Parameters

M-Max Series Adjustable Frequency Drive MN04020003E—October 2013 www.eaton.com 95

PID Controller (P9)

The M-Max series frequency inverters are provided with a

PID controller that you activate with P9.1 = 1. The controller

can be deactivated via a digital input (P3.12).

PID control is superimposed on the frequency inverter

function. You should therefore set all of the frequency

inverter’s drive-related parameters, such as maximum output

frequency (motor speed), acceleration and deceleration

ramps (mechanical load, belts). Frequency inverter and motor

are process-integrated actuators. The output frequency to

the motor (which determines the speed) is specified as

manipulated variable from the PID controller.

When the PID controller is activated, the setpoints and actual

values become process variables and are normalized

automatically into percentages (%). For example, the

specified setpoint (0–100%) here is the same as a volume

flow (0–50 m

3

/h). The actual value here is the volume flow

(m

3

/h) from a suitable sensor, which is evaluated again as a

percentage (0–100%).

If this process data is to be displayed in the physical variable

(m

3

/h), you can set the conversion with parameter P9.19

(see “Display factor (P9.19)”).

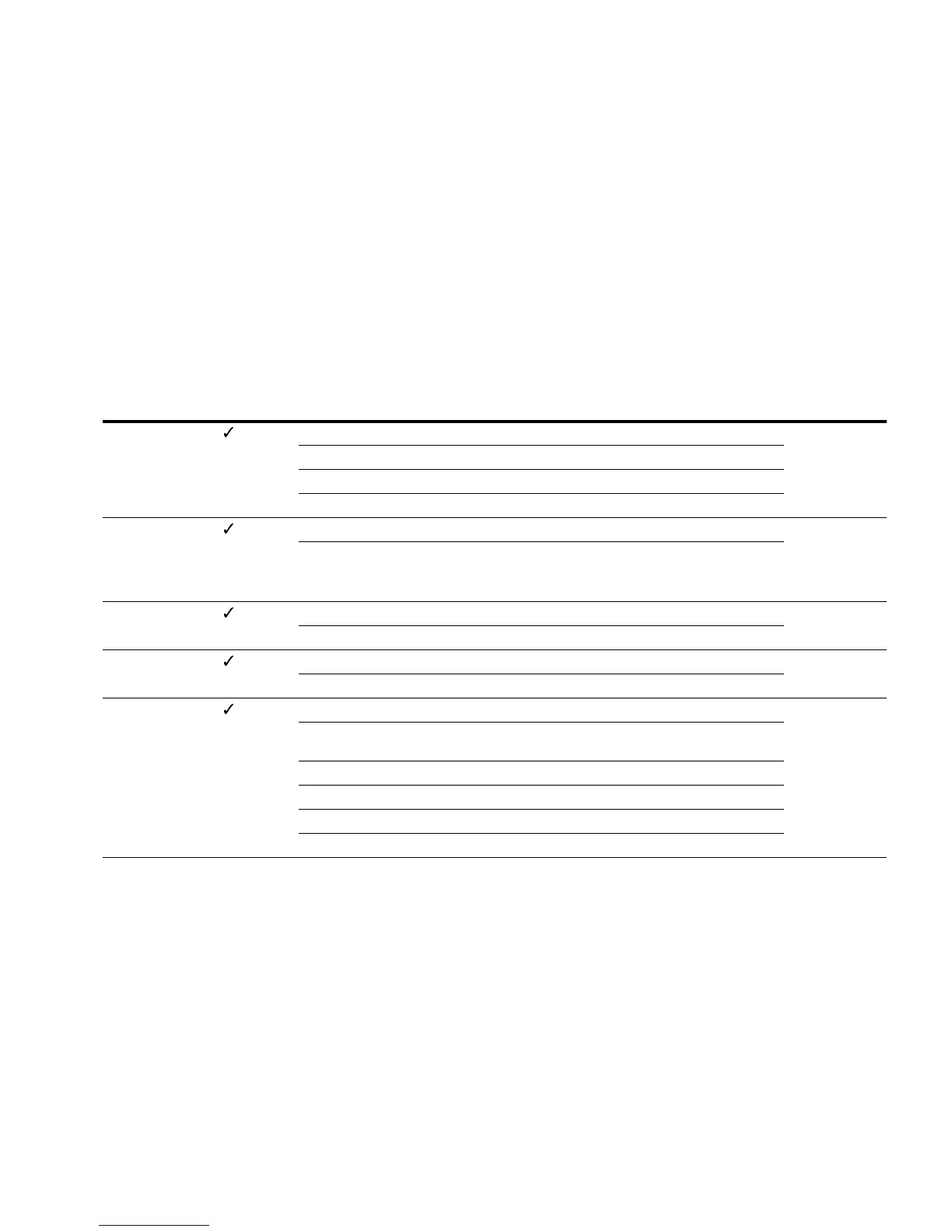

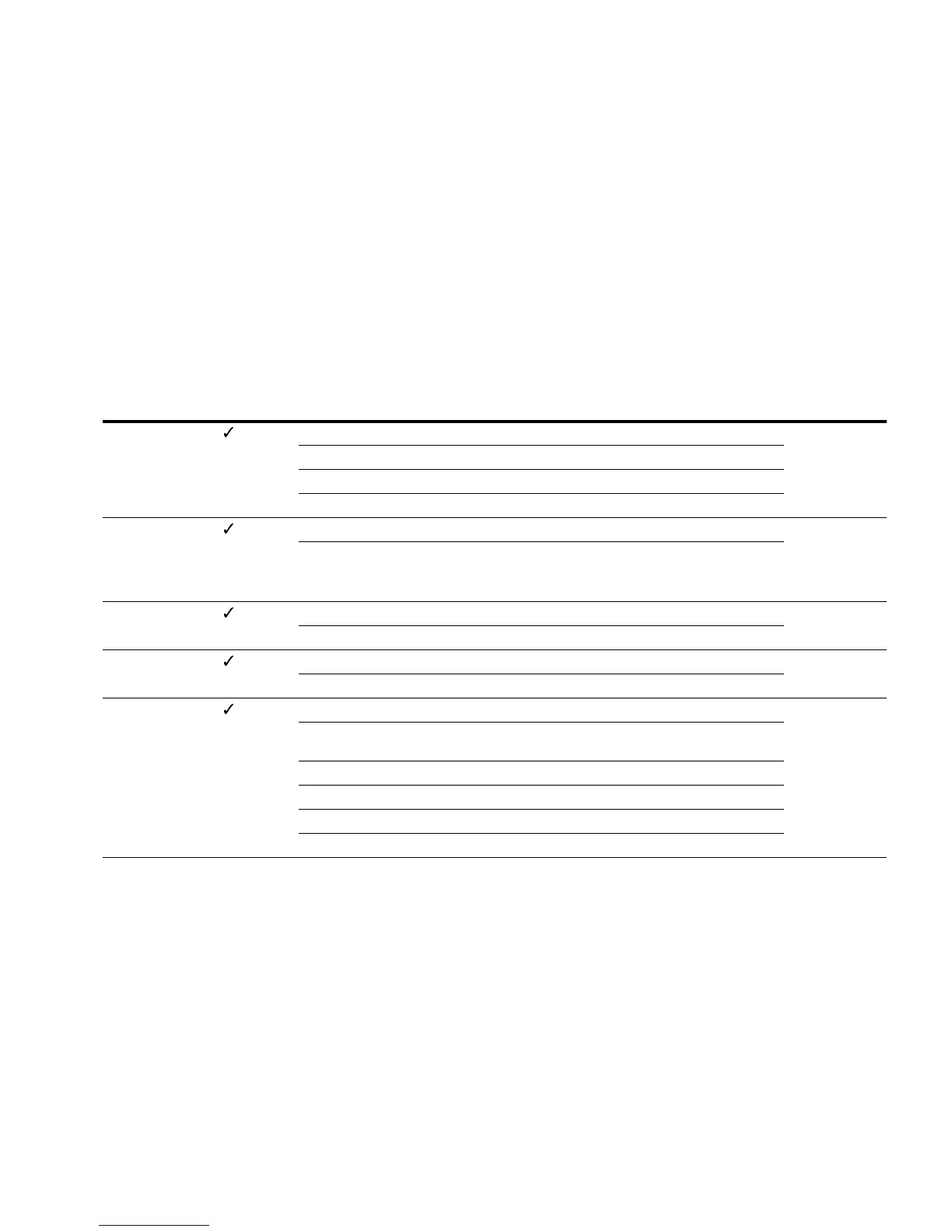

PID Controller

PNU ID

Access

RUN Value/Range Description

Factory Setting

(P1.3)

P9.1 163 — PID Controller 0

0 Deactivated

1 Activated for drive control

2 Activated for external application

P9.2 118 — PID controllers, P gain 100

0–1000% Proportional Gain (KP)

Low values attenuate the control action

High values can cause oscillation

P9.3 119 — PID controller, I reset time 10.0

0–320s Integral time constant

P9.4 167 — PID controller setpoint, keypad reference 0.0

0–100% Setpoint setting range utilizing keypad as reference P9.5 = 0

P9.5 332 — PID controller, setpoint source 0

— The setting range is limited by P6.3 (raised starting frequency)

and P6.4 (end frequency)

0 Keypad (P9.4)

1 Fieldbus

2 AI1

3 AI2

Loading...

Loading...