the way this “trigger” can be interpreted by the system, but usually a message is printed in

response to a signal from the photocell.

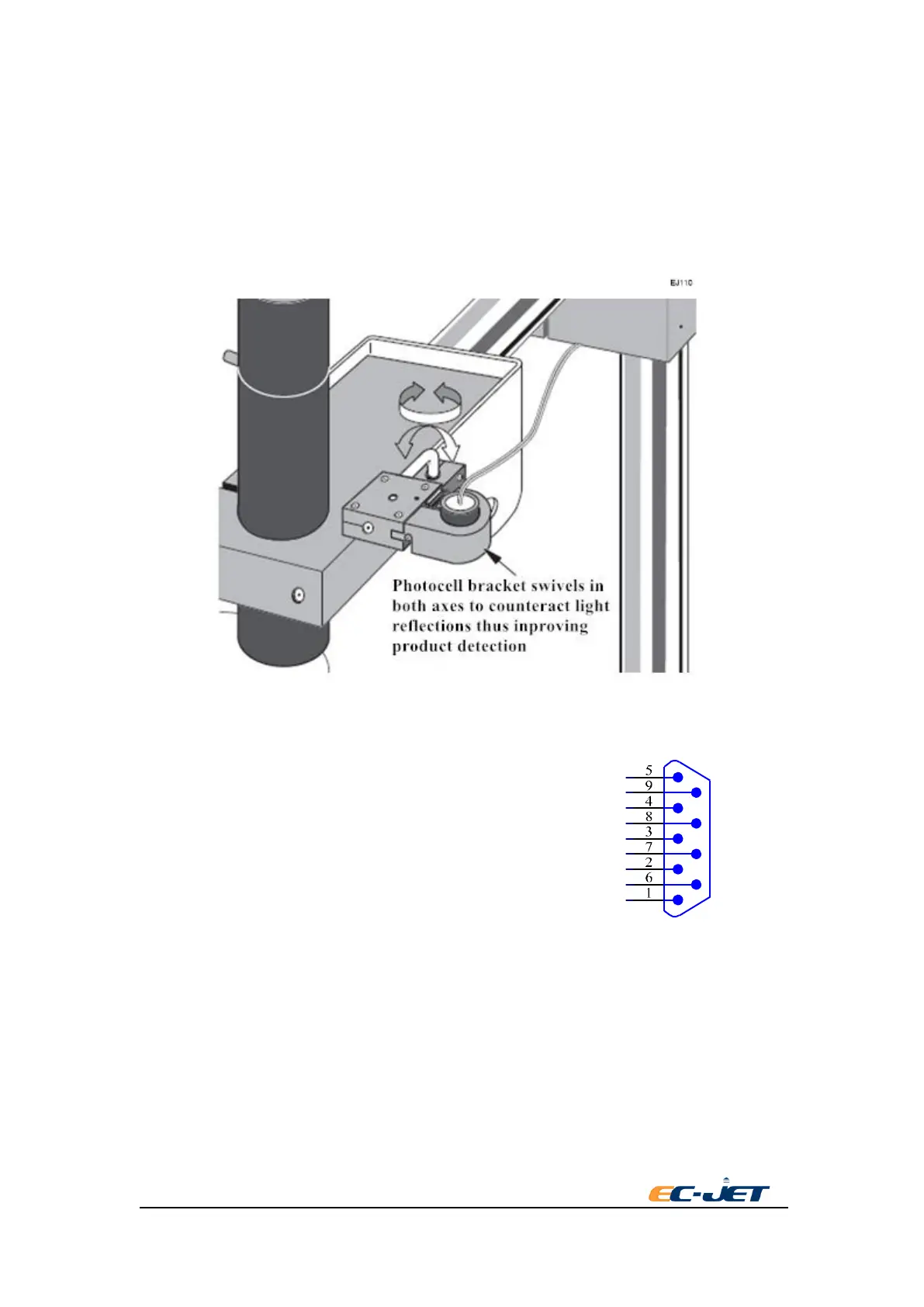

The photocell should be mounted upstream of the print head (so it detects the product before the

product reaches the print head), as close to the print head as possible and at a distance from the

product which gives consistently reliable triggering when a product passes it. A delay between the

photocell being triggered and the print taking place can be set by a menu command, to aid fine

adjustment of print positioning on the product.

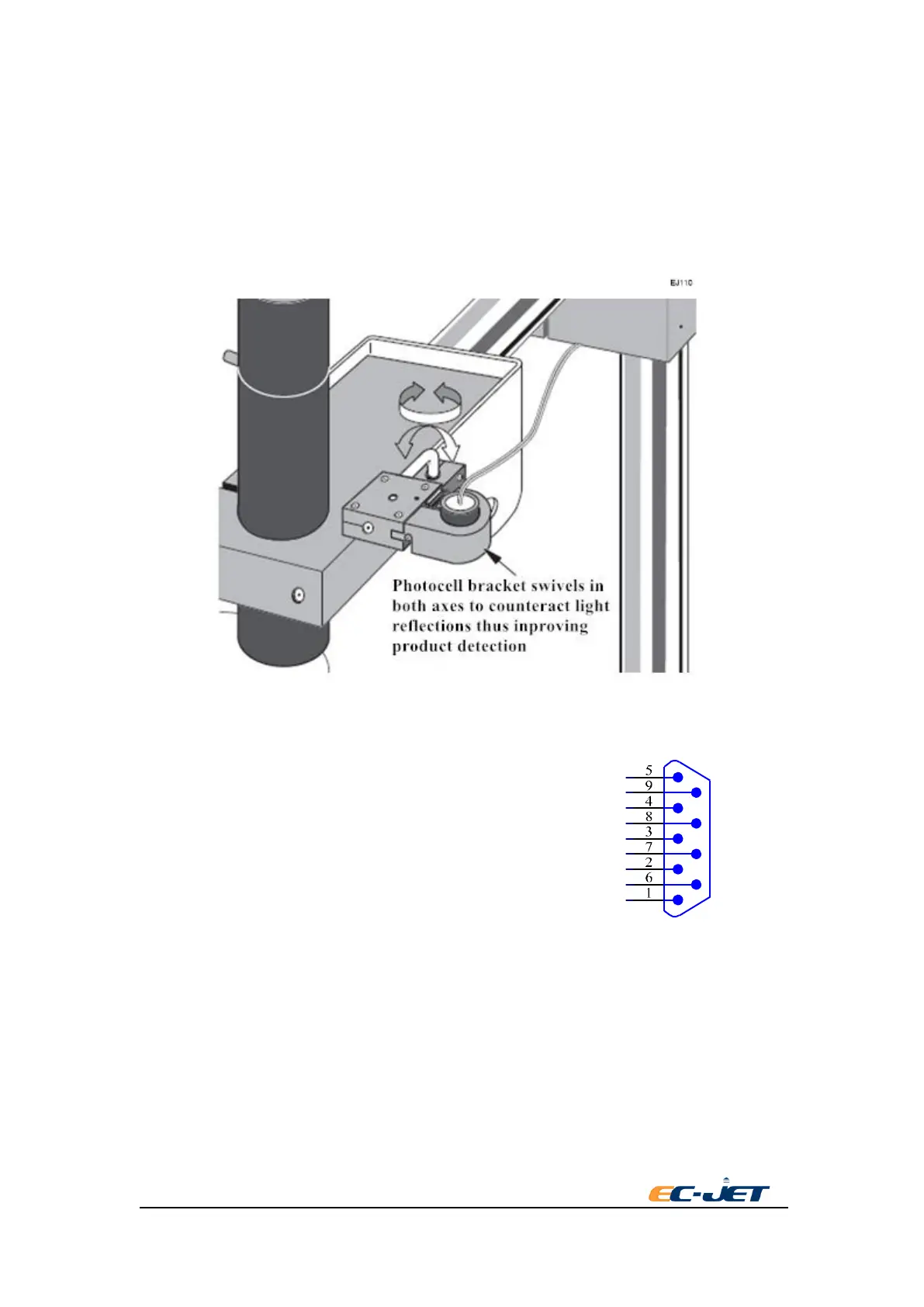

1.6.1 Photocell Connections

The photocell is connected to the system via a 9-pin D - Type connector. The function of each pin

is described below:

Pin 1 + 24volts

Pin 2 0 volts

Pin 3 + 5 volts

Pin 6 Next Object Signal

If the photocell has a screened conductor, it should be connected to the shell of the D - Type

connector and to the printer chassis at the printer end of the cable (it must not be connected to D

volts).

CAUTION: Electromagnetic Compatibility performance may be compromised by the use of

unsuitable photocells. Use only EC-JET approved accessories.

1.7 Setting up the Shaft Encoder

Shaft encoders are recommended for production lines where variable speed is likely. A shaft

encoder generates a pulse for a fixed distance of product movement. This can be used to produce

Loading...

Loading...