Section 10: Material Engraving Techniques

107

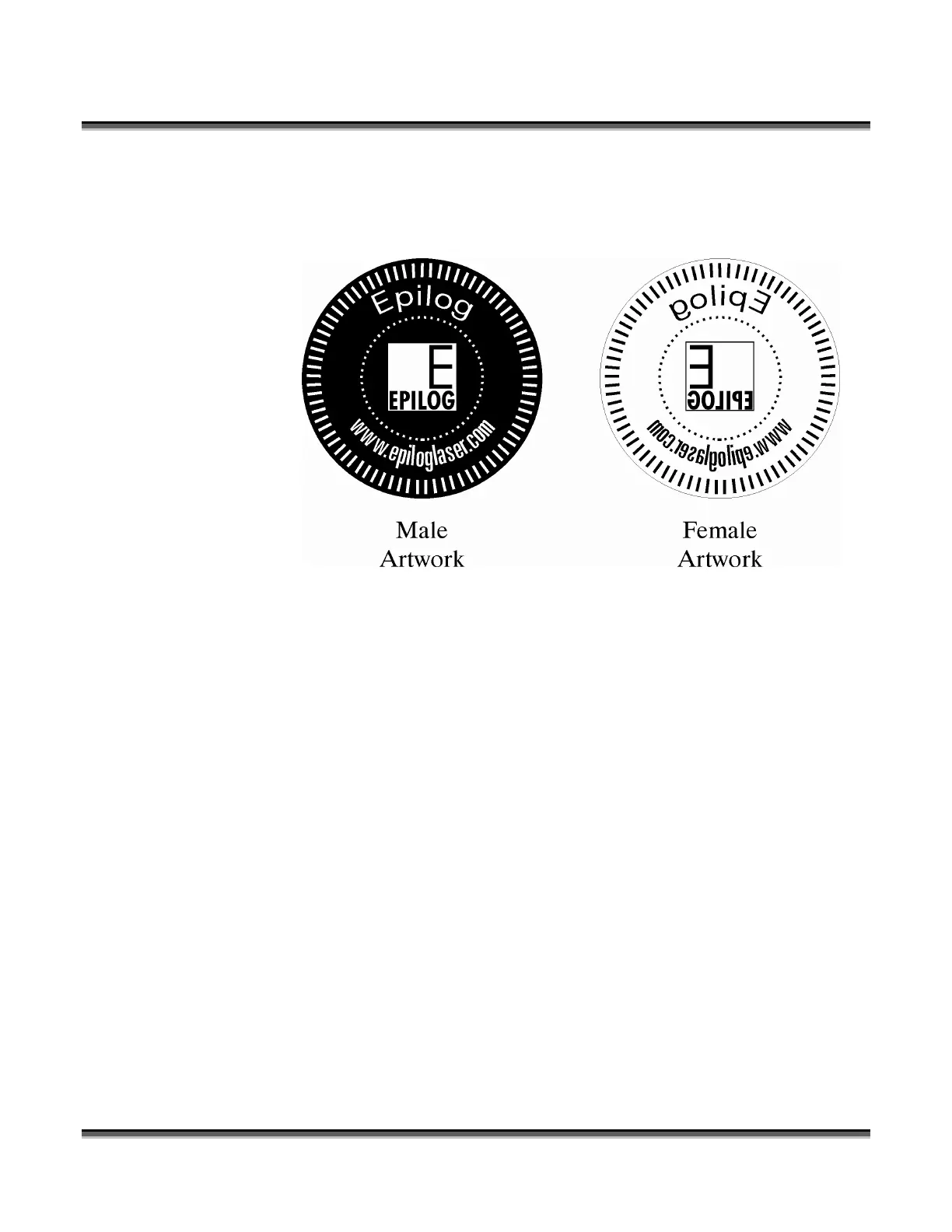

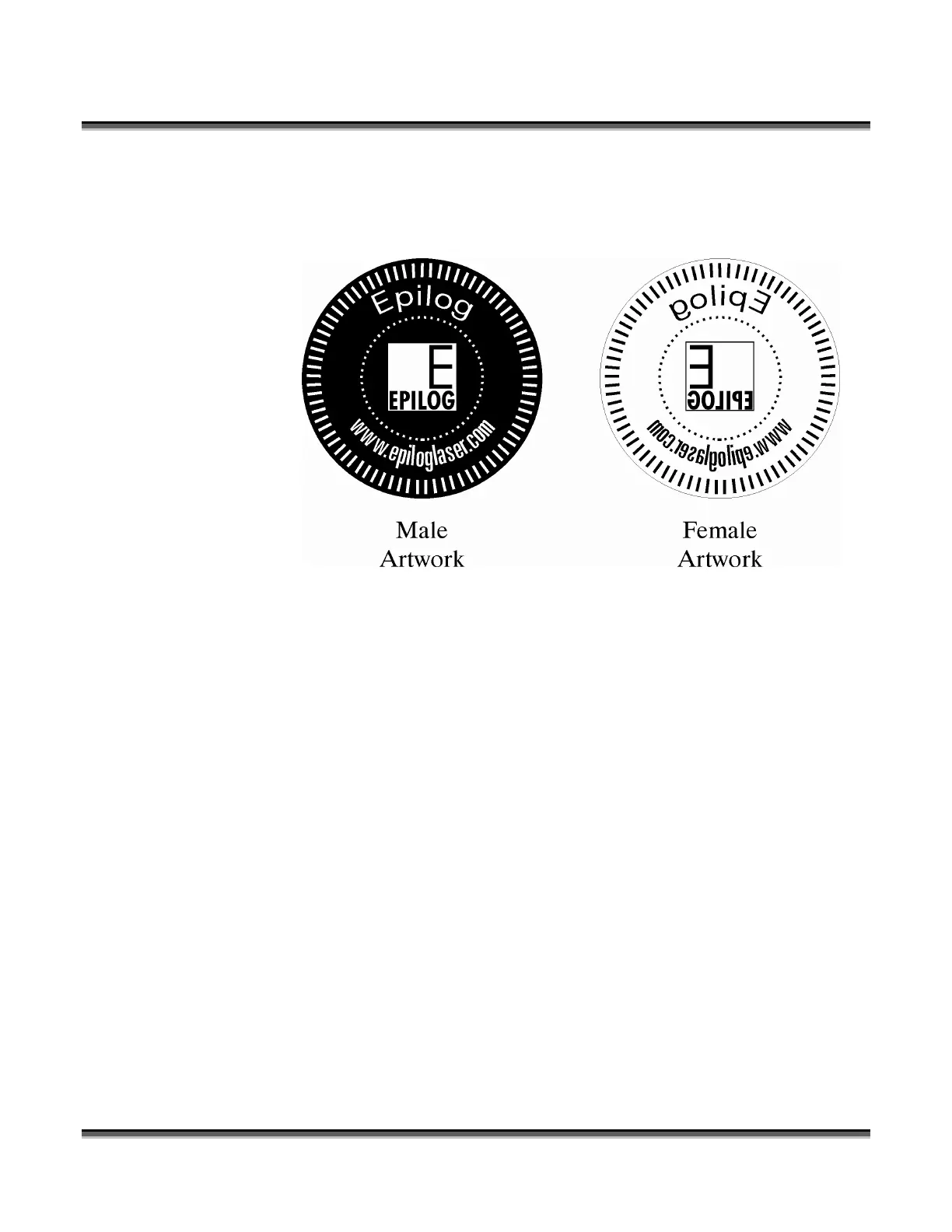

Apply a .001 outline around the seal to define the outside edge of the seal. Use the

combined Engraving/Vector mode to first engrave the seal and then cut out the seal.

Plastic

Plastic Background

Engraving plastics have changed greatly in the past few years. Before lasers, plastic

manufacturers designed plastic for rotary engraving systems. A rotary engraving

system uses a mechanical spinning bit to remove material. Therefore the depth of the

top layer or “cap sheet” was designed to make it easy to rotary engrave. Cap sheet

thickness was approximately .010 inches thick and laser engraving was nearly

impossible because by the time you applied enough power to get through the cap

sheet the laser melted and deformed the plastic.

Plastic manufacturers have developed a broad range of plastics that have thinner cap

sheets that are .002 to .003 inches thick that provide much better engraving and

cutting characteristics. These plastics are commonly referred to as Micro Laminates;

Micro surfaced, or simply laser engravable plastics. These plastics are generally very

easy to engrave with a laser since they all have similar characteristics.

Because there is such a broad range of plastics it is necessary to experiment to

determine if a particular type of plastic is laser compatible. Different color plastics,

Loading...

Loading...