Enertech Global, LLC 34

AV : MD/ME - Rev. A Models

Installaon and Operaons Manual

If the unit will be used for cooling, anfreeze must be added

on the load side of the system to protect the braze plate heat

exchanger from rupturing. Chilled soluon set points are in

the 40’s °F. The load soluon so within the heat exchanger,

could be near freezing. To protect against freezing. Enertech

recommends the use of Propylene Glycol (20-25%) for the

load side anfreeze. Addional inhibitor may be required if

the concentraon is less than 25% to 30% (depending upon

brand) to provide corrosion protecon and prevent bacterial

growth.

Important: Propylene glycol concentraons below 30%

typically require addional inhibitors to be added to the

soluon. Enertech recommends Fernox F1.

Note: The minimum recommended air handler size is 2 tons.

Selecon of the anfreeze soluon for closed loop systems

require the consideraon of many important factors, which

have long-term implicaons on the performance and life of

the equipment. Each area of concern leads to a dierent “best

choice” of anfreeze. There is no “perfect” anfreeze. Some

of the factors to consider are as follows (Brine = anfreeze

soluon including water):

Safety: The toxicity and ammability of the brine (especially

in a pure form).

Cost: Prices vary widely.

Thermal Performance: The heat transfer and viscosity eect

of the brine.

Corrosiveness: The brine must be compable with the

system materials.

Stability: Will the brine require periodic change out or

maintenance?

Convenience: Is the anfreeze available and easy to

transport and install?

Codes: Will the brine meet local and state/provincial codes?

The following are some general observaons about the types

of brines presently being used:

Methanol: Wood grain alcohol that is considered toxic in pure

form. It has good heat transfer, low viscosity, is non-corrosive,

and is mid to low price. The biggest down side, it is ammable

in concentraons greater than 25%.

Ethanol: Grain alcohol, which by the ATF (Alcohol, Tobacco,

Firearms) department of the U.S. government, is required to

be denatured and rendered unt to drink. It has good heat

transfer, mid to high price, is non-corrosive, non-toxic even in

its pure form, and has medium viscosity. It is also ammable

with concentraons greater than 25%. Note that the brand of

ethanol is very important. Make sure it has been formulated

for the geothermal industry. Some of the denaturants are not

compable with HDPE pipe (for example, soluons denatured

with gasoline).

Propylene Glycol: Non-toxic, non-corrosive, mid to high price,

poor heat transfer in high concentraons, and potenal for

high viscosity when cold (in high concentraons). It has also

been known to form a “slime-type” coang inside the pipe

when inhibitors are not used. Do not use food grade glycol,

since it does not include inhibitors. A 25% to 30% brine

soluon is a minimum concentraon for required inhibitors,

depending upon brand of glycol. If using a lower concentraon

(e.g. 20% provides 19°F freeze protecon), addional

inhibitors must be added. Note that some states/provinces

have toxicity requirements that must be veried based upon

the chemical composion of the inhibitors.

Ethylene Glycol: Considered toxic and is not recommended for

use in earth loop applicaons.

Calculate the total amount of pipe in the system and use the

following Pipe Fluid Volume Table to calculate the amount of

volume for each specic secon of the system. Add the enre

volume together, and mulply that volume by the proper

anfreeze percentage needed

for the freeze protecon required in your area.

Then double check calculaons during installaon with the

proper hydrometer and specic gravity chart

) to determine if the correct amount of

anfreeze was added.

⚠ WARNING ⚠

USE EXTREME CARE WHEN OPENING, POURING,

AND MIXING FLAMMABLE ANTIFREEZE SOLUTIONS.

REMOTE FLAMES OR ELECTRICAL SPARKS CAN IGNITE

UNDILUTED ANTIFREEZES AND VAPORS. USE ONLY

IN A WELL VENTILATED AREA. DO NOT SMOKE WHEN

HANDLING FLAMMABLE SOLUTIONS. FAILURE TO

OBSERVE SAFETY PRECAUTIONS MAY RESULT IN

FIRE, INJURY, OR DEATH. NEVER WORK WITH 100%

ALCOHOL SOLUTIONS.

Secon 6: Anfreeze

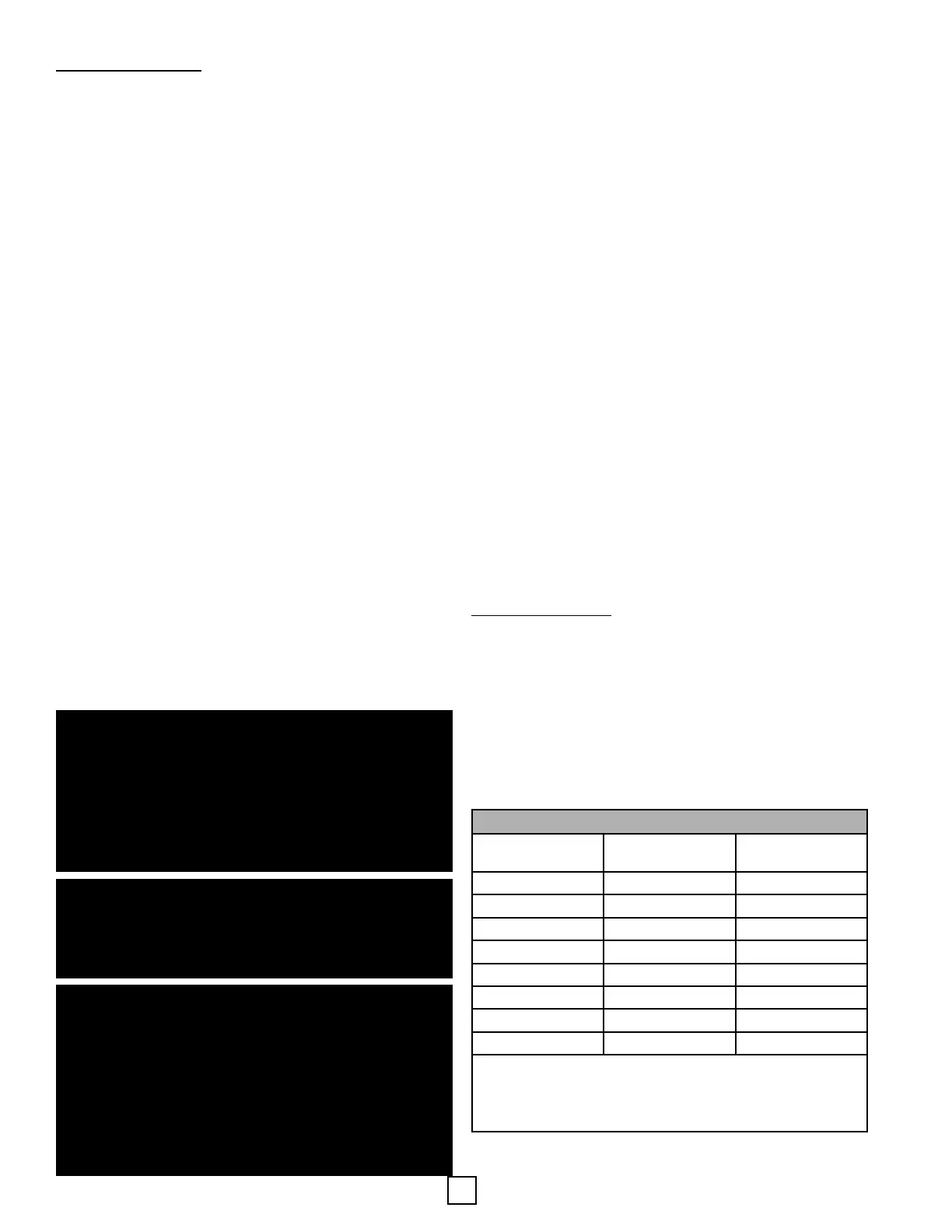

Pipe Fluid Volume Table

Type Size

Volume Per 100

US Gallons

Copper 1” CTS 4.1

Copper 1.25” CTS 6.4

Copper 1.5” CTS 9.2

HDPE .75” SDR11 3.0

HDPE 1” SDR11 4.7

HDPE 1.25” SDR11 7.5

HDPE 1.5” SDR11 9.8

HDPE 2” SDR11 15.4

Notes:

Unit coaxial heat exchanger = 1 Gallon

Flush Cart = 8-10 Gallons

10’ of 1” Rubber Hose = 0.4 Gallons

⚠ WARNING ⚠

IF MORE THAN 30% ANTIFREEZE IS ADDED, HEAT

TRANSFER AND VISCOSITY ISSUES MAY ARISE. BE

SURE TO KNOW WHAT TYPE OF ANTIFREEZE IS

⚠ CAUTION ⚠

HYDRONIC LOOPS MUST BE ANTIFREEZE PROTECTED.

INSUFFICIENT AMOUNTS OF ANTIFREEZE MAY CAUSE

SEVERE DAMAGE AND MAY VOID WARRANTY.

FLAMMABLE. NEVER OPERATE WITH HYDRONIC LOOP

FLOW RATES LESS THAN SPECIFIED. CONTINUOUS

OPERATION AT LOW FLOW OR NO FLOW MAY CAUSE

SEVERE DAMAGE AND MAY VOID WARRANTY.

Loading...

Loading...