Drilled Hole

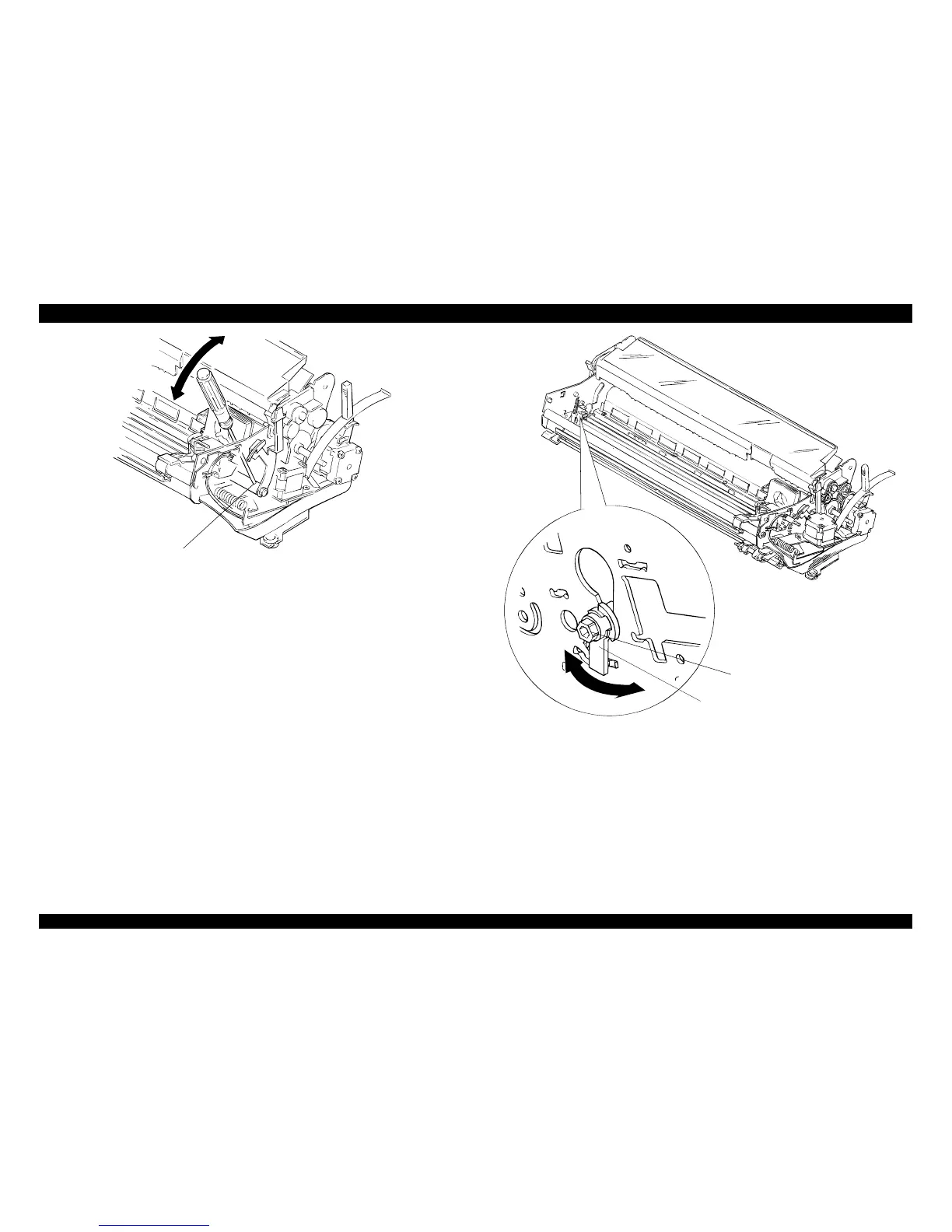

Figure 5-3. Platen Gap Adjusting

10. When the gap is correct at the 5

th

column, check the platen gap at the

center column, and then the right edge column position.

11. If the platen gap is wider at the left edge column than right edge

column, adjust the parallelism for rear CR guide shaft by moving the

parallelism adjustment bushing backward. If the platen gap is more

narrow for the left edge column than the right edge column, adjust the

parallelism of the CR guide shaft by moving the parallelism adjustment

bushing forward. Refer to the following figure.

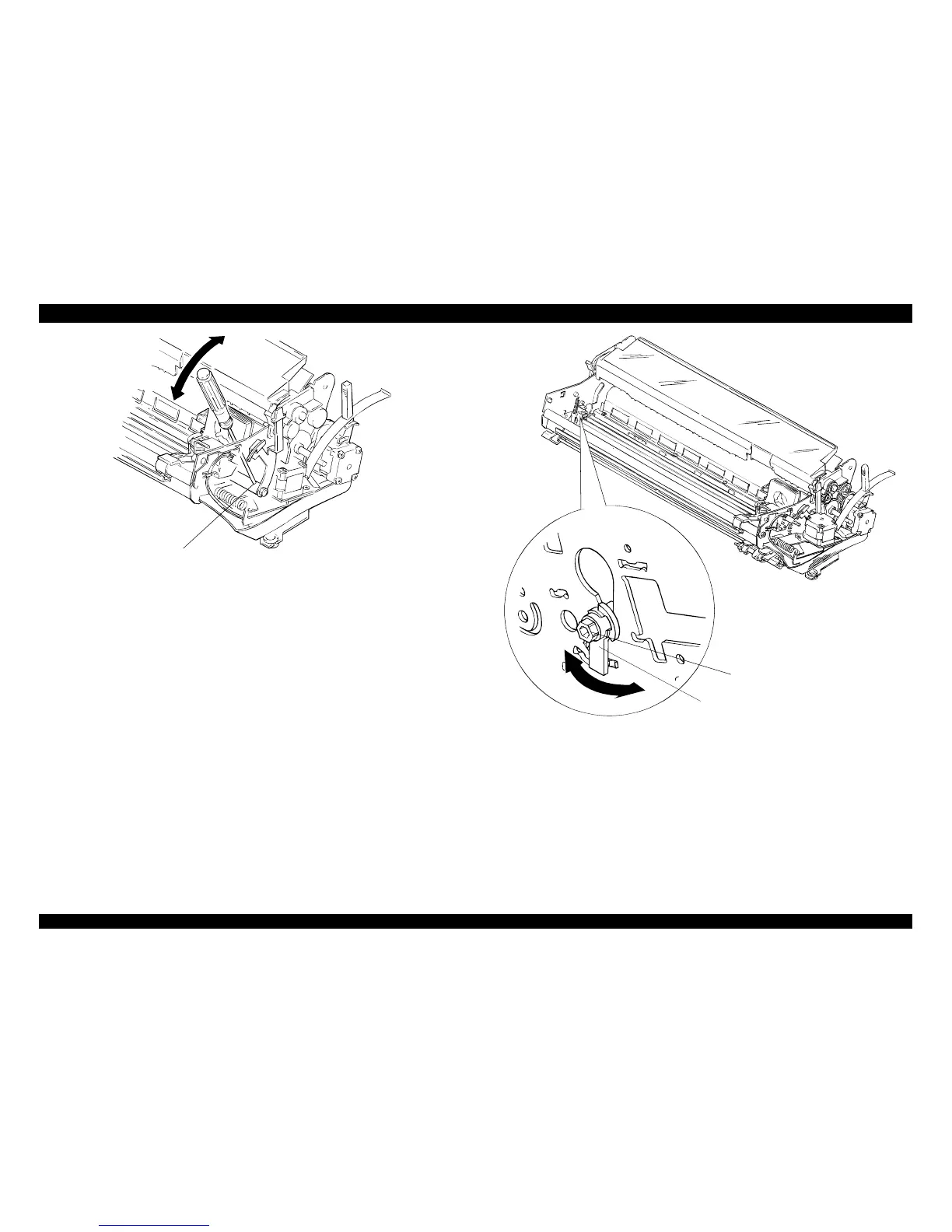

Parallelism Adjustment Bushing

Hexagon Nut

Figure 5-4. Adjusting the Parallelism of the CR Guide Shaft

12. Continue performing adjustment step 8 to 11 until the platen gap

correct at all 3 positions. After completing the adjustment, remove the

screwdriver from the rear CR guide shaft.

13. After inserting the ribbon mask in the ribbon mask holder and installing

the printhead into CR assembly, tighten two CBS screws (3

×

8) to

attach the printhead.

14. Tighten the hexagon nut (M4) securing the PG adjust lever.

Loading...

Loading...