Enertech Global, LLC 26

AV : MD/ME - Rev. A Models

Installaon and Operaons Manual

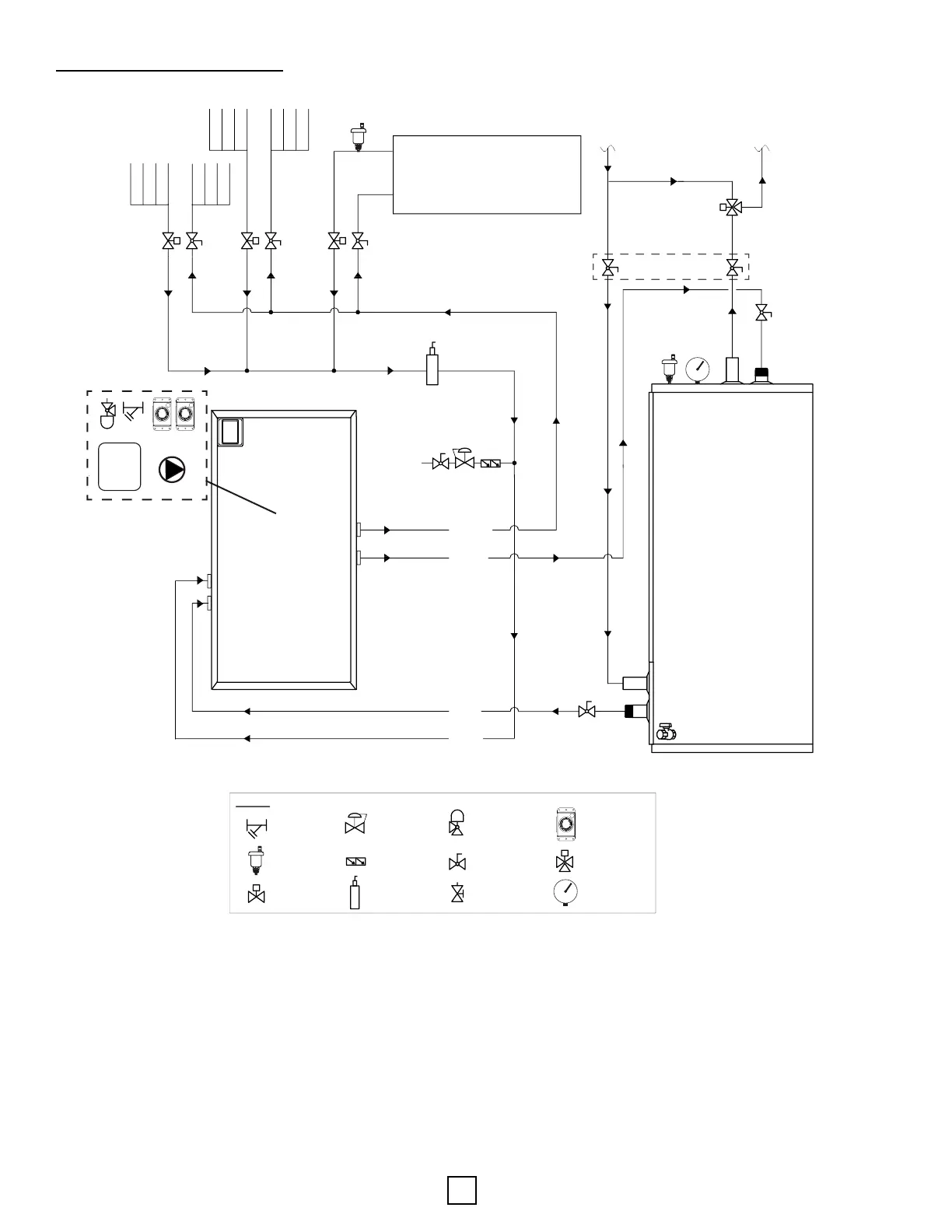

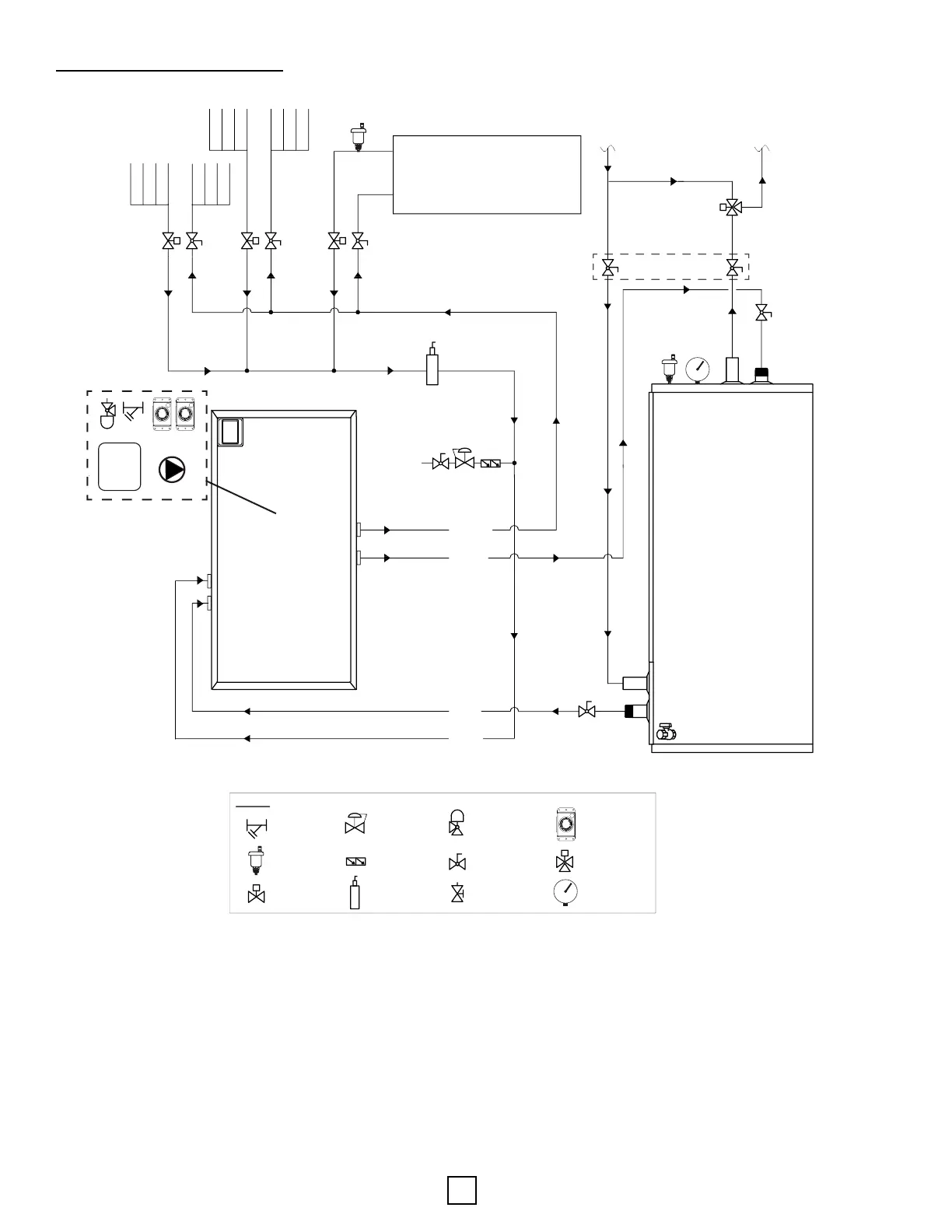

Secon 5: Unit Piping

Piping Diagram - Indoor Module

DHW OUT

LOAD OUT

NOTE 5

NOTE 5

DOMESTIC

HOT

WATER

DOMESTIC

COLD

WATER

HOT

COLD

LOAD

IN

LOAD

OUT

AUTOMATIC

AIR VENT

3-WAY FLUSH

VALVE

ANTI-SCALD OR

MIXING VALVE

PRESSURE

GAUGE

ΔP

LEGEND

WYE STRAINER

ACTUATED

ZONE VALVE

PRESSURE

REDUCING VLV

BACK-FLOW

PREVENTER

AIR SEPARATOR

DIF. PRESSURE

BYPASS VALVE

ISOLATION BALL

VALVE

BOILER DRAIN

NOTE 5

ΔP

Expan.

Tank

INDOOR UNIT

LOAD IN

DHW IN

FACTORY INSTALLED

INTERNAL TO UNIT

TURBOMAX 65

WATER HEATER

FOR TYPICAL

RESIDENTIAL

APPLICATIONS

(FOR LARGER DOMESTIC

HOT WATER NEEDS SEE

DHW SECTION IN IOM)

NOTE 5

MAKE-UP WATER OR

GLYCOL FEEDER

NOTE 6

RADIANT

FLOOR

HEATING

ZONE 2

RADIANT

FLOOR

HEATING

ZONE 3

NOTE 4

NOTE 5 NOTE 5

NOTE 6

HYDRONIC AIR HANDLER

OR PANEL RADIATOR

ZONE 1

NOTE 5

NOTES:

1. INSTALLATION DIAGRAM SHOWN ABOVE IS AN EXAMPLE OF A TYPICAL (RECOMMENDED) INSTALL. ADDITIONAL ZONES ARE

ALLOWED, AS WELL AS ALERNATE PIPING LAYOUTS.

2. UNIT CONFIGURATION INCLUDES INDIRECT DHW TANK.

3. A HOSE KIT HAS BEEN PROVIDED WITH THE UNIT AND SHOLD BE INSTALLED AT THE OUTDOOR UNIT.

4. ALL PIPING MUST BE “HOME RUN” STYLE. ALL RADIANT MANIFOLDS AND AIR HANDLER UNIT ZONE VALVES SHOULD BE LOCATED

IN THE MECHANICAL ROOM TO FACILITATE FLUSHING/PURGING OF AIR FROM SYSTEM.

5. FIELD PROVIDED FOR FUTURE SERVICE

6. MOUNT AT THE HIGHEST POINT ON THE RETURN LINE.

7. ALWAYS CHECK LOCAL CODE REQUIREMENTS TO ENSURE THAT THE INSTALLATION MEETS CURRENT REGULATORY STANDARDS.

Loading...

Loading...