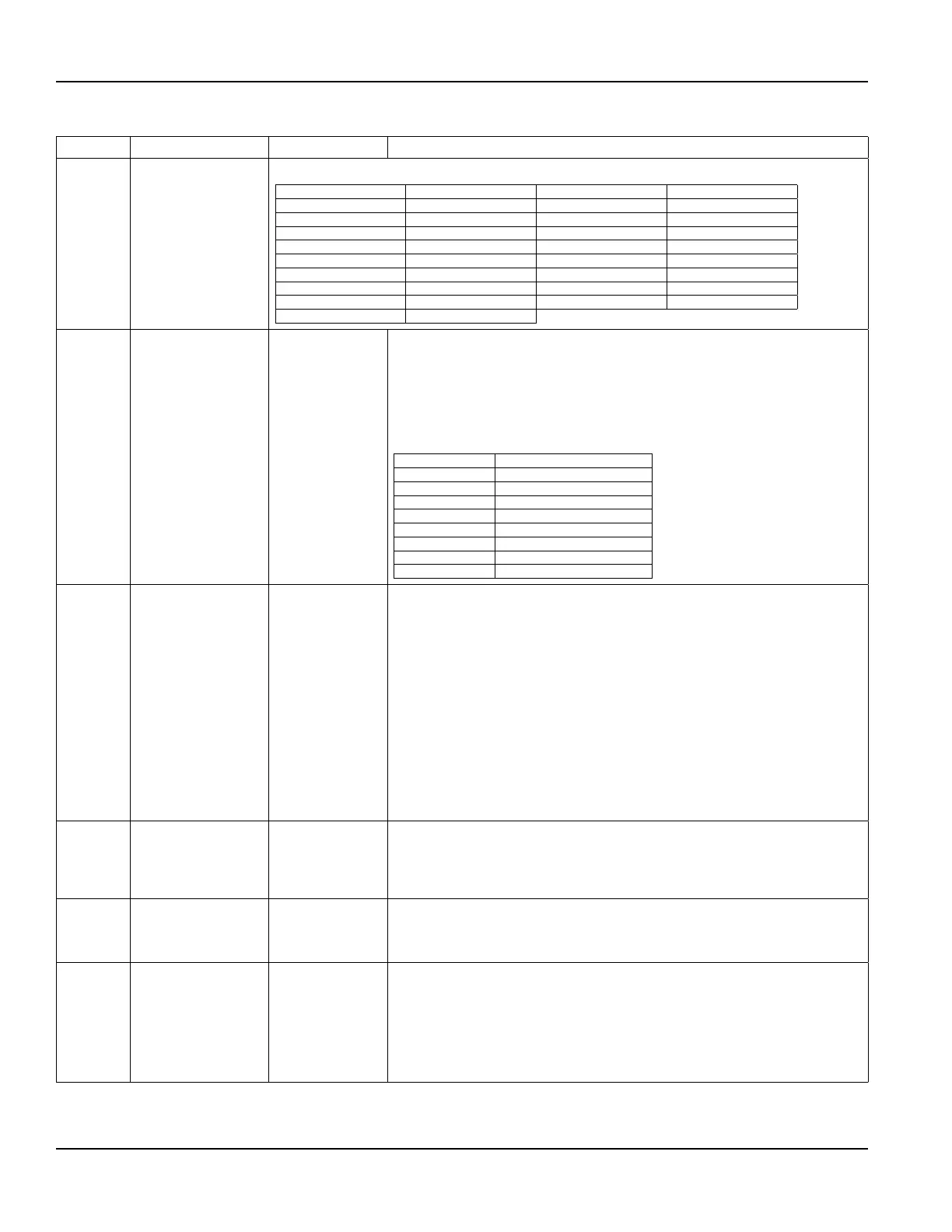

TOTL UNT Totalizer units

Select an engineering unit for flow totalizer measurements.

US Gallons US Gallons Pounds LB

Liters Liters Kilograms KG

Millions of US Gallons MGal British Thermal Units BTU

Cubic Feet Cubic Ft Thousands of BTUs MBTU

Cubic Meters Cubic Me Millions of BTUs MMBTU

Acre Feet Acre Ft 1 Ton/HR = 12000 BTU TONHR

Oil Barrels Oil Barr [42 US Gallons] Kilojoule kJ

Liquid Barrels Liq Barr [31.5 US Gallons] Kilowatt kWH

Feet Feet Megawatt MWH

Meters Meters

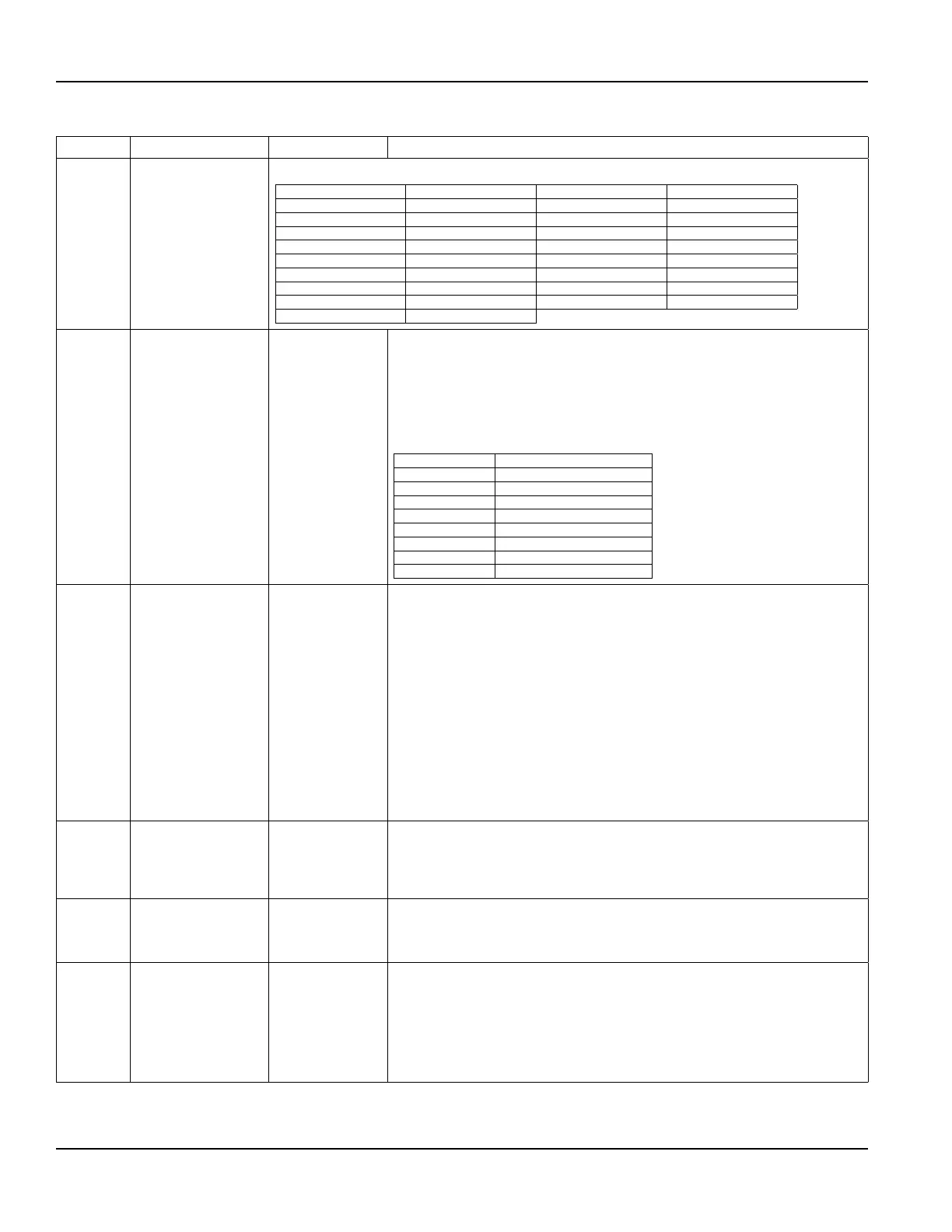

TOTL E

Flow totalizer exponent

value

E1…E6

Used for setting the flow totalizer exponent. This feature is useful for accommodating

a very large accumulated flow or to increase totalizer resolution when flows are small

(displaying fractions of whole barrels, gallons, etc.) The exponent is a × 10

n

multiplier,

where “n” can be from –1 (× 0.1)…6 (× 1000,000).

Table 8 should be referenced for valid entries and their influence on the display. Selection

of E-1 and E0 adjusts the decimal point on the display. Selection of E1, E2 and E3 causes

an icon of × 10, × 100 or × 1000 respectively to appear to the right of the total flow

display value.

Exponent Display Multiplier

E–1 × 0.1 (÷10)

E0 × 1 (no multiplier)

E1 × 10

E2 × 100

E3 × 1000

E4 × 10,000

E5 × 100,000

E6 × 1000,000

MIN RATE

Minimum flow rate

settings

(Enter a numeric

value)

A minimum rate setting is entered to establish filter software settings and the lowest

rate value that will be displayed. Volumetric entries will be in the rate units and interval

selected previously. For unidirectional measurements, set MIN RATE to zero. For

bidirectional measurements, set MIN RATE to the highest negative (reverse) flow rate

expected in the piping system.

OTE:N The transmitter will not display a flow rate at flows less than the MIN RATE value.

As a result, if the MIN RATE is set to a value greater than zero, the transmitter will

display the MIN RATE value, even if the actual flow/energy rate is less than the

MIN RATE.

For example, if the MIN RATE is set to 25 and actual rate is 0, the transmitter

display will indicate 25. Another example, if the MIN RATE is set to -100 and the

actual flow is -200, the transmitter will indicate -100. This can be a problem if

the transmitter MIN RATE is set to a value greater than zero because at flows

below the MIN RATE the rate display will show zero flow, but the totalizer which

is not affected by the MIN RATE setting will keep totalizing.

MAX RATE

Maximum flow rate

settings

(Enter a numeric

value)

A maximum volumetric flow rate setting is entered to establish filter software settings.

Volumetric entries will be in the rate units and Interval selected previously. For

unidirectional measurements, set MAX RATE to the highest (positive) flow rate expected in

the piping system. For bidirectional measurements, set MAX RATE to the highest (positive)

flow rate expected in the piping system.

FL COFF Flow cutoff

(Enter a numeric

value)

A low flow cutoff entry is provided to allow very low flow rates (that can be present when

pumps are off and valves are closed) to be displayed as zero flow. Typical values that

should be entered are between 1.0% and 5.0% of the flow range between MIN RATE and

MAX RATE.

DAMP PER System damping value 0…100%

Flow filter damping establishes a maximum adaptive filter value. Under stable flow

conditions (flow varies less than 10% of reading), this adaptive filter will increase the

number of successive flow readings that are averaged together up to this maximum

value. If flow changes outside of the 10% window, the flow filter adapts by decreasing the

number of averaged readings which allows the transmitter to react faster. Increasing this

value tends to provide smoother steady-state flow readings and outputs. If very erratic

flow conditions are present or expected, other filters are available for use in the UltraLink

software utility.

Conguration

Page 40 May 2016TTM-UM-00136-EN-06

Loading...

Loading...