Installation

M-Max Series Adjustable Frequency Drive MN04020003E—October 2013 www.eaton.com 35

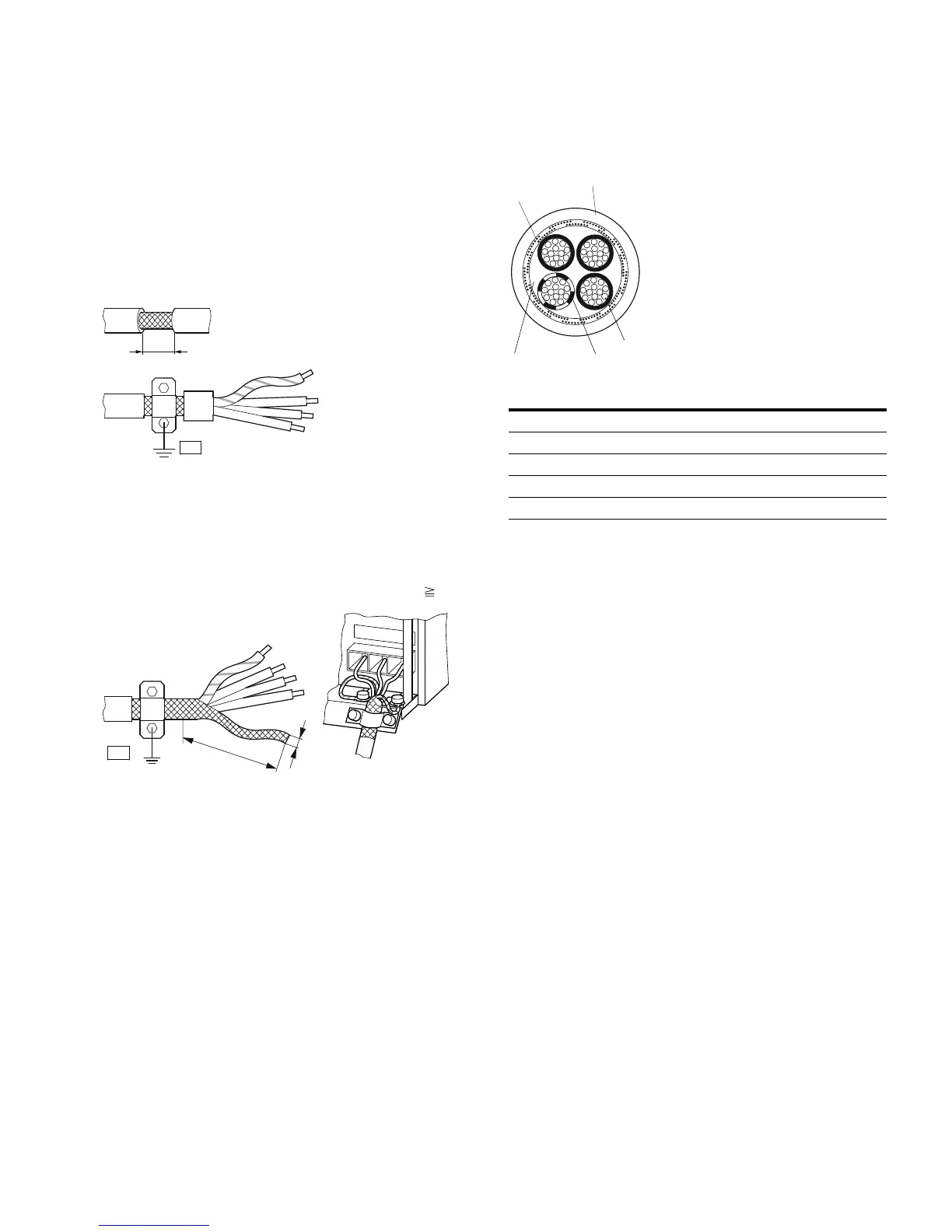

Prevent the shielding from becoming unbraided, for example,

by pushing the separated plastic covering over the end of the

shielding or with a rubber grommet on the end of the

shielding. As an alternative, in addition to a broad area cable

clip, you can also twist the shielding braid at the end and

connect to protective ground with a cable clip. To prevent

EMC disturbance, this twisted shielding connection should

be made as short as possible (see figure below).

Screened Connection Cable

Shielded, four-wire cable is recommended for the motor

cables. The green-yellow line of this cable connects the

protective ground connections from the motor and the

frequency inverter and therefore minimizes the equalizing

current loads on the shielding braid.

Connection with Twisted Cable Shielding

(Recommended value for twisted cable shielding: b 1/5 a)

Twisted shielding braid should be connected with a ring

cable terminal (see figure on Page 33) on PES.

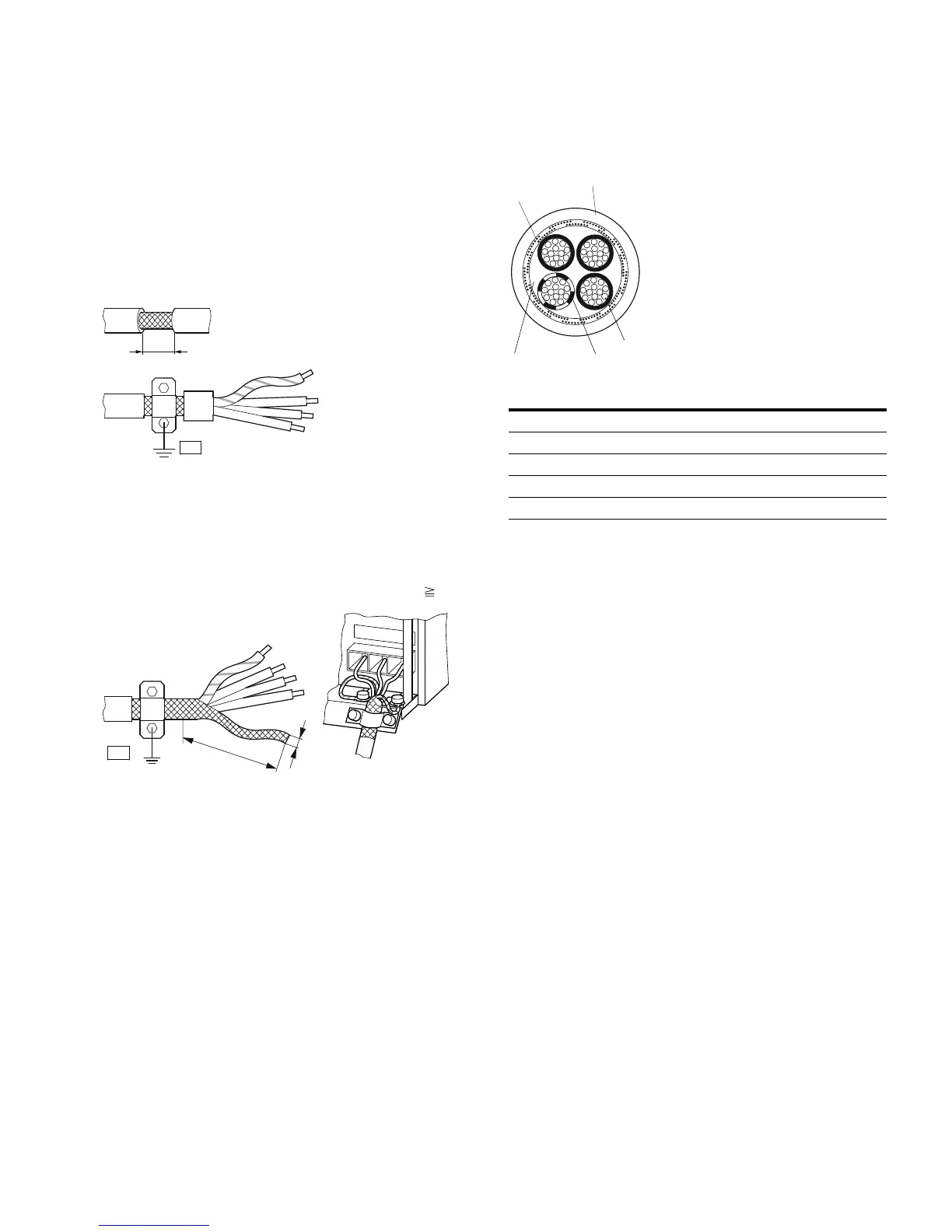

The following figure shows the construction of a four-wire,

shielded motor line (recommended specifications).

Four-Core Shielded Motor Supply Cable

If there are additional subassemblies in a motor circuit (for

example, motor contactors, relays, motor reactor, sinusoidal

filters, or terminals), interrupt the shielding of the motor

cable in the vicinity of these subassemblies. Connect this

over a broad surface area with the mounting plate (PES).

Free or non-shielded connection cables should not be any

longer than about 11.81 in (300 mm).

0.59 in

(15 mm)

PES

U/T1

V/T2

W/T3

a

b

PES

Item

Number Description

1 Cu shield braid

2 PVC outer sheath

3 Drain wire (copper strands)

4 PVC core insulation, 3 x black, 1 x green–yellow

5 Textile and PVC fillers

1

2

3

45

Loading...

Loading...