Enertech Global, LLC 22

AV : MD/ME - Rev. A Models

Installaon and Operaons Manual

Successful design of the system must also include pipe

diameter and layout. The following guidelines should be

considered for all hydronic designs:

• Proper Flow Rate: There could be two dierent ow rates

on each side of the Indoor Module, depending upon the

size and number of zones and the size of the heat pump.

Supply/return lines for the heat pump side of the Indoor

Module must be sized for the heat pump ow rate;

supply/return lines on the system pump side of the Indoor

Module must be sized based upon the number and size of

connected zones.

• Supply/Return Pipe Diameter: Any hydronic system with

parallel piping to various zones requires large enough

piping diameter to provide sucient ow to all zone, but

also to assist in purging air from the system. The ow rate

though the supply/return lines must be high enough to

achieve 2 feet per second velocity in all of the parallel

branches. “Home Run” style piping, as menoned above,

is helpful in purging air, as well.

• Low Pressure Drop: Selecng Pipe diameter for supply/

return lines will help ensure low pressure drop and good

performance.

Enertech recommends “Home Run” style piping to help

facilitate air removal, but also for ease of access to the zone

valves. In the “Branch” style piping, branches can be dicult

to purge, depending upon the size of the supply/return lines

feeding the branches, especially if fan coils are piped in this

manner.

Note: Purging air from the system is one of biggest

challenges for hydronic systems. Flow Sensors installed in

this equipment are extremely sensive to micro-bubbles.

Example

System includes a model 060 heat pump with one 3 ton fan

coil and 3 radiant zones. Two radiant zones each have 5

circuits and one radiant zone has 3 circuits (13 total circuits).

All circuits are 1/2” PEX piping.

The radiant heang calculaons determined that the PEX

loops will be at 9” O.C. spacing and that the ow rate per

circuit will be 0.42 GPM (5.5 GPM total). The system will use

25% Fernox Alphi-11 propylene glycol anfreeze. The

following steps should be used to determine pipe sizing:

1. Determine ow rate and pipe diameter for piping from

Indoor Module to the “Home Run” hydronic zones. The

fan coil needs 9 GPM, and the 1/2” radiant tubing could

be up to 0.75 GPM per circuit, but since 0.42 GPM was

specied, the applicaon will use the specied ow rate

(13 x 0.42 = 5.5 GPM). Total ow rate is 14.5 GPM (9 +

5.5). The supply/return lines from the Indoor Module to

the zones should be 1-1/4” copper or 1-1/2” PEX.

2. Similar calculaons should be done for each zone. For the

fan coil zone (9 GPM), 1” copper or 1-1/4” PEX should be

run to the fan coil; for the 5 circuit manifold, 3/4” PEX

may be used (same for the 3 circuit manifold).

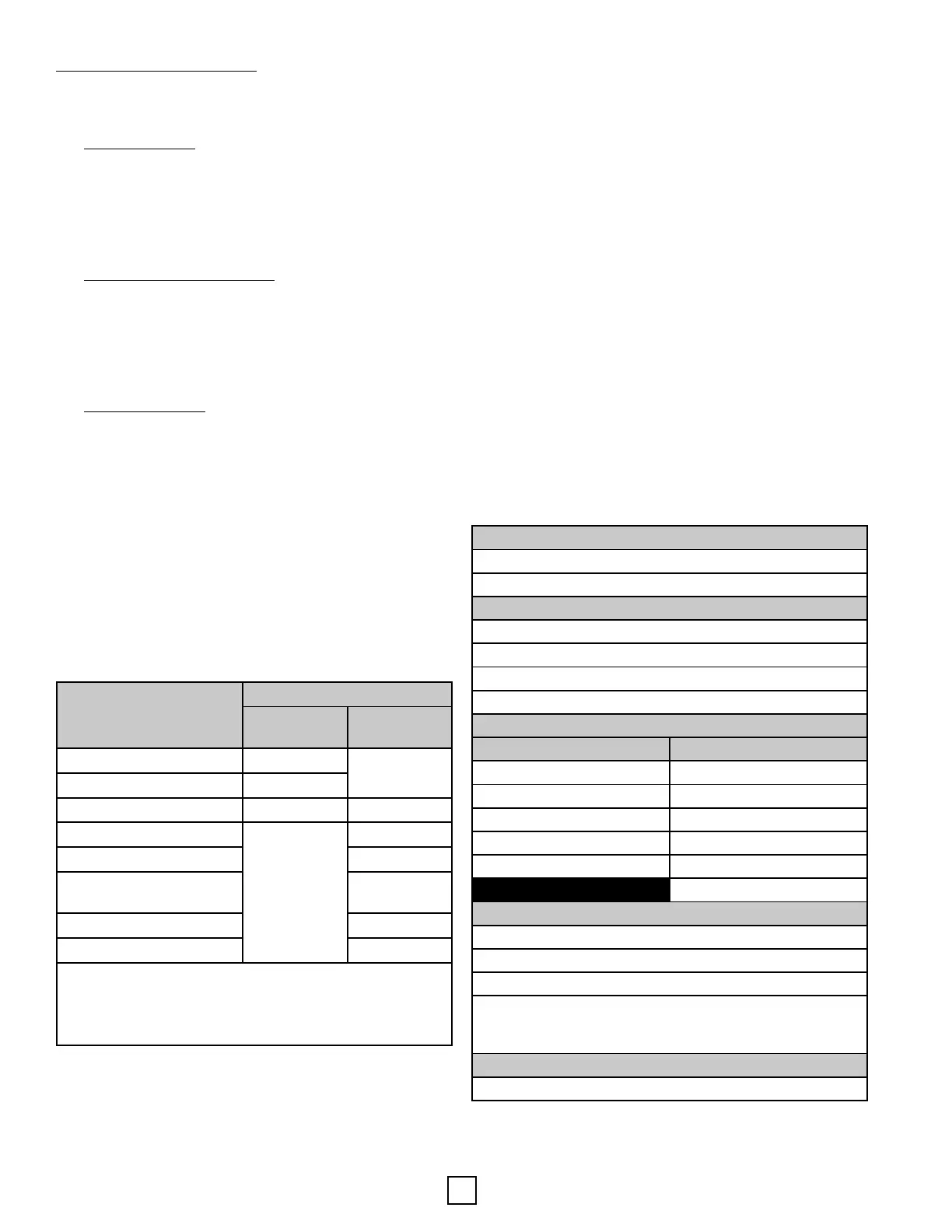

Recommended Flow Rates

Heat Pump

EAV040 – 12 GPM

EAV060 – 15 GPM

MPH Fan Coils/Air Handlers & ACH/MCH A-Coils

MPH/ACH/MCH024 – 6 GPM

MPH/ACH/MCH036 – 9 GPM

MPH/ACH/MCH048 – 13 GPM

MPH/ACH/MCH060 – 13 GPM

Mul-Aqua Fan Coils

High-wall units Console Units

MHQWW-9 – 3 GPM CFFWA-3 – 3 GPM

MHQWW-12 – 6 GPM CFFWA-6 – 4.5 GPM

MHQWW-18 – 6 GPM CFFWA-8 – 5.5 GPM

MHQWW-24 – 7 GPM CFFWA-12 – 8 GPM

MHQWW-36 – 10 GPM CFFWA-16 – 10.5 GPM

CFFWA-20 – 12.5 GPM

Radiant Floor

1/2" PEX – 0.5 to 0.75 GPM per circuit

5/8" PEX – 0.75 to 1 GPM per circuit

3/4" PEX - 1 to 1.25 GPM per circuit

Example: A 5 loop manifold with 1/2” PEX circuits would

need supply/return piping capable of supplying 2.5 to 3.75

GPM

DHW Piping

Use ow rate for heat pump

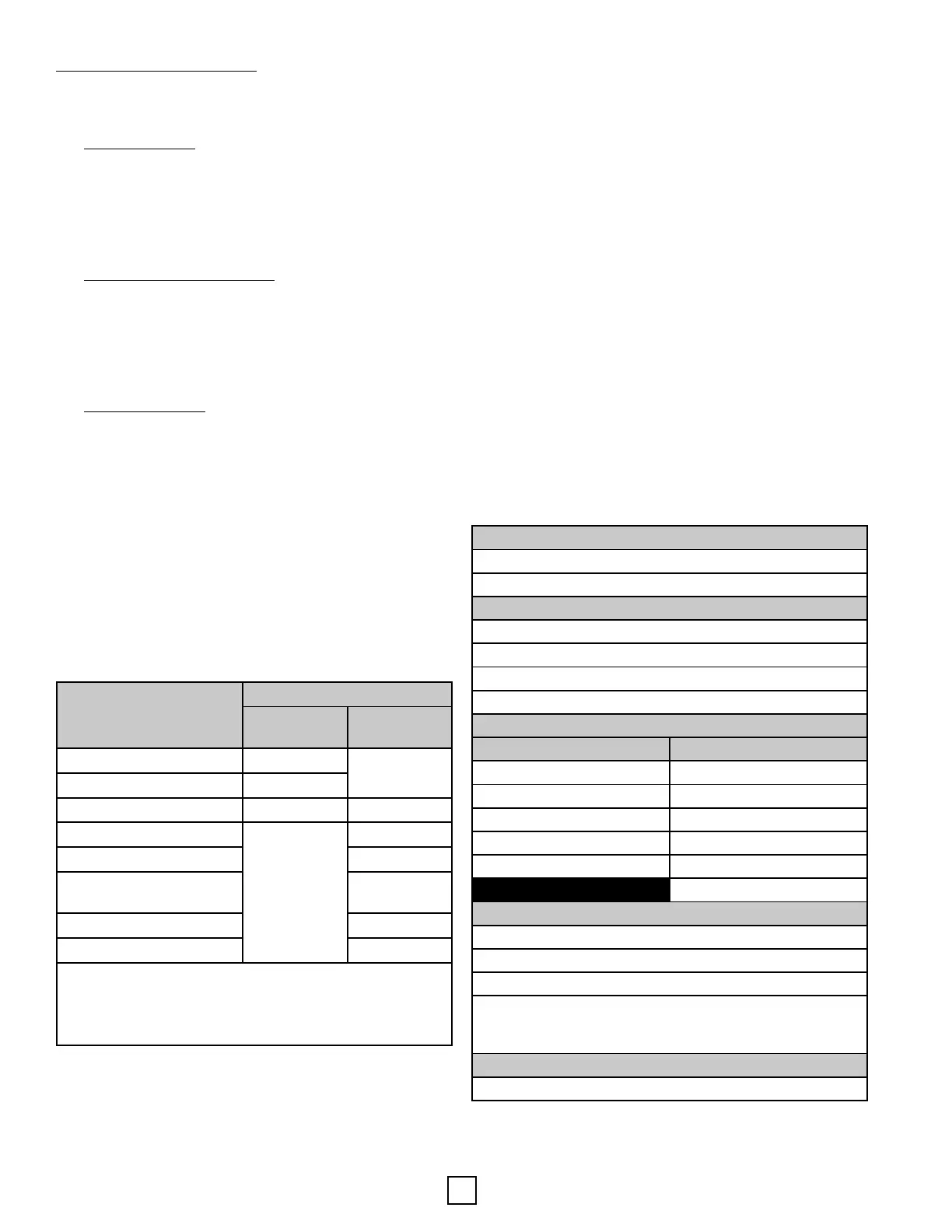

Pipe Diameter/Type

Maximum Flow Rate (GPM)

Floor Loop*

Supply/Re-

turn**

1/2” PEX 0.75

N/A

5/8” PEX 1

3/4” PEX 1.25 4

3/4” Copper or 1” PEX

N/A

7

1” Copper or 1-1/4” PEX 12

1-1/4” Copper or 1-1/2”

PEX

17

1-1/2” Copper 25

2” Copper 45

* Based upon 300 . circuits.

**Based upon 25. length (one-way) and 4 elbows

with water. When using anfreeze, increase pipe size

to the next size if close to the maximum ow rate.

Secon 5: Unit Piping

Loading...

Loading...