Parameters

92 M-Max Series Adjustable Frequency Drive MN04020003E—October 2013 www.eaton.com

Motor Heat Protection (P8.6–P8.9)

The motor temperature protection is based on a calculated

temperature model and uses the motor current set in

parameter P7.1 to determine the motor load. It does not use

a temperature measurement in the motor.

The calculated temperature model cannot protect the motor

if the cooling flow to the motor is influenced, for example, by

a blocked air entry-way.

The temperature model is based on the assumption that the

motor achieves a winding temperature of 284°F (140°C) at

rated speed and an ambient temperature of 104°F (40°C),

with 105% rated load.

The cooling efficiency, without external cooling, is a function

of the speed (corresponding with the output frequency of the

frequency inverter). When the motor is stationary (zero

frequency), heat is also dissipated through the housing surface.

When the motor is under a great load, the current required by

the motor can be higher than the rated operational current.

The current provided by the frequency inverter can be higher

than the rated operational current of the motor. If the load

requires this much current, there is a danger of a thermal

overload. This is especially the case at lower frequencies

(<25 Hz). Here, the cooling effect (speed of the motor fan)

and the load rating of the motor (see data sheet of the motor)

are reduced similarly with lower frequencies. On motors that

are equipped with an external fan, there is less of a load

reduction at lower speeds.

With parameters P8.6 to P8.9, a motor temperature protection

can be set for the M-Max frequency inverter which protects

the motor from overheating. The temperature protection is

calculated. A direct temperature measuring in the windings

of the motor (see thermistor protection) offers great protection.

The reaction of the M-Max frequency inverter to a

detected thermal overload can be set via parameter P8.6.

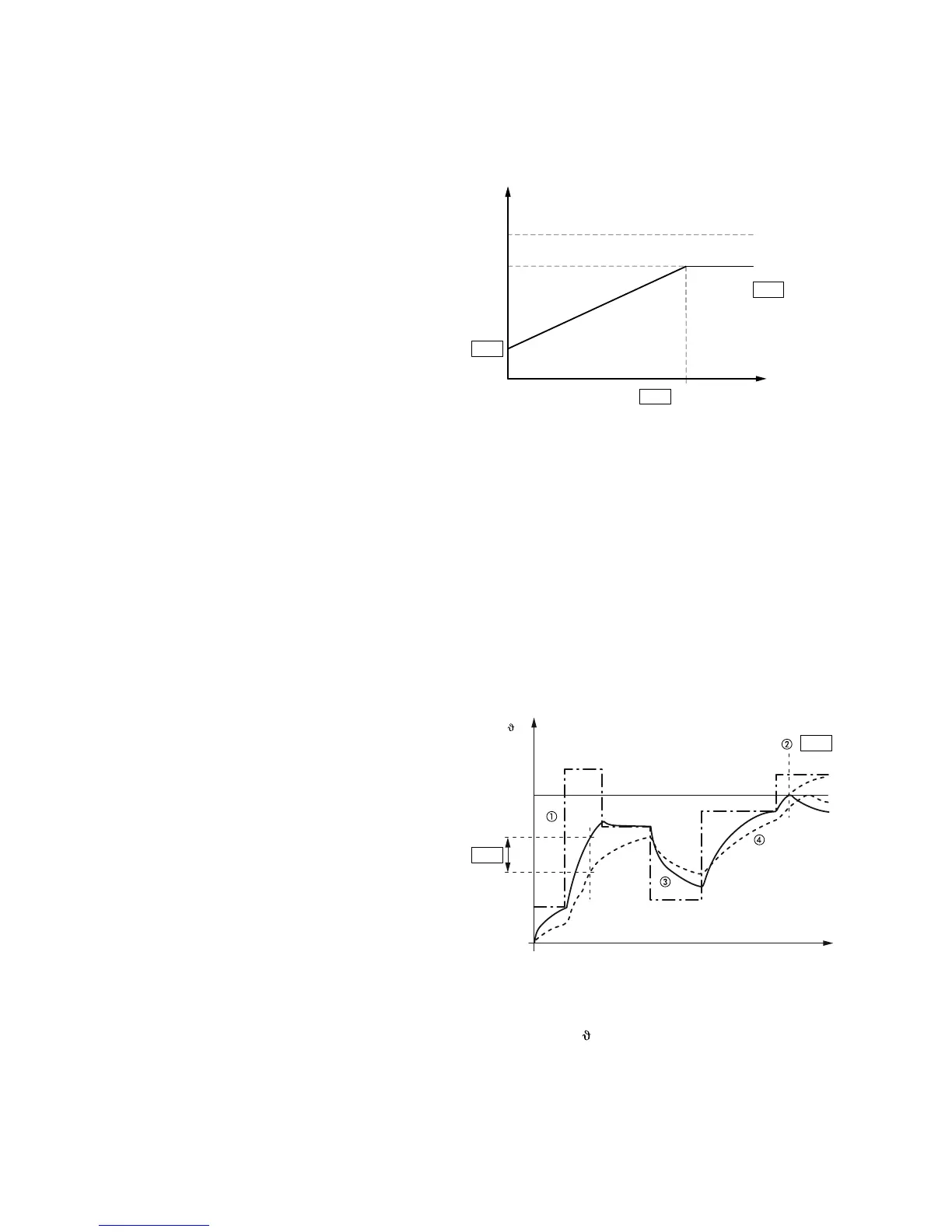

At parameter P8.8 you can set the cooling output (P

Cool

)

on the motor at zero frequency (standstill). Note the

specifications of the motor manufacturer.

Possible setting values are 0–150% of the cooling output at

the rated frequency f

N

(see nameplate of the motor = P7.6).

If the protection function is deactivated (P8.6 = 0), the

temperature model of the motor is reset to zero.

The thermal current I

th

corresponds with the load current at

maximum thermal load rating on the motor. In continuous

operation, at rated frequency (f

N

= P7.6) and rated loading,

the value of I

th

corresponds with the rated operational

current of the motor (see the motor rating plate = P7.1).

Motor Cooling Power

The time constant for the motor temperature (P8.9) defines

how long it takes until the temperature has achieved 63% of

its end value in the motor. In practice, this temperature time

is constant depending on the type and design of the motor. It

varies between the different design sizes at the same shaft

power and between the different motor manufacturers.

The larger a motor is, the greater the time constant. The

factory set value (P8.9 = 45 min) can be set in the range

between 1 and 200 minutes. The guide value is twice t

6

time

of a motor. The t

6

time defines the time in seconds in which

a motor can be operated safely at six times the rated

operational current (see data sheet of the motor,

manufacturer specifications).

If the drive is stopped, the time constant is increased

internally to three times the set parameter value (P8.9).

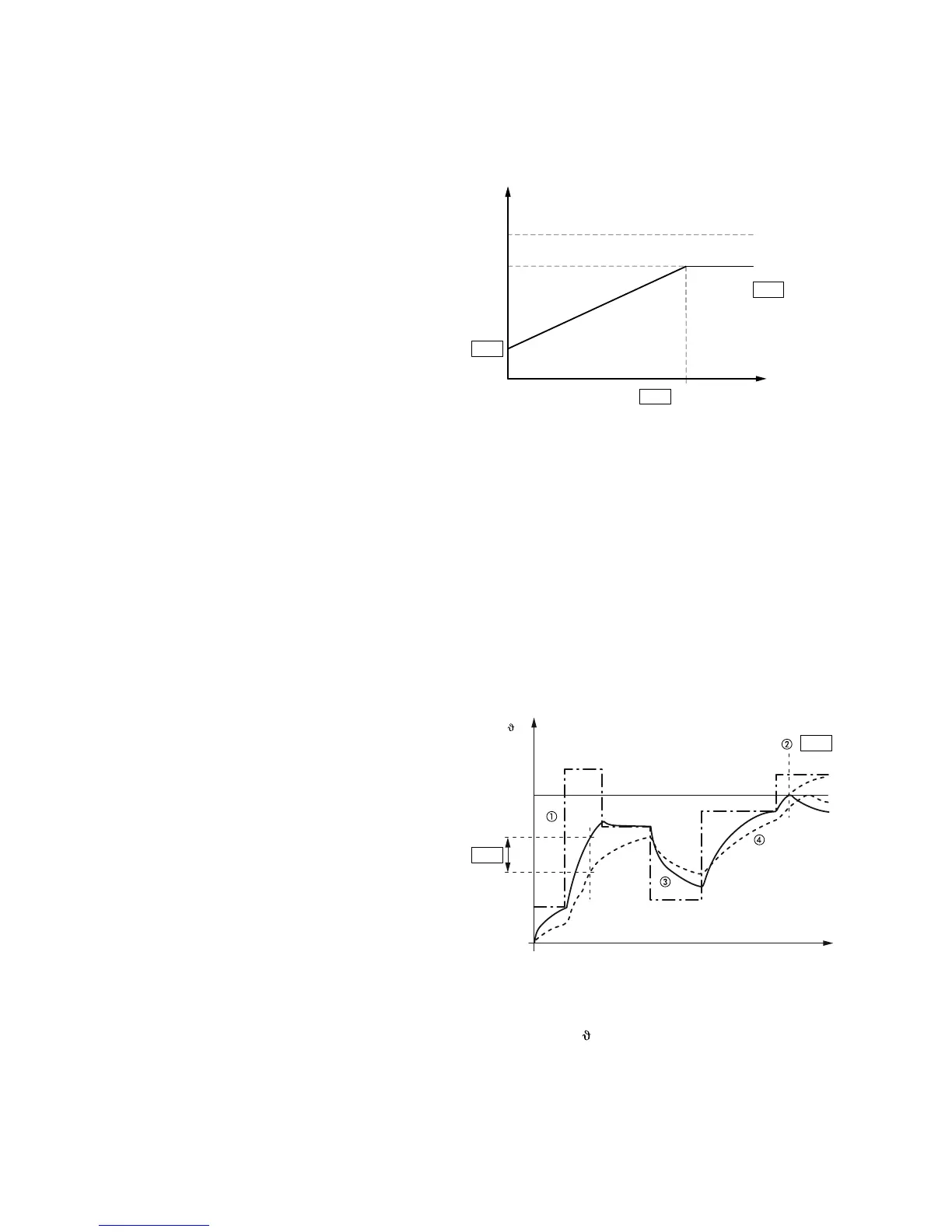

Calculation of Motor Temperature

Notes

Motor current I/I

T

.

Trip value shut-off (error message) or warning according to P8.6.

Calculated value for the motor temperature Q = (I/I

T

)

2

x (1 - e

-t/T

).

Motor temperature

M

(example).

P8.9 = Motor temperature time constant (T).

P7.6

f

N

P8.8

100%

150%

P

Cool

P7.1

I

th

f (Hz)

t

105%

P8.9

P8.6

M

Loading...

Loading...