Enertech Global, LLC 55

AV : MD/ME - Rev. A Models

Installaon and Operaons Manual

• Check that the pipe system is complete.

• Check the pipe system for leaks.

• Check that the electrical installaon is prepared.

• Check that the electrical supply is connected so that the

compressor crankcase heater can start warming up the

compressor, if necessary.

• The compressor crankcase heater must have been acve

for at least 3 hours before compressor operaon can be

iniated. This is done by connecng control voltage. EAV

permits compressor start aer the compressor has been

warmed up. This can take up to 3 hours.

1. Fill the hydronic system to the necessary pressure.

2. Vent the system using the venng port on the ex tube

(included) and possibly the circulaon pump.

3. See “Flushing and Filling System” for details.

1. Communicaon cable, the EAV terminal block (X22:1-4)

must be connected.

2. Turn the isolator switch on.

3. Ensure that the EAV is connected to the power source.

4. Reinstall the removed panels and cover.

5. Aer the power to EAV has been switched on and there

is a compressor demand from the indoor module/control

module, the compressor starts once it has warmed up,

aer max 180 minutes. The length of this me delay

depends on whether the compressor has been warmed

up previously. See chapter Preparaons secon, above.

Preparing Piping System

Air is inially released from the water/anfreeze soluon and

venng may be necessary. If bubbling sounds can be heard

from the heat pump, the circulaon pump and piping/fan coils

the enre system will require further ushing/purging. When

the system is stable (correct pressure and all air eliminated)

the control system can be set as required.

General

EAV is equipped with an internal electronic controller that

handles all funcons necessary for operaon of the heat

pump, e.g. defrost cycle, stop at max/min. temperature,

connecon of the compressor heater, and protecve funcons

during operaon. Temperatures, number of starts and run

me, are displayed in the indoor module/control module.

The integrated control shows informaon via status-LEDs and

can be used during servicing.

Under normal operang condions the home owner does not

need to have access to the controller.

EAV communicates with the Enertech indoor module/control

module, which means that all sengs and measurement

values from EAV are adjusted and displayed on the indoor

module/control module.

Please wait.

Internal valve in Hot Water

Tank position.

3.10.1.2 3.10.1.3 3.10.1.4 3.10.1.5

3.10.1.6 3.10.1.7 3.10.1.8 3.10.1.9

3.10.1.10

3.9.0.3 3.9.1 3.10.0.1 Startup Wizard Button

3.10.1.1a

3.10.0.2 Startup Wizard Idle Prompt 3.10.1.1

This will take you back to

the startup wizard

Flush Outdoor Unit

Flush Outdoor Unit

heat exchanger and piping

between the Indoor/

Outdoor units until air is

removed.

Please open ALL zone

valves and press NEXT.

Please wait.

Internal valve in hydronic

position.

Completely flush every

circuit until it is void of all air.

Please open ALL zone

valves and press NEXT.

House zones test in

progress. Please wait:

5 min

House zones test in

progress. Please wait:

5 min

Step 1 Step 2 Step 3

The Startup Wizard is part of the First Run Setup. This Wizard

is designed to ensure that the system has the proper ow

rates and that air is purged from this system. Screens from the

Startup Wizard are shown on the following pages.

Secon 9: Equipment Start-Up

6. Adjust menu sengs via the indoor HMI (touchscreen

Human Machine Interface) as necessary.

7. Fill in the commissioning report.

8. Remove the protecve lm from the cover on EAV.

3.6.0 3.6.1 Hot Water Setpoint 3.6.2 Hot Water Deadband

3.7.2 Load Pump Max Speed 3.7.3 Delta Temp Heat Setpoint 3.7.4 Deta Temp Cool Setpoint

3.8.1 Pressure Units 3.8.2 Replace Filter 3.9.0

3.7.0 3.7.1 Load Pump Min Speed

3.7.5 Temp Units 3.8.0

3.9.0.1 3.9.0.2

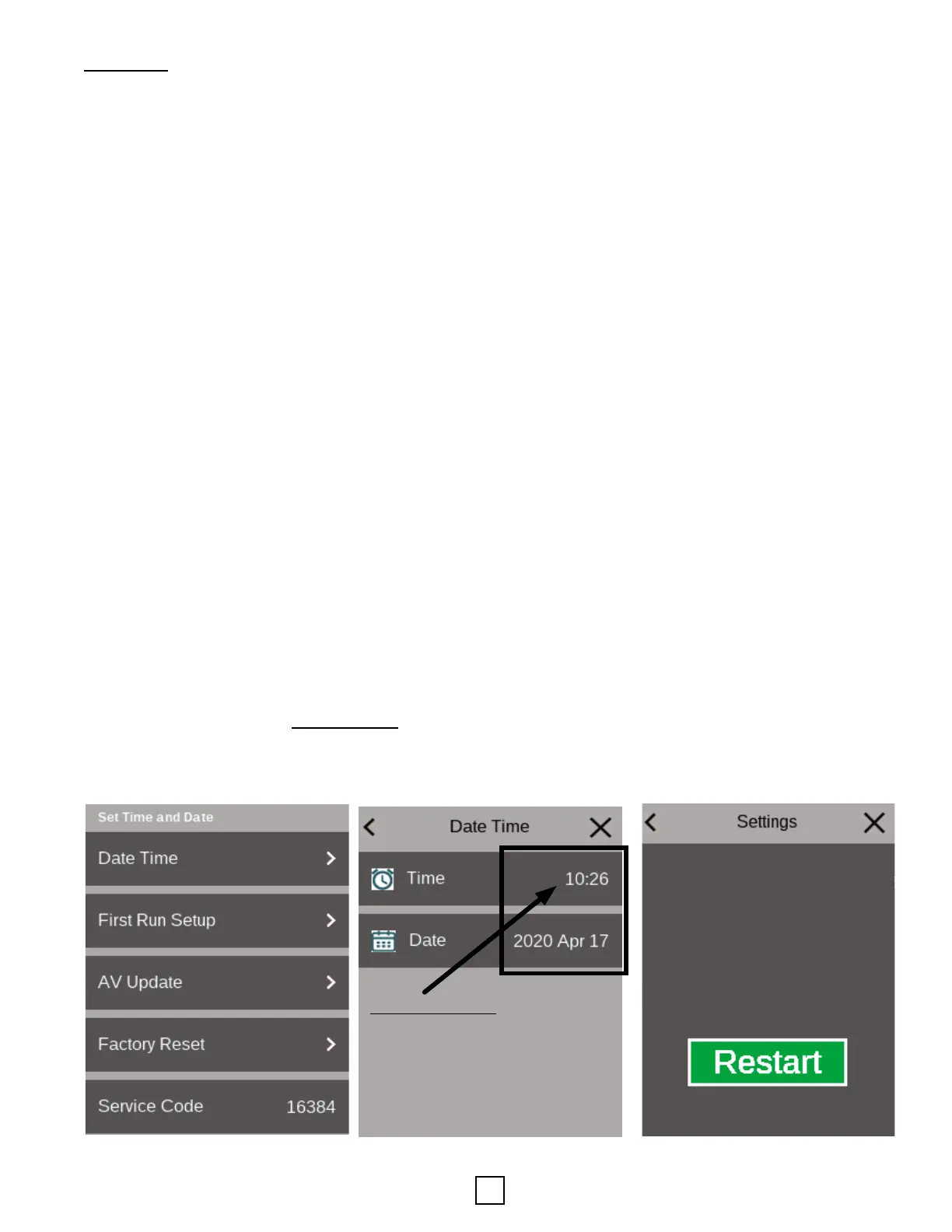

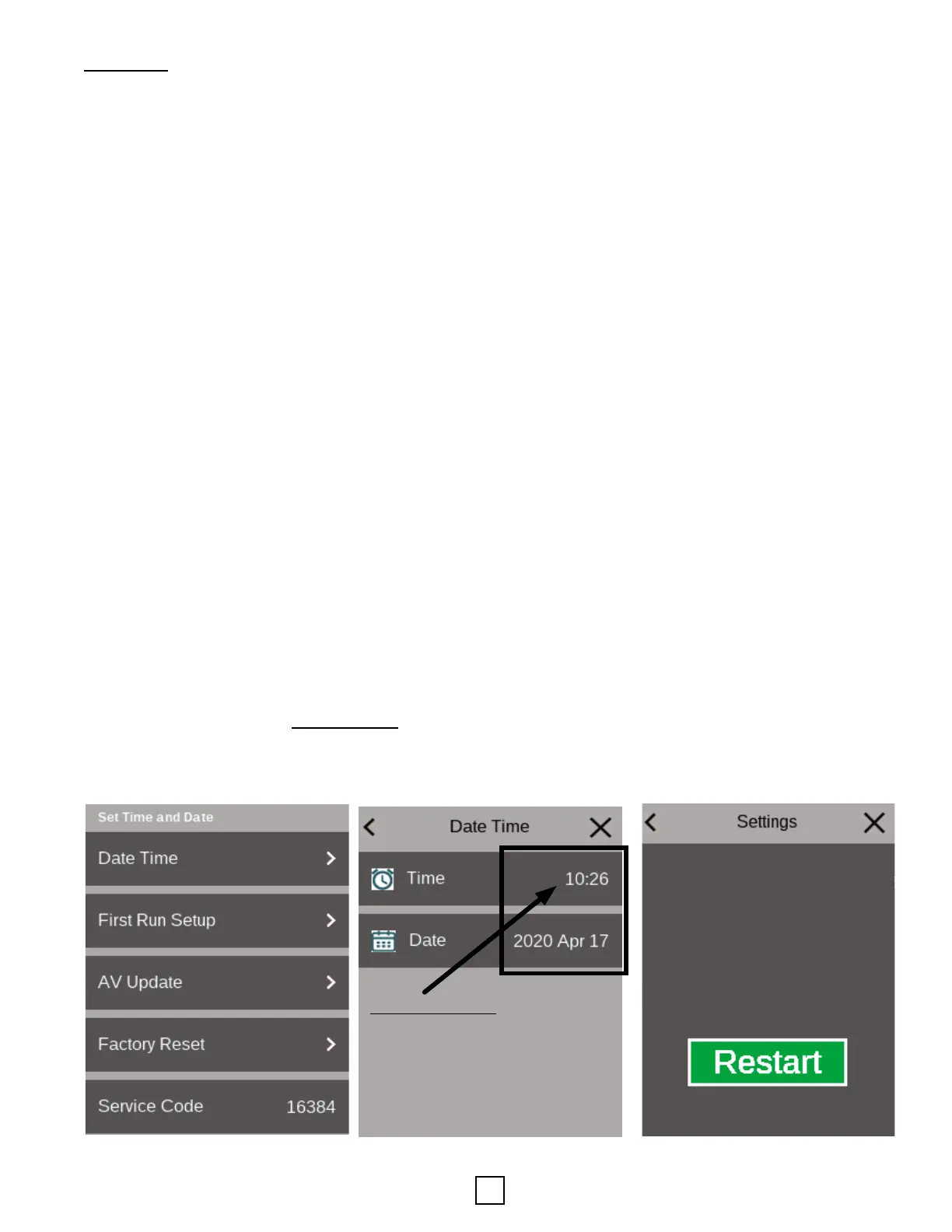

*MILITARY TIME*

Loading...

Loading...