Transducer Type selects the transducer that will be connected to the transmitter. Select the appropriate transducer type from

the drop-down list. This selection influences transducer spacing and transmitter performance, so it must be correct. If you are

unsure about the type of transducer to which the transmitter will be connected, consult the shipment packing list or call the

manufacturer for assistance.

OTE:N A change of transducer type will cause a system configuration error 1002: Sys Config Changed to occur. This error will

clear when the microprocessor is reset or power is cycled on the transmitter.

Transducer Mount selects the orientation of the transducers on the piping system. See “Transducer Installation” on page15

and Table 2 on page17 for detailed information regarding transducer mounting modes for particular pipe and liquid

characteristics. Whenever the transducer mounting mode is changed, a download command and subsequent microprocessor

reset or transmitter power cycle must be conducted.

Transducer Frequency selects a transmission frequency for the various types of transducers. In general, the larger the pipe the

slower the transmission frequency needs to be to attain a good signal.

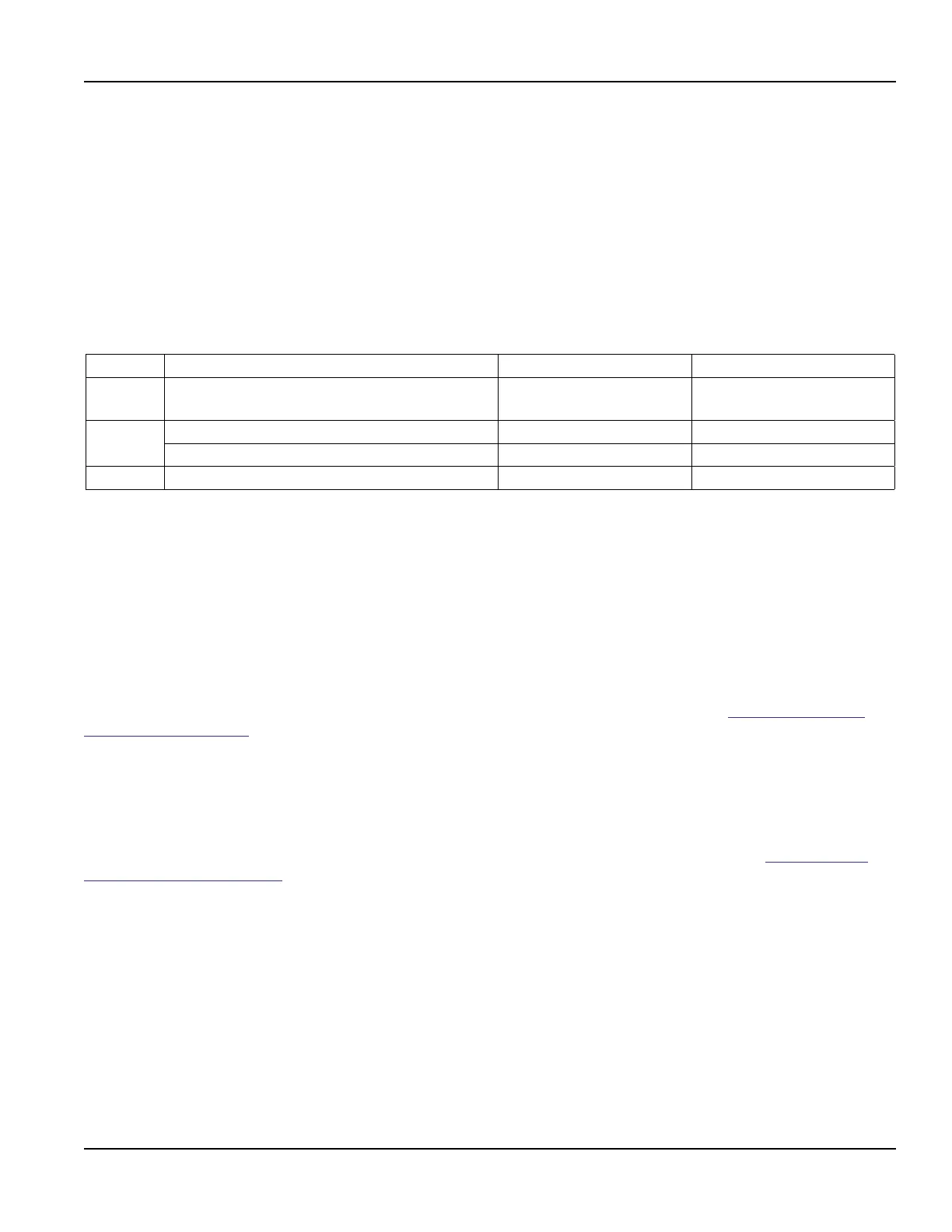

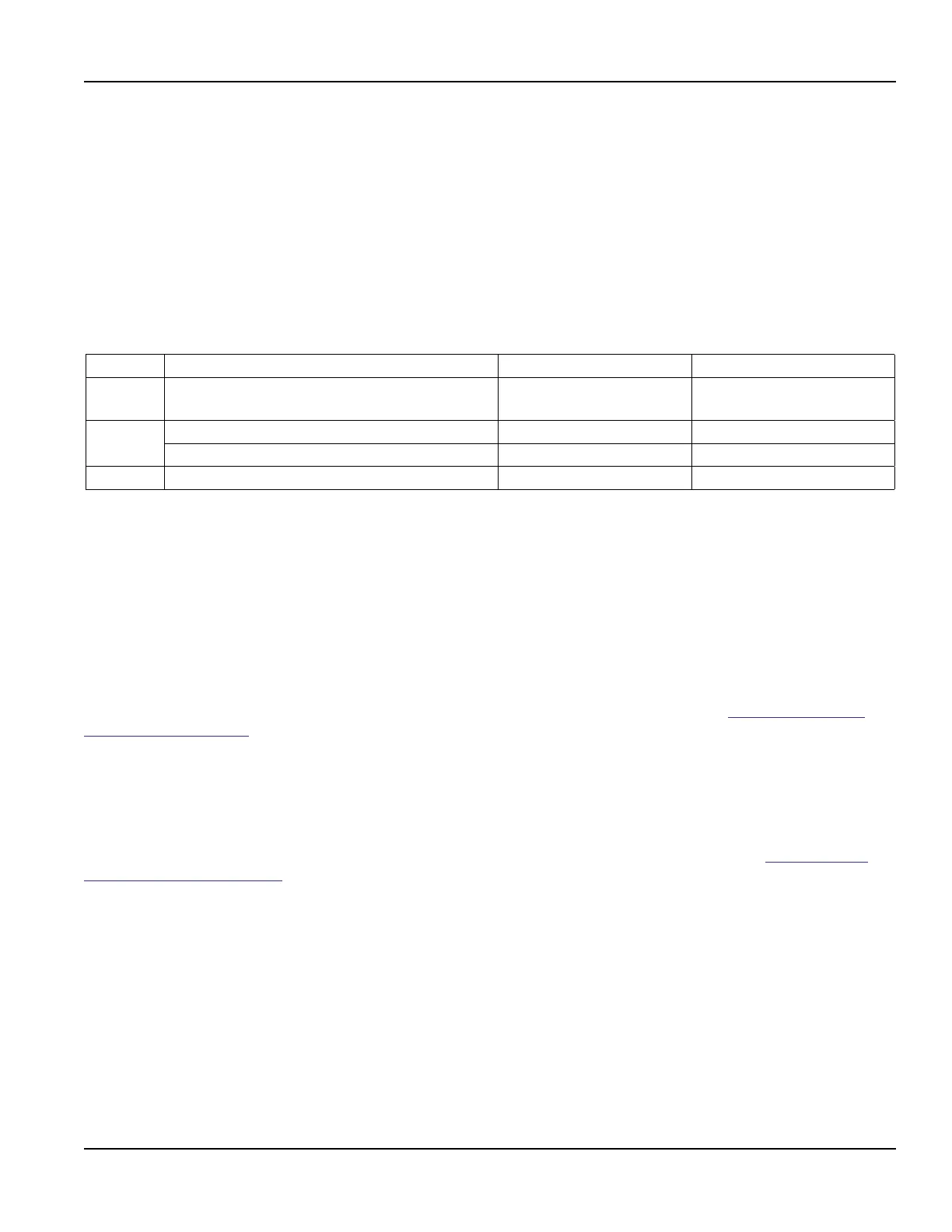

Frequency Transducers Mounting Modes Pipe Size and Type

2 MHz

All 1/2…1-1/2 in. Small Pipe and Tube

2 in. Tubing

Selected by Firmware Specific to Transducer

1 MHz

2 in. ANSI Pipe and Copper Tube Selected by Firmware Specific to Transducer

Standard and High Temp W, V, and Z 2 in. and Greater

500 kHz Large Pipe W, V, and Z 24 in. and Greater

Table 8: Transducer Frequencies

Transducer Spacing is a value calculated by the transmitter’s firmware that takes into account pipe, liquid, transducer and

mounting information. This spacing will adapt as these parameters are modified. The spacing is given in inches for English

units selection and millimeters for metric. This value is the lineal distance that must be between the transducer alignment

marks. Selection of the proper transducer mounting method is not entirely predictable and many times is an iterative process.

OTE:N This setting only applies to DTTR, DTTN, DTTL and DTTH transducers.

Transducer Flow Direction allows the change of the direction the transmitter assumes is forward. When mounting transmitters

with integral transducers, use this feature to reverse upstream and downstream transducers, making upside-down mounting

of the display unnecessary.

Select a Pipe Material the pull-down list. If the pipe material used is not found in the list, select Other and enter the actual

pipe material Sound Speed and Roughness (much of this information is available at web sites such as www.ondacorp.com/

tecref_acoustictable.html) for pipe relative roughness calculations.

Pipe O.D. and Wall Thickness are based on the physical dimensions of the pipe on which the transducers will be mounted.

Enter this value in inches for English units or millimeters for metric units.

OTE:N See “North American Pipe Schedules” on page110 for charts listing popular pipe sizes. Correct entries for pipe O.D.

and pipe wall thickness are critical to obtaining accurate flow measurement readings.

Liner Material is selected from the pull-down list. If the pipe liner material used is not included in the list, select Other and

enter liner material Sound Speed and Roughness (much of this information is available at web sites such as www.ondacorp.

com/tecref_acoustictable.html). See “Liner material relative roughness” on page 38 for pipe liner relative roughness calculations.

Fluid Type is selected from a pull-down list. If the liquid is not found in the list, select Other and enter the liquid Sound Speed

and Absolute Viscosity into the appropriate boxes. The liquid’s specific gravity is required if mass measurements are to be

made, and the specific heat capacity is required for energy measurements.

Use the RS485 Communications option to change the RS485 Baud Rate and BACnet MSTP Device ID (used in the Microchip

communications microcontroller).

Conguration Menu

Page 51 May 2016 TTM-UM-00136-EN-06

Loading...

Loading...