4.2.9.11 Removing the Main Board Assembly

1. Remove the printer cover, the rear / front edge guide assemblies, front

cover, paper eject assembly, and rear / fronts tractor units. (Refer to

Section 4.2.1.)

2. Remove the panel board assembly. (Refer to Section 4.2.2.)

3. Remove the upper housing assembly. (Refer to Section 4.2.7.)

4. Disconnect the following connectors from the main board assembly.

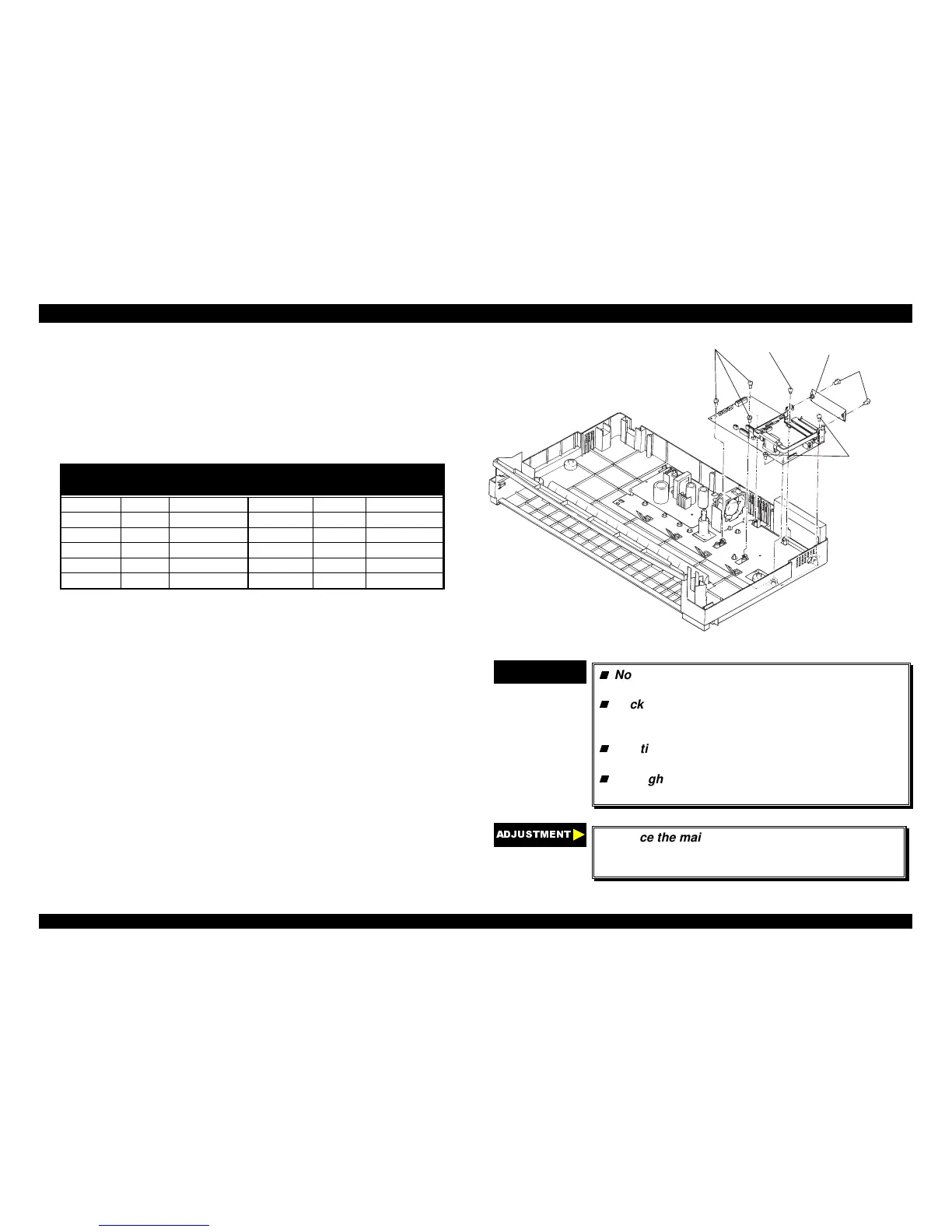

Table 4-8. Connectors’ List

Number Pin Connector

Color

Number Pin Connector

Color

CN3 10 white CN4 3 white

CN5 3 black CN6 2 white

CN7 4 gray CN8 18 gray

CN9 16 gray CN10 4 white

CN11 5 white CN12 4 white

CN13 4 black CN15 22 white

Note1 :Disconnect the cable for CN10 and CN11 after releasing the

connector locks by pulling up.

Note2 : Disconnect the cable for CN3 by pushing down the connector cover.

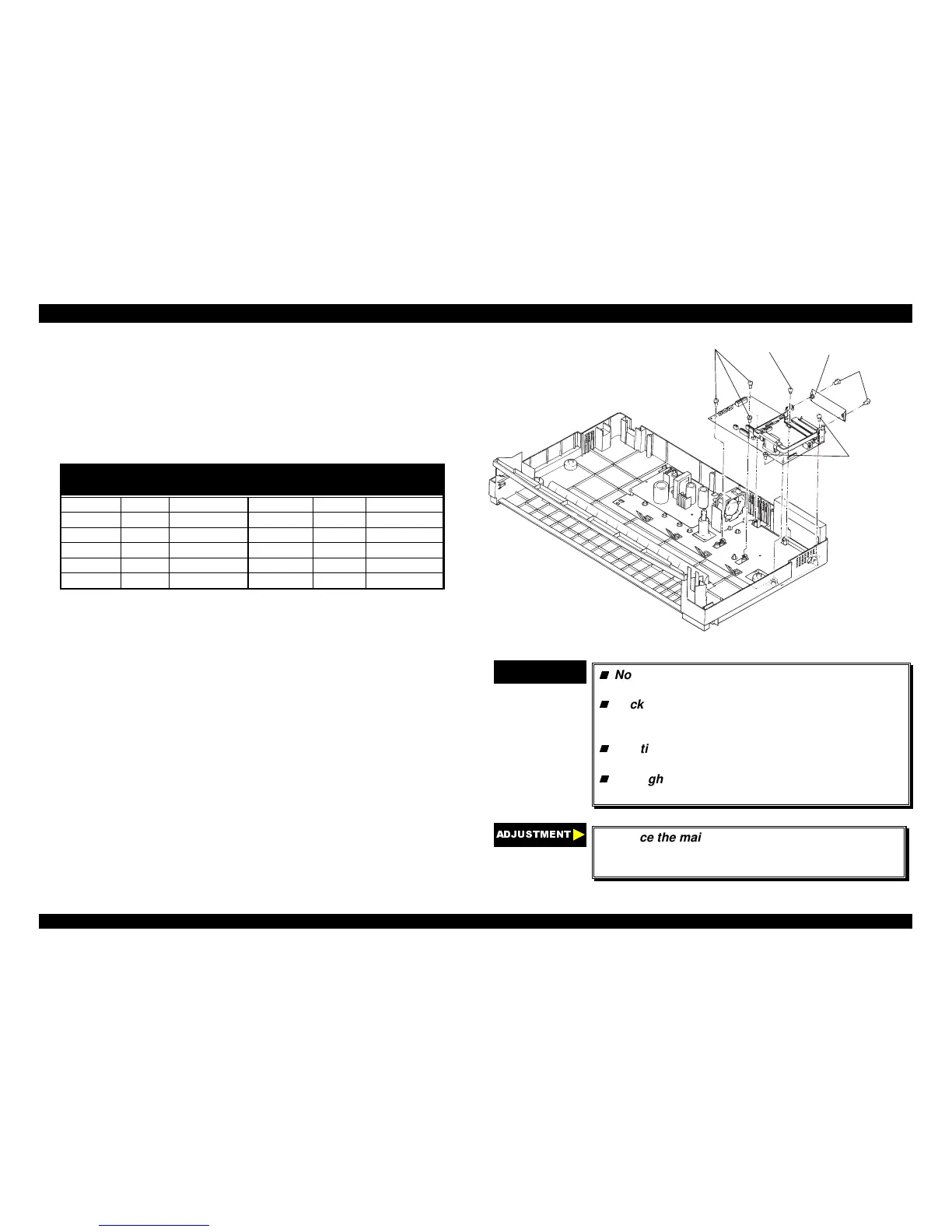

5. Remove three CBS screws (3 × 4) securing the upper shield plate to

the printer mechanism and the upper I/F grounding plate on the main

board assembly.

6. Remove two CBS screws (3 × 12) securing the upper connector cover.

7. Remove five CBS screws (3 × 12) and one CBC lamitite screw (3 × 8)

securing the main board assembly to the lower housing assembly.

8. Remove the option I/F cage from the main board by releasing the hooks

which is fixing it to the main board.

9. Remove the main board assembly with the upper I/F grounding plate.

CBS(3x12)

CBB(3x12)

CBC(3x8)

CBB(3x12)

U pper C onnector C over

Figure 4-35. Removing the Main Board Assembly

CHECK POINT

9

Notice the location of CBC lamitite screw (3 ×× 8)

refer to the following figure.

Lock CN10 and CN11 by pushing down each

connector’s lock after inserting the connector

cable.

The tightening torque for the CBB screws (3 ××

12) : 0.78 ∼∼ 0.98 Nm (8 ∼∼ 10 Kgf-cm)

The tightening torque for the CBB screws (3 ×× 8)

: 0.78 ∼∼ 0.98 Nm (8 ∼∼ 10 Kgf-cm)

$'-8670(17

If replace the main board, adjust the bi-directional

print alignment and run the default setting

program. (Refer to Chapter 5.)

Loading...

Loading...