Engineering

22 M-Max Series Adjustable Frequency Drive

MN04020003E—October 2013 www.eaton.com

The leakage current to ground is greater than 3.5 mA with a

frequency inverter. Based on the requirements of EN 50178,

an increased ground (PE) has to be connected. The cable

cross-section must be at least 10 mm

2

or consist of two

separately connected ground cables.

Residual current circuit breakers must be suitable for:

●

the protection of installations with DC current component

in case of fault scenario (RCD type B)

●

high leakage currents (300 mA)

●

brief discharges of pulse current spikes

Input Contactor

The input contactor enables an operational switching on and

off of the supply voltage for the frequency inverter, and

switching off in case of a fault.

The input contactor is designed based on the input current

(I

LN

) of the frequency inverter and the utilization category

AC-1 (IEC 60947). Input contactors and the assignment to

M-Max frequency inverters are explained in the appendix.

While planning the project, make sure that inching operation

is not done via the input contactor of the frequency inverter

on frequency-controlled drives, but through a controller input

of the frequency inverter.

The maximum permitted operating frequency of the input

voltage with the M-Max frequency inverter is one time per

minute (normal operation).

EMC Measures

Electrical components in a system (machine) have a

reciprocal effect on each other. Each device not only emits

interference but is also affected by it. The interference can

be produced by galvanic, capacitive, and/or inductive

sources, or by electromagnetic radiation. In practice, the limit

between line-conducted interference and emitted

interference is around 30 MHz. Above 30 MHz, cables and

conductors act like antennas that radiate electromagnetic

waves.

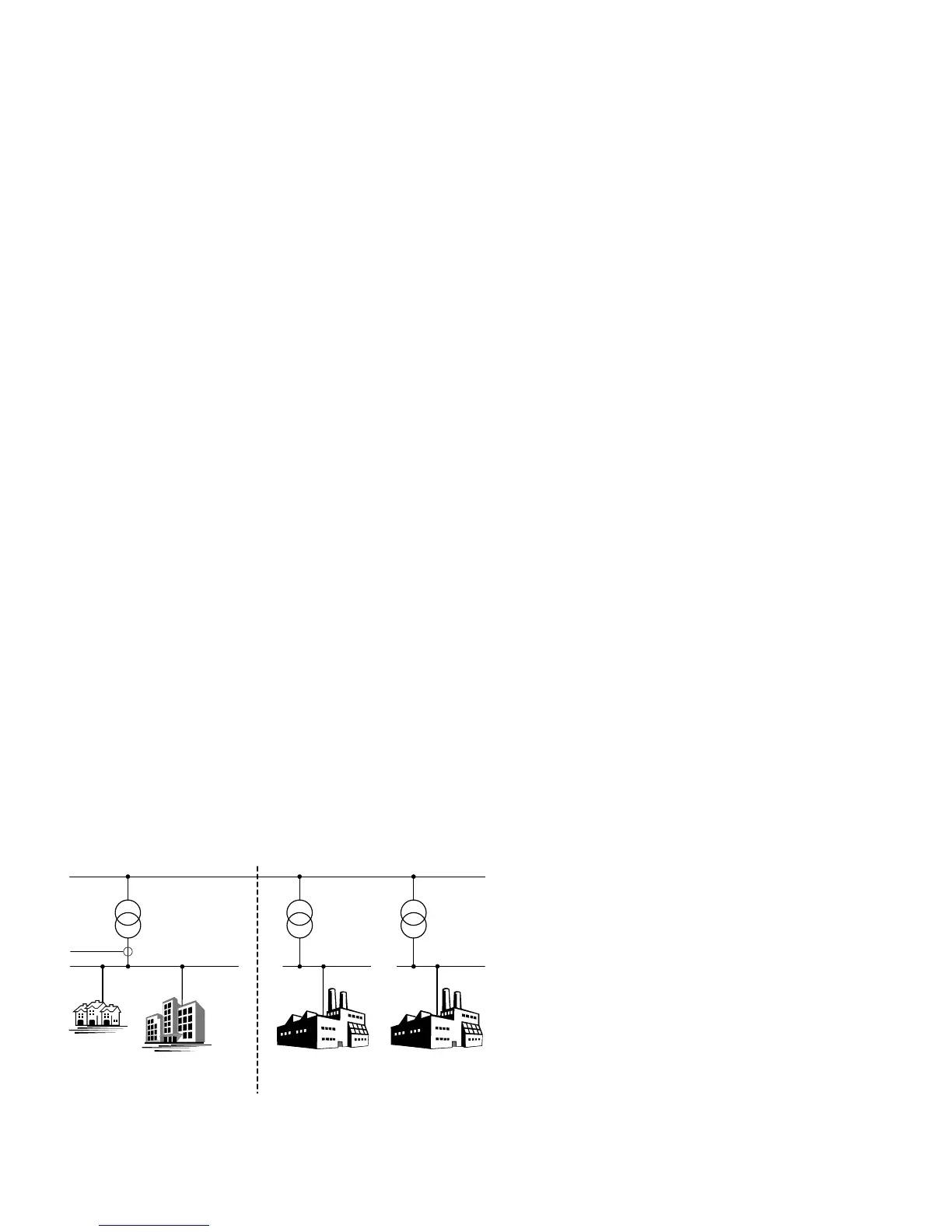

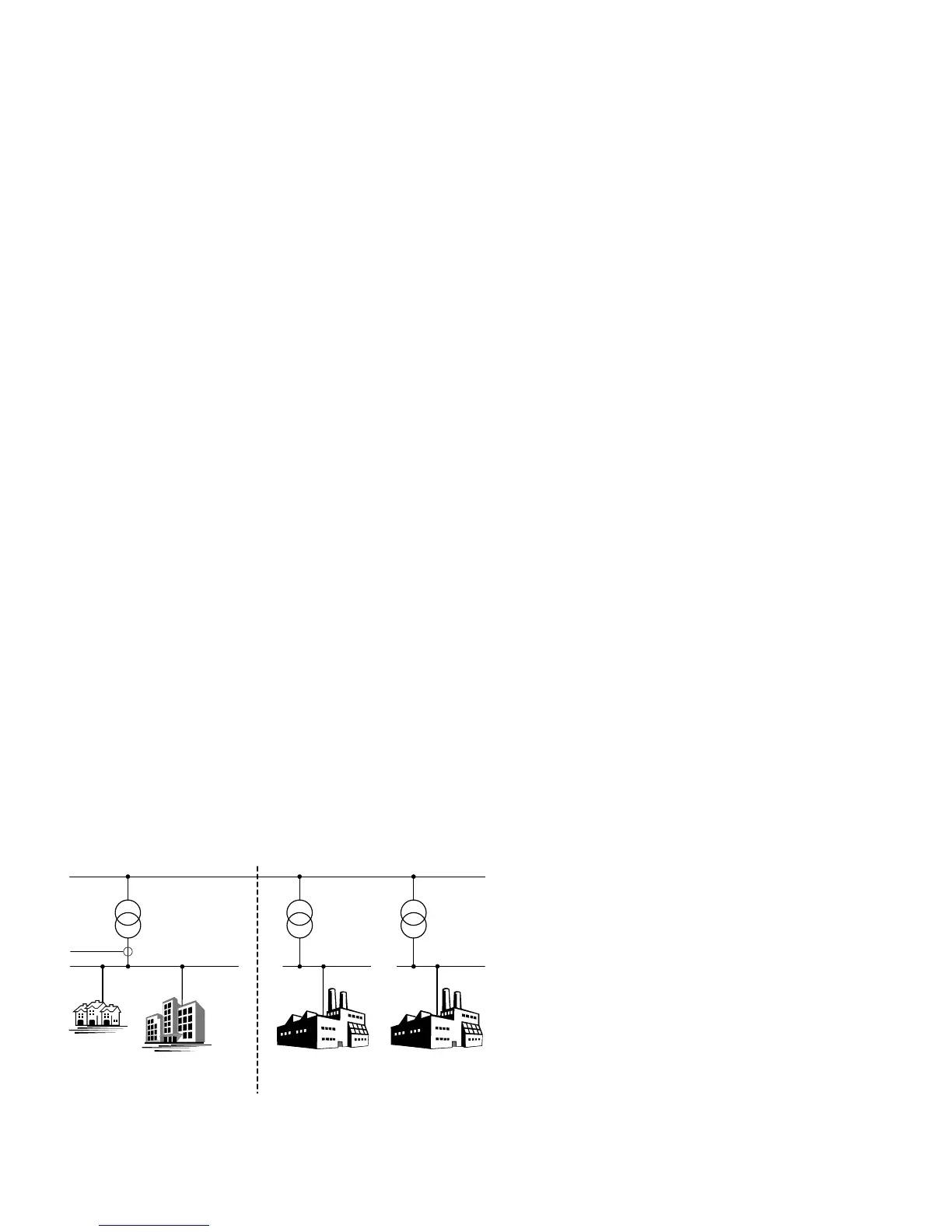

Electromagnetic compatibility (EMC) for frequency controlled

drives (variable speed drives) is implemented in accordance

with product standard IEC/EN 61800-3. This includes the

complete power drive system (PDS), from the input supply to

the motor, including all components, as well as cables (see

figure on

Page 18

). This type of drive system can consist of

several individual drives.

The generic standards of the individual components in a PDS

compliant with IEC/EN 61800-3 do not apply. These

component manufacturers, however, must offer solutions

that ensure standards-compliant use.

In Europe, maintaining the EMC guidelines is mandatory.

A declaration of conformity (CE) always refers to a “typical”

power drive system (PDS). The responsibility to comply with

the legally stipulated limit values and thus the provision of

electromagnetic compatibility is ultimately the responsibility

of the end user or system operator. This operator must also

take measures to minimize or remove emission in the

environment concerned (see figure below). He must also use

means to increase the interference immunity of the devices

of the system.

With their high interference immunity up to category C3,

M-Max frequency inverters are ideal for use in harsh

industrial networks (2nd environment).

With line-conducted emission, type MMX…-F_ frequency

inverters (with integrated interference suppression filter)

ensure the observance of the sensitive limit values of

category C2 in environment 1. This requires an

EMC-compliant installation (see

Page 32

) and the

observance of the permissible motor cable lengths and

maximum switching frequency (f

PWM

) of the inverter.

Type MMX…-N_ frequency inverters can comply with the

limit values of category C1 in environment 1 when used in

conjunction with an assigned external interference

suppression filter.

The required EMC measures should be taken into account in

the engineering phase. Improvements and modifications

during mounting and installation or even at the installation

site involve additional and even considerably higher costs.

EMC Environment and Category

Public Medium-Voltage Supply Grid

Public

Low-Voltage

Supply Grid

Industry

Grid 1

Industry

Grid 2

Measuring

Point

Category C1

Category C1/C2 Category C3/C4 Category C3/C4

1

st

Enviroment 2

nd

Enviroment

Loading...

Loading...