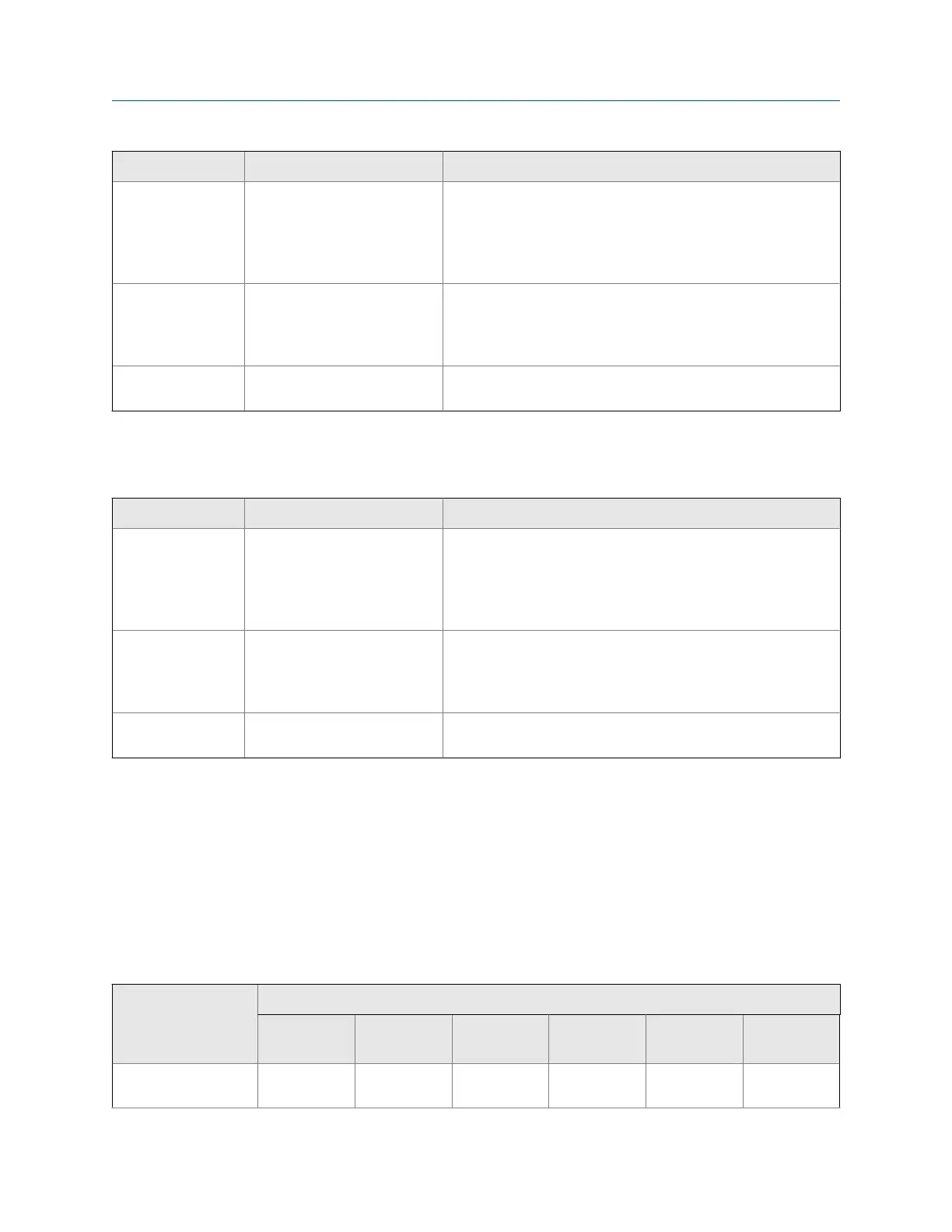

Option Description Setup

Polling The meter polls an external de-

vice for % N2 data.

a. Set % N2 Source to Poll for External Value.

b. Set Polling Slot to an available slot.

c. Set Polling Control to Poll as Primary or Poll as Secondary.

d. Set External Device Tag to the HART tag of the % N2 meas-

urement device.

Digital communica-

tions

A host writes % N2 data to the

meter at appropriate intervals.

a. Set % N2 Source to Fixed Value or Digital Communications.

b. Perform the necessary host programming and communica-

tions setup to write % N2 data to the meter at appropriate

intervals.

Fixed value The configured fixed value is

used.

a. Set % N2 Source to Fixed Value or Digital Communications.

b. Set % N2 (Fixed) to the desired value, in % by volume.

8. If you set Compressibility Measurement Method to SGERG 88, set % H2 Source to the

method you will use to supply % H2 data, and perform the required setup.

Option

Description Setup

Polling The meter polls an external de-

vice for % H2 data.

a. Set % H2 Source to Poll for External Value.

b. Set Polling Slot to an available slot.

c. Set Polling Control to Poll as Primary or Poll as Secondary.

d. Set External Device Tag to the HART tag of the % H2 meas-

urement device.

Digital communica-

tions

A host writes % H2 data to the

meter at appropriate intervals.

a. Set % H2 Source to Fixed Value or Digital Communications.

b. Perform the necessary host programming and communica-

tions setup to write % H2 data to the meter at appropriate

intervals.

Fixed value The configured fixed value is

used.

a. Set % H2 Source to Fixed Value or Digital Communications.

b. Set % H2 (Fixed) to the desired value, in % by volume.

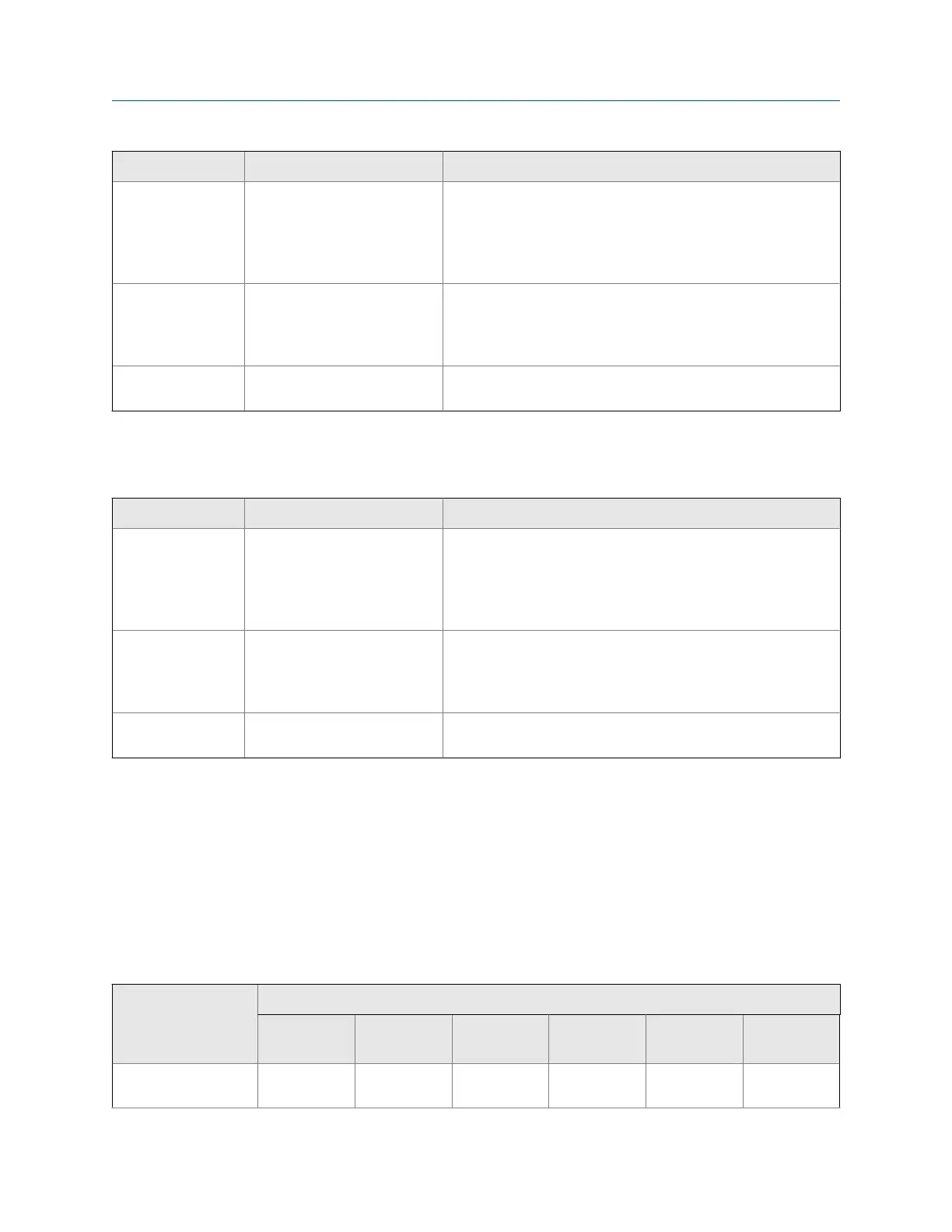

7.4.1 Compressibility Method and process limits

Each method for calculating compressibility has specific limits for line temperature, line

pressure, and other process variables. If your process goes outside the valid range,

compressibility will be reported as NaN (Not a Number). All process variables that require

compressibility will also be reported as NaN.

Specific gravity and molecular weight meters: Compressibility Method and valid ranges for

process variables

Table 8-2:

Compressibility

Method

Valid range

Temperature Pressure

Specific

gravity % CO2 % N2 % H2

AGA NX-19

−40 to

+115.556 °C

1.01325 to

345.751 BarA

0.55 to 1 0–15% 0–15% 0–15%

Configure process measurement using ProLink III

60 Micro Motion

®

Gas Specific Gravity Meters (SGM)

Loading...

Loading...