Parameters

M-Max Series Adjustable Frequency Drive MN04020003E—October 2013 www.eaton.com 115

Regenerative Braking

If the rotor of an asynchronous motor is driven

oversynchronously in the direction of the rotating field, it

generates electric power via its stator windings. The motor

becomes a generator. In the frequency inverter, this

generative energy causes an increase in the DC link voltage.

Oversynchronous speeds occur, for example, when the

output frequency in frequency inverter operation is reduced

with short deceleration times, the connected machine has a

large flywheel mass, or when the flowing medium in pumps

and fans works against the speed reduction.

The rise in the DC link voltage is monitored by the M-Max

frequency inverter and always enables a braking torque of

around 30% of the motor rated torque. A higher braking

torque can be achieved by selecting a more powerful

frequency inverter. From the 1.1 kW (3.3A at 400V =

MMX34AA3D3_) rating, the internal brake chopper with an

external power resistor enables up to 100% of the rated

motor torque.

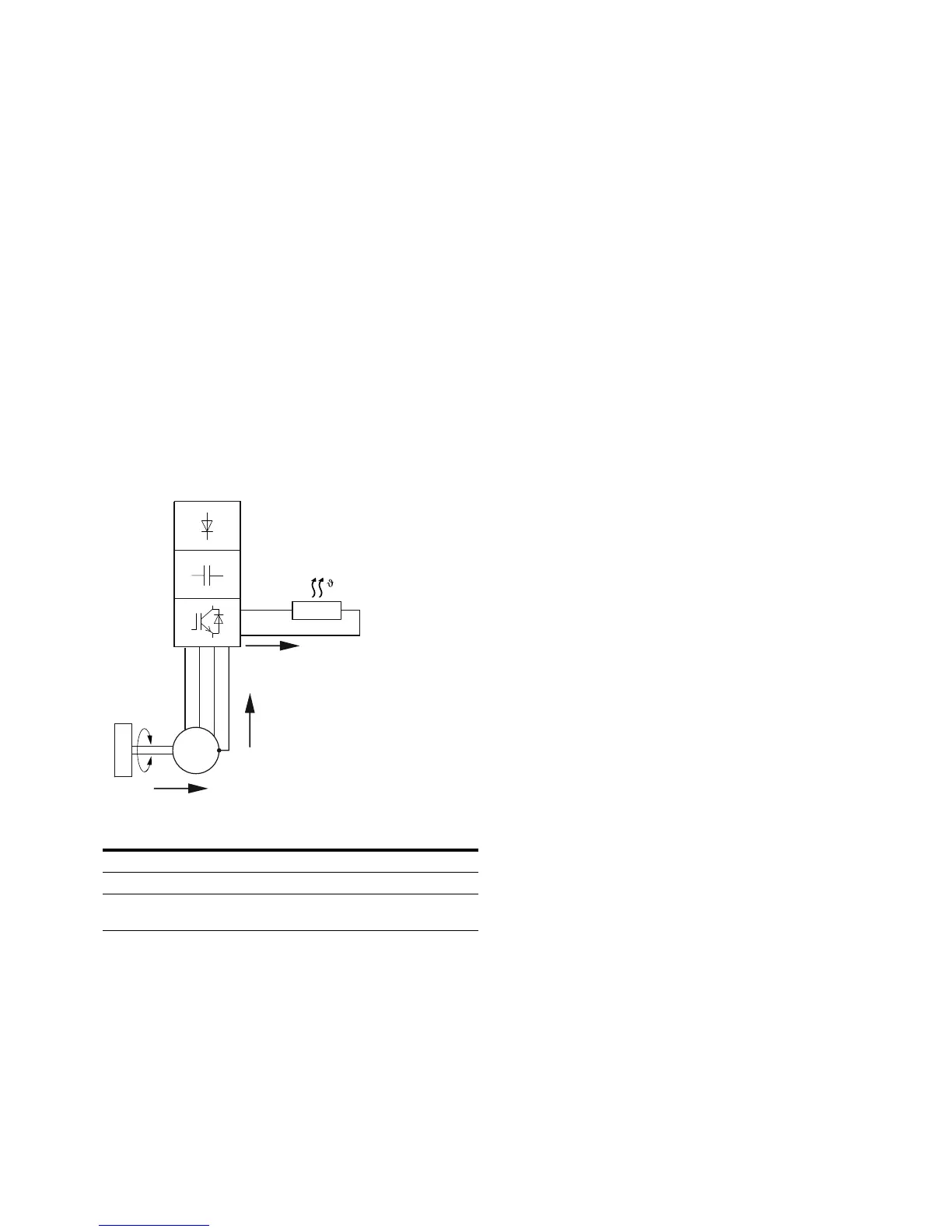

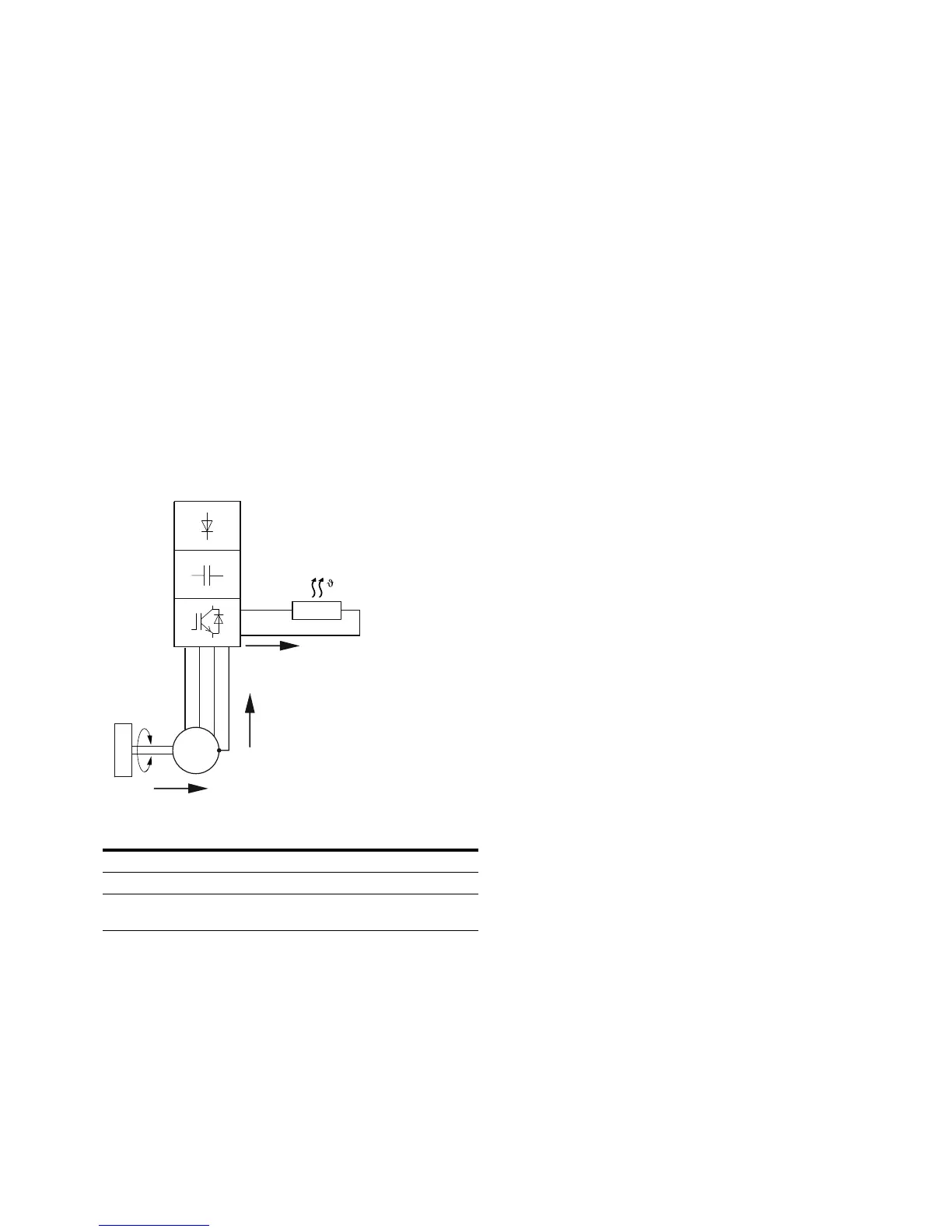

Regenerative Braking with External Braking Resistor

The brake chopper can be activated at parameter P12.5. This

function is only activated with the three-phase frequency

inverters MMX34…3D3_ (3.3A) to MMX34…014_ (14A).

These ratings have an internal brake transistor that can

dissipate excess brake energy via an external power resistor

(connection terminals R+ and R–) when large flywheel

masses or short deceleration times are involved.

This parameter is not visible with frequency inverters without

a braking transistor.

Item

Number Description

1 Machine flywheel mass

2 Inverter with brake chopper (brake transistor)

3 Brake resistor (RB)

See Energy Flow (brake torque)

M

R

B

3 ~

R+

R–

1

2

3

Loading...

Loading...