Enertech Global, LLC 29

AV : MD/ME - Rev. A Models

Installaon and Operaons Manual

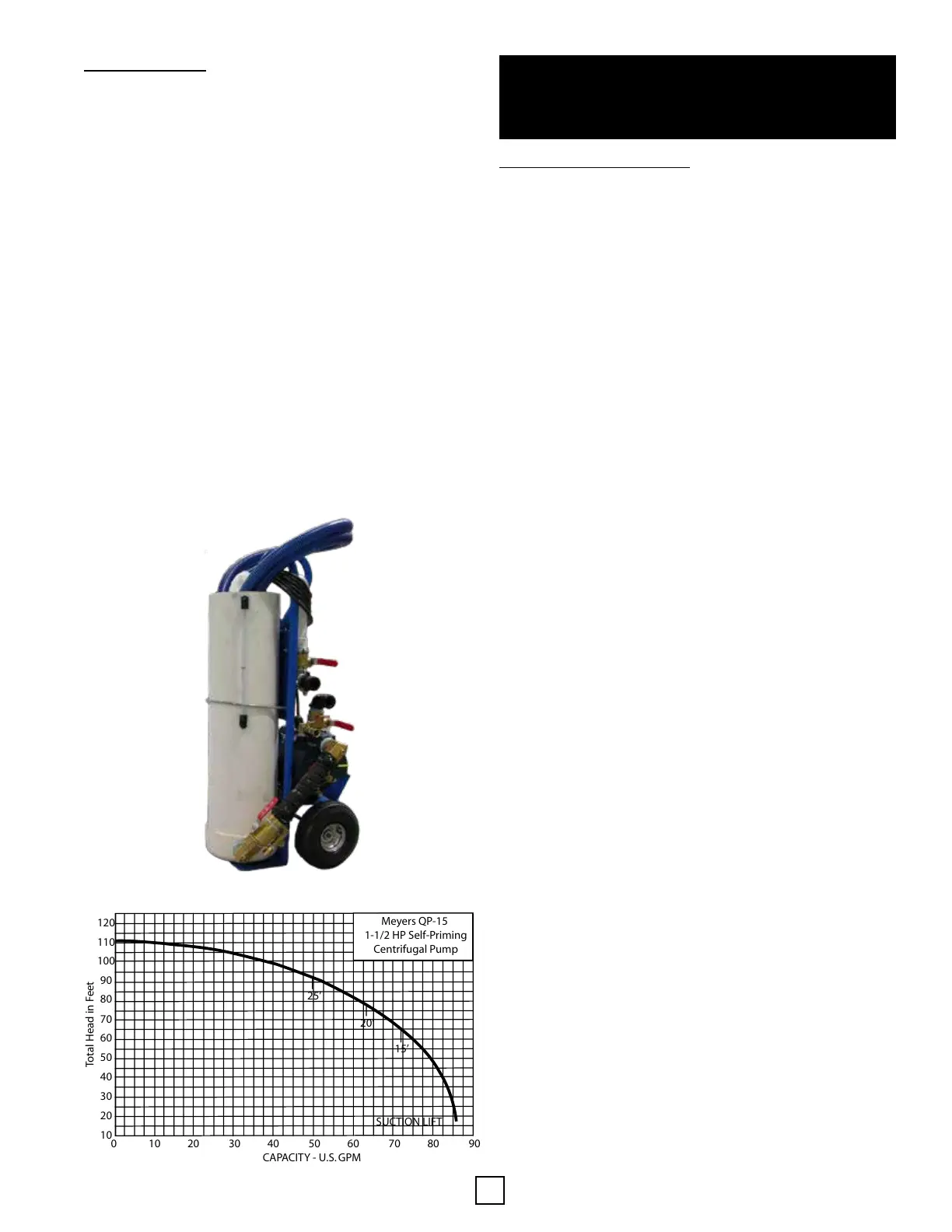

Flush Cart Design

The Enertech Manufacturing ush cart has been designed to

eecvely and eciently ush the earth loop and to facilitate

injecng and mixing of the anfreeze.

Removing Debris During Flushing

Most ow center or pump failures are a result of poor water

quality or debris. Debris entering the loop during fusion and

installaon can cause noise and premature pump failure.

Enertech recommends a double ush ltering method during

purging. When purging, use a 100 micron bag lter unl air

bubbles are removed. Remove the 100 micron bag, replace it

with a 1 micron bag and restart the ushing.

• Cylinder: HDPE, SDR15.5, 10” dia. (10 Gallons)

• Pump: Myers High Head QP15, 1.5hp, 115V

• Hose connecons: Cam Lock quick connects - 1-1/2”

hoses

• Hand Truck: 600lb rang with pneumac res

• Wiring: Liquid Tight metal on/o switch

• Tubing: SDR11 HDPE

• Connecons: 2 - 3/4” connecons for anfreeze and

discharge

• Drain: one on the pump and the tank

0 10 20 30 40 50 60 70 80 90

CAPACITY - U.S. GPM

120

110

100

90

80

70

60

50

40

30

20

10

Total Head in Feet

SUCTION LIFT

25’

20’

15’

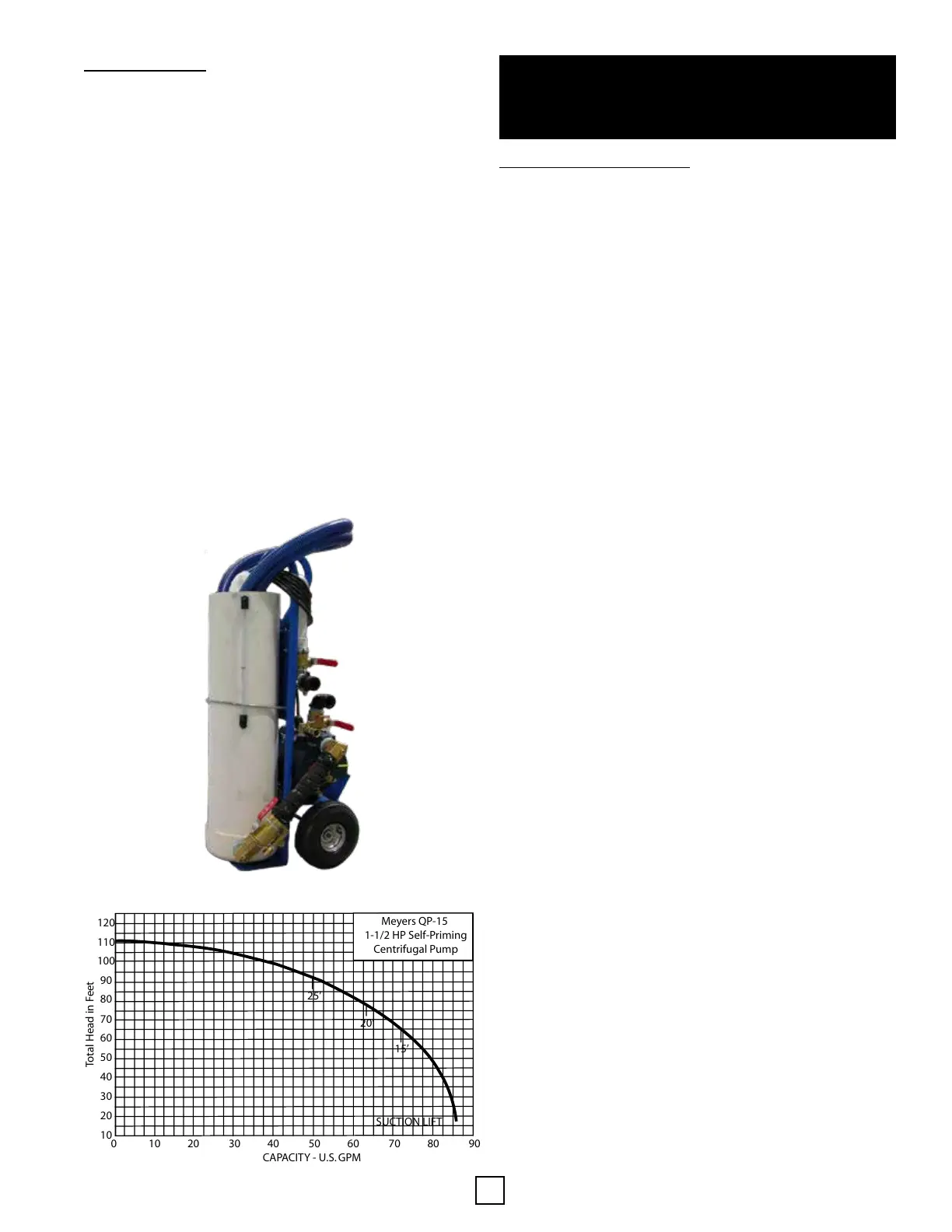

Meyers QP-15

1-1/2 HP Self-Priming

Centrifugal Pump

Flush Cart Pump Curve:

Enertech Flush Cart:

Flushing and Filling System

The system needs to be ushed of air and debris, and lled

before it is turned on and put into service. All systems have

dirt and debris from the piping, soldering, etc. Enertech

recommends using a ush cart to the purge the system. The

ush cart should ulize a ½ HP pump, which is sucient for

almost all residenal hydronic systems, as long as each circuit

is isolated and ushed one at a me.

1. Isolate each circuit, including the heat pump and domesc

hot water tank.

2. Flush each zone of air, and ll each zone with water

(radiant tubing, air handler, etc.).

This step can be skipped if the unit is not equipped with hot

water capability.

1. Open the isolaon valves and ush/ ll the hot water tank

(if equipped), making sure to keep the system pressure

below 30 PSI.

Note: If the pressure gets above 30 PSI, the relief valve on

the tank will purge water.

2. Close the isolaons valves

Step 3: Heat Pump

1. Open the isolaon valves and ush/ ll the heat pump,

making sure that the water ow direcon is as it would be

in normal operaon.

Note: Water ow direcon is crucial during this step. If the

water ow is backwards, the Wye Strainer is not protecng

the braze plate heat exchangers from the miscellaneous

debris that hasn’t been ushed out into the ush cart.

2. Once the enre system has been ushed and lled, the

anfreeze and water treatment can be added, using the

ush cart to add and mix the treatment. All zones should

be open during this process, so that proper mixing can

take place.

3. Take mulple readings, and check the anfreeze

percentage, as the system is being mixed.

4. The nal step is to go through the set up wizard on the

controller (HMI) to energize the diverng valve (if

equipped) and verify that the last bit of air is removed

from the system.

5. Turn the 3-way valves on the ush valves back to the

normal operaon mode, which closes the ush port

connecons.

6. Open the ball valves on the ush cart to relieve pressure on

the hoses. Disconnect the hoses from the ush valves.

Note: If any small amount of air is sll in the system, the air

eliminaon device will remove it and the make-up water, as

well as the expansion tank, will keep pressure on the system.

Recommended pressure seng is 12-17 PSI cold = 15-19 PSI

hot.

The enre system is now ushed, lled, treated, and ready to

be put into operaon.

⚠ WARNING ⚠

MAKE SURE TO ISOLATE THE DOMESTIC WATER TANK

BECAUSE THE RELIEF VALVE INSTALLED IN THE TANK

WILL PURGE WATER AS THE SYSTEM IS FLUSHED.

Secon 5: Unit Piping

Loading...

Loading...