Enertech Global, LLC 23

AV : MD/ME - Rev. A Models

Installaon and Operaons Manual

It is important that the load side piping of the EAV system is

sized properly for the required ow rates and is ushed and

lled with good quality water and treatment. This will help

ensure that the longevity of the pump(s), braze plates, and

other load side components.

Piping Arrangement and Components

The Wye Strainer, which contains a #40 mesh, will collect

debris le in the piping aer the system has been ushed and

lled.

Per the installaon diagrams, boiler drains and isolaon valves

need to be integrated into the load piping for proper ushing

of the system at start up, as well as for future service. Full

port isolaon valves should be used in order to ensure low

pressure drop throughout the system.

Generally, the recommended load side piping arrangement

is designed as a parallel direct return system. Each zone is in

parallel and returns directly to the heat pump. Zone valves

should be ulized on each circuit to control the soluon ow

to each manifold/zone/circuit or distribuon device. Enertech

recommends zone valves have a CV rang of 8.9 or higher to

help guarantee proper ow and low pressure drop throughout

the system. All zone valves must be on/o style valves.

Note: If it is determined that any of the zone’s ow rates

are less than 5 GPM, a pressure dierenal bypass valve is

required for proper unit operaon (Enertech P/N: ADBV4A).

CAUTION

THIS SYSTEM UTILIZES A PRESSURIZED LOAD CIRCUIT. PLEASE ENSURE THE FOLLOWING:

1. The load side piping is flushed completely and purged of air (see Secon 6, Figures 7a to 7j).

2. The differenal bypass valve is installed, and in the correct orientaon (see page 16 and

drawing below).

3. The minimum pump speed is set to allow 5 GPM through the bypass valve

with all zones closed (see page 16) if hydraulic separator or buffer tank is not

used (a hydraulic separator or buffer tank is recommended).

NOTICE: A flush cart is required for purging air from the load side piping. See WV I.O.M.,

Figures 6a to 6c for valve arrangement and Secon 6 (Flushing and Filling) for flushing steps.

Remove this page from the manual before providing to building owner.

3. The minimum pump speed is set to allow 5 GPM through the bypass valve

with all zones closed (see page 16) if hydraulic separator or buffer tank is not

used (a hydraulic separator or buffer tank is recommended).

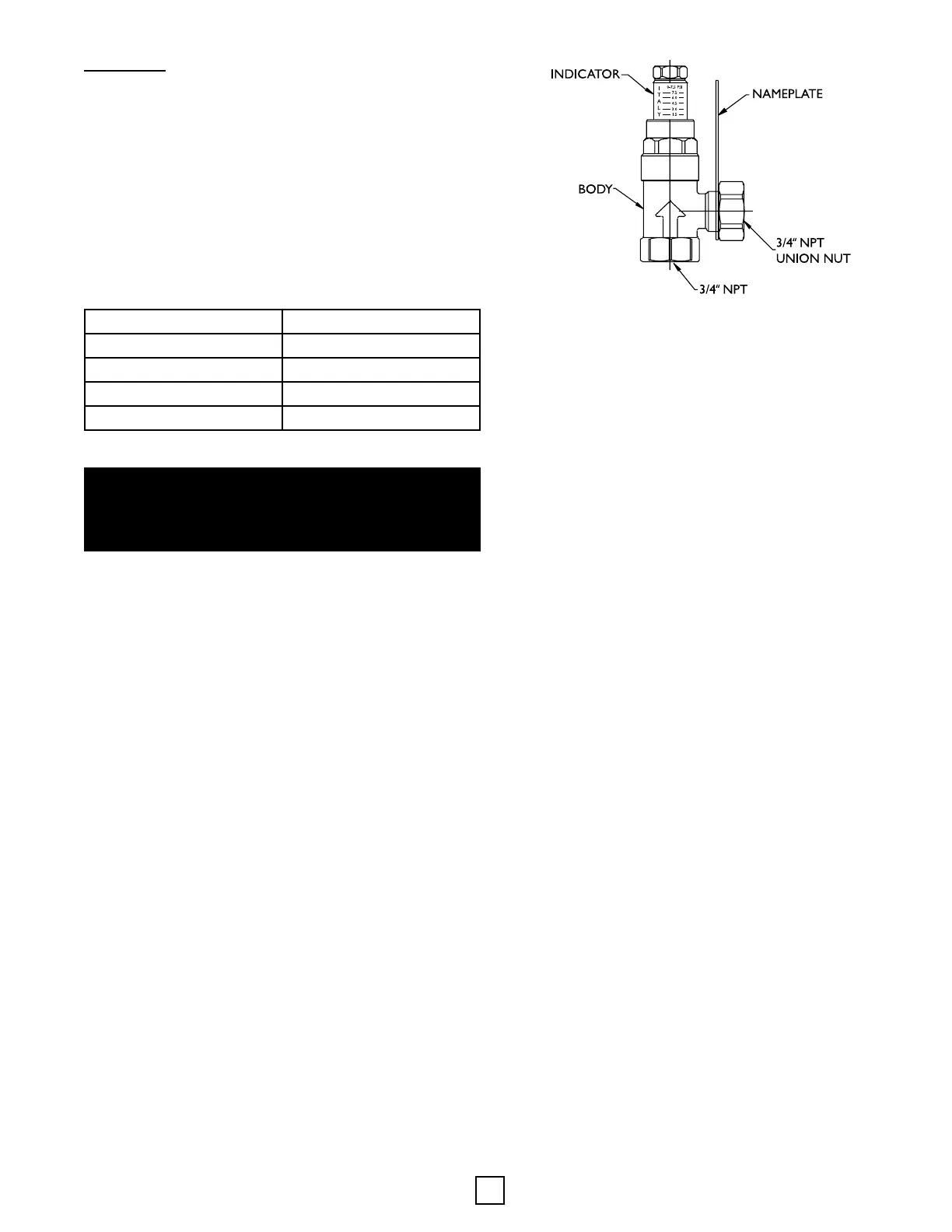

Bypass Valve

Follow the steps below for valve sengs.

1. The bypass valve seng should be adjusted during the

Startup Wizard when seng the minimum pump speed

(manual mode).

2. Set the adjustment indicator at 4.5 on the bypass valve.

3. In the Startup Wizard, start with the default minimum

pump speed at 60%. Open the zone valve for the smallest

zone (lowest ow rate). It will be important to know the

design ow rate for the smallest zone. For example, if the

smallest zone has 5 - 1/2” PEX circuits, the design ow

rate is typically 2.5 to 4 GPM. The combinaon of the

minimum pump speed and the bypass should provide a

minimum for 5 GPM.

4. Turn the adjustment indicator counter-clockwise to allow

the combined ow of the smallest zone and the bypass

valve to equal 5 GPM. The minimum pump speed may

need to be adjusted to higher than 60%, depending upon

the size of the zone.

Other Hydronic Components

An automac air eliminaon device and expansion tank are

factory installed in the indoor unit. They help remove any

micro-bubbles sll remaining aer purging and lling. The

expansion tank maintains minimum pressure in the hydronic

system for proper pump operaon.

Most local codes require certain components be installed

within the system. Local codes should be followed when

determining the exact requirements. A pressure relief valve

may be required, which should be rated for 30 PSI and

terminated 6” from the oor surface. Addionally, back-ow

preventer may be required and should be installed if a make-

up water line is connected from the water source to the load

side piping of the system.

Note: Even if a back-ow preventer is not required, it is

highly recommended.

⚠ NOTICE ⚠

THE EAV MONITORS FEEDBACK FROM THE CONNECTED

VARIABLE SPEED PUMP AND WILL NOT OPERATE

WITHOUT IT. A FLOW FAULT WILL OCCUR.

Load Piping

All interior piping must be sized for proper ow rates and

pressure loss. Insulaon should be used on all inside piping

when minimum temperatures are expected to be below

the dew point (less than approximately 50°F). Use the table

below for insulaon sizes with dierent pipe sizes. All pipe

insulaon should be made of closed cell and have a minimum

wall thickness of 3/8” for interior piping. Piping between the

Outdoor Unit and the Indoor Module should be at least 3/4”

wall thickness. All piping insulaon should be glued and sealed

to prevent condensaon and dripping. Interior piping may

consist of the following materials: PEX, copper, or stainless

steel hose (hose kit only). PVC and other piping types are not

recommended.

Secon 5: Unit Piping

Piping Material Insulaon Descripon

1” IPS Hose 1-3/8” ID - 3/8” Wall

1” IPS PE 1-1/4” ID - 3/8” Wall

1-1/4” IPS PE 1-5/8” ID - 3/8” Wall

2” IPS PD 2-1/8” ID - 3/8” Wall

Loading...

Loading...