REV.-A

● Do not perform reverse feeding for more than 1/6 inches.

f’”

● Because accuracy of paper feed cannot be assured, do not perform reverse feeding ‘

after the paper end has been detected.

b) When using pull tractor feed:

● Remove the paper tension unit and mount the pull tractor unit.

● Use the paper path when a single sheet is inserted.

c) When using push-pull tractor feed:

● Remove the paper tension unit and mount the pull tractor unit.

● Do not loosen the paper between the platen and the pull sprocket.

● -Precisely the horizontal position of the pull sprocket and push tractor.

● Do not perform reverse feeding after the paper end has been detected.

Paper Loading Directions

Fanfold paper

Inserted from the rear side

Cut sheet paper

Inserted from the up side

Line Spacing

1/6” or programmable (min.

Line Feed Speed See Table 1-3.

1/2 16“)

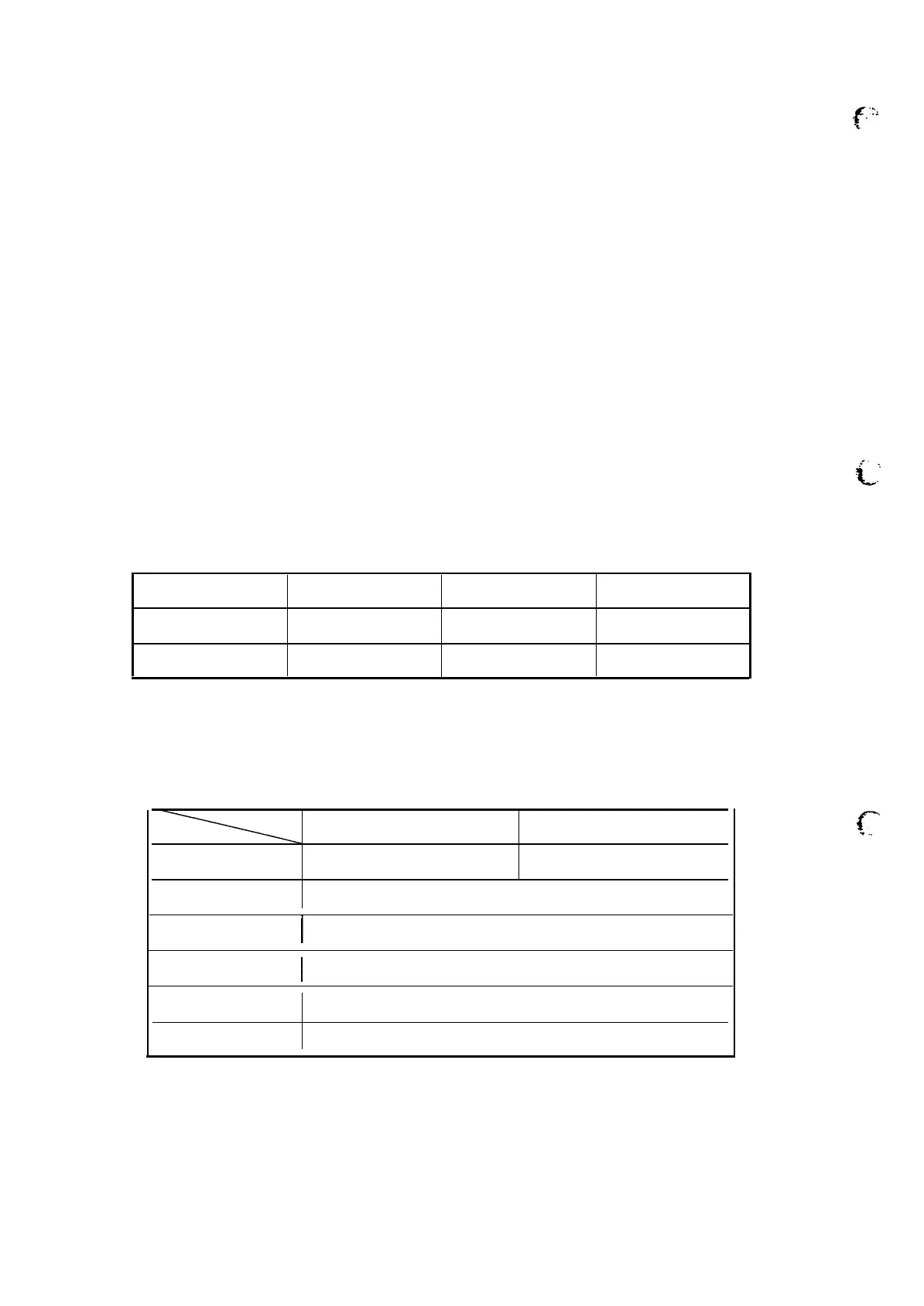

Table 1-3. Line Feed Speeds

Type of Paper Continuous Feed Intermittent Feed Feed Speed

Cut Sheet

48 ins/line 71 ins/line 3.5 “/see

Fanfold

53 ins/line 76 ins/line

3.1 “/see

Paper Specifications

Cut sheet paper Refer to Table 1-4.

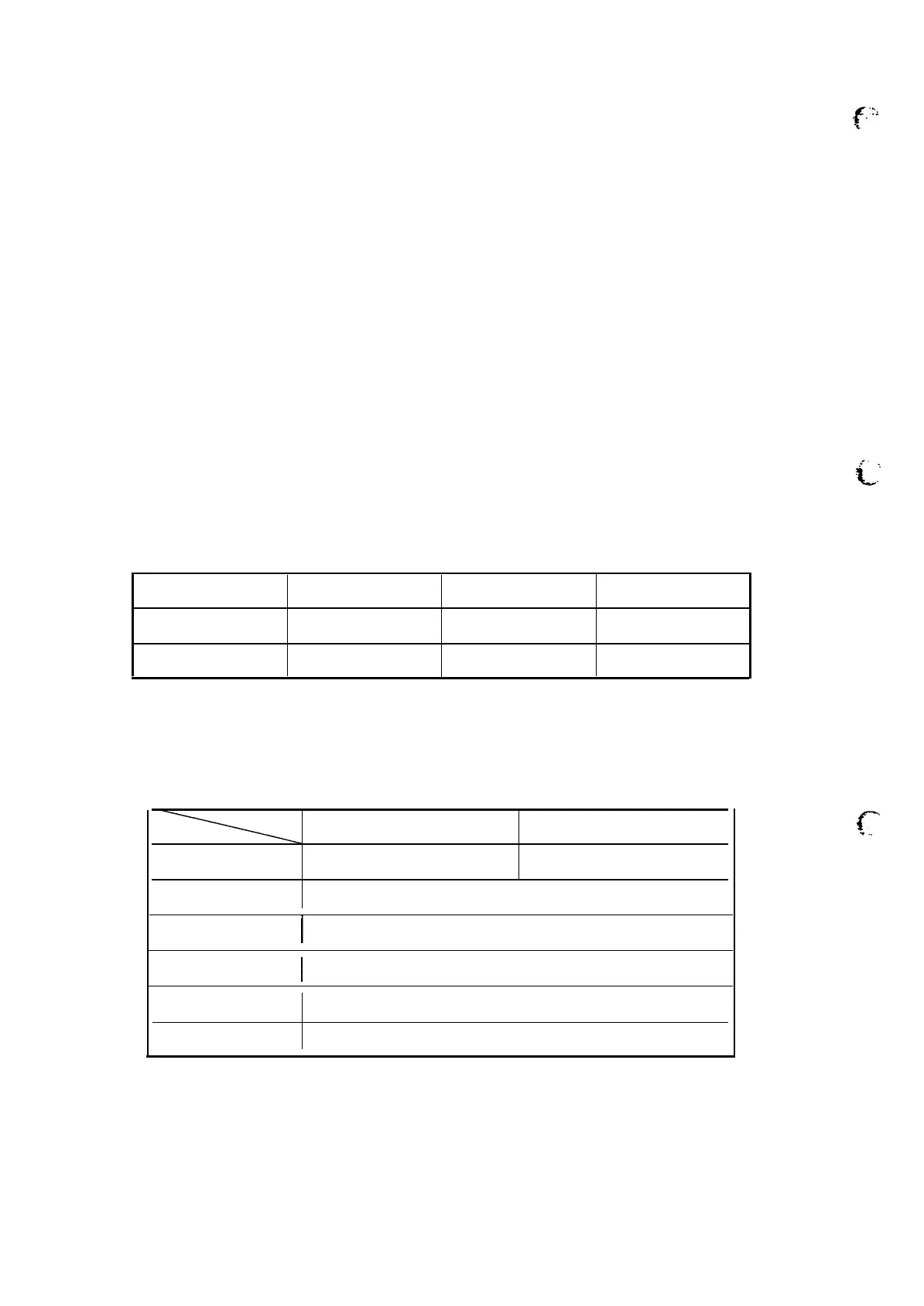

Table 1-4. Cut Sheet Paper Specified Conditions

FX-850 FX-1 050

Width [mm] 182-257 (7.2 - 10.1”) 182-366 (7.2 - 14.4”)

Length

[mm] 182 -

364 (7.2 - 14.3”)

Thickness [mm]

I

0.065 -

0.10 (0.0025 - 0.004”)

Weight [Kg]

I

45 - 70 (14 - 22 lb)

Quality Plain paper

Copies

Not available

f-

.

.

.

NOTE: The form overriding mechanism enables printing as close as 13.5 mm from the bottom edge

of the paper. However, paper feed accuracy is not guaranteed within about 22 mm from the

bottom.

1-4

Loading...

Loading...