Proline Promass E 300 PROFINET Technical data

Endress+Hauser 237

Supported functions • Identification & Maintenance

Simple device identification via:

• Control system

• Nameplate

• Measured value status

The process variables are communicated with a measured value status

• Blinking feature via the onsite display for simple device identification and

assignment

• Device operation via operating tools (e.g. FieldCare, DeviceCare, SIMATIC

PDM)

System integration Information on system integration → 76.

• Cyclic data transmission

• Overview and description of the modules

• Status coding

• Startup configuration

• Factory setting

16.5 Power supply

Terminal assignment → 33

Device plugs available → 33

Pin assignment, device plug → 33

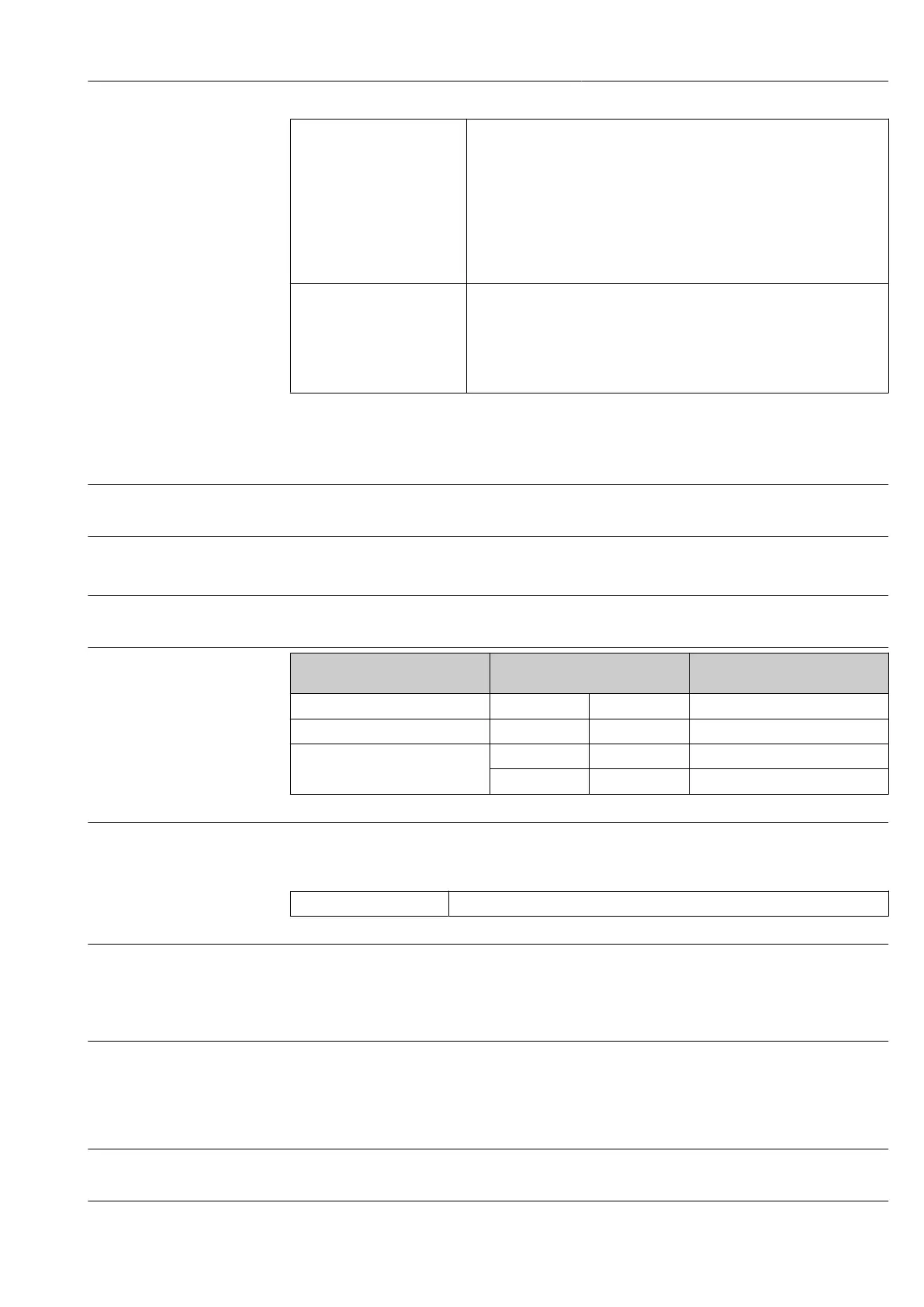

Supply voltage

Order code for

"Power supply"

Terminal voltage Frequency range

Option D DC 24 V ±20% –

Option E AC 100 to 240 V –15 to +10% 50/60 Hz

Option I

DC 24 V ±20% –

AC 100 to 240 V –15 to +10% 50/60 Hz

Power consumption Transmitter

Max. 10 W (active power)

switch-on current Max. 36 A (<5 ms) as per NAMUR Recommendation NE 21

Current consumption Transmitter

• Max. 400 mA (24 V)

• Max. 200 mA (110 V, 50/60 Hz; 230 V, 50/60 Hz)

Power supply failure • Totalizers stop at the last value measured.

• Depending on the device version, the configuration is retained in the device memoryor in

the pluggable data memory (HistoROM DAT).

• Error messages (incl. total operated hours) are stored.

Electrical connection → 34

Potential equalization → 40

Loading...

Loading...