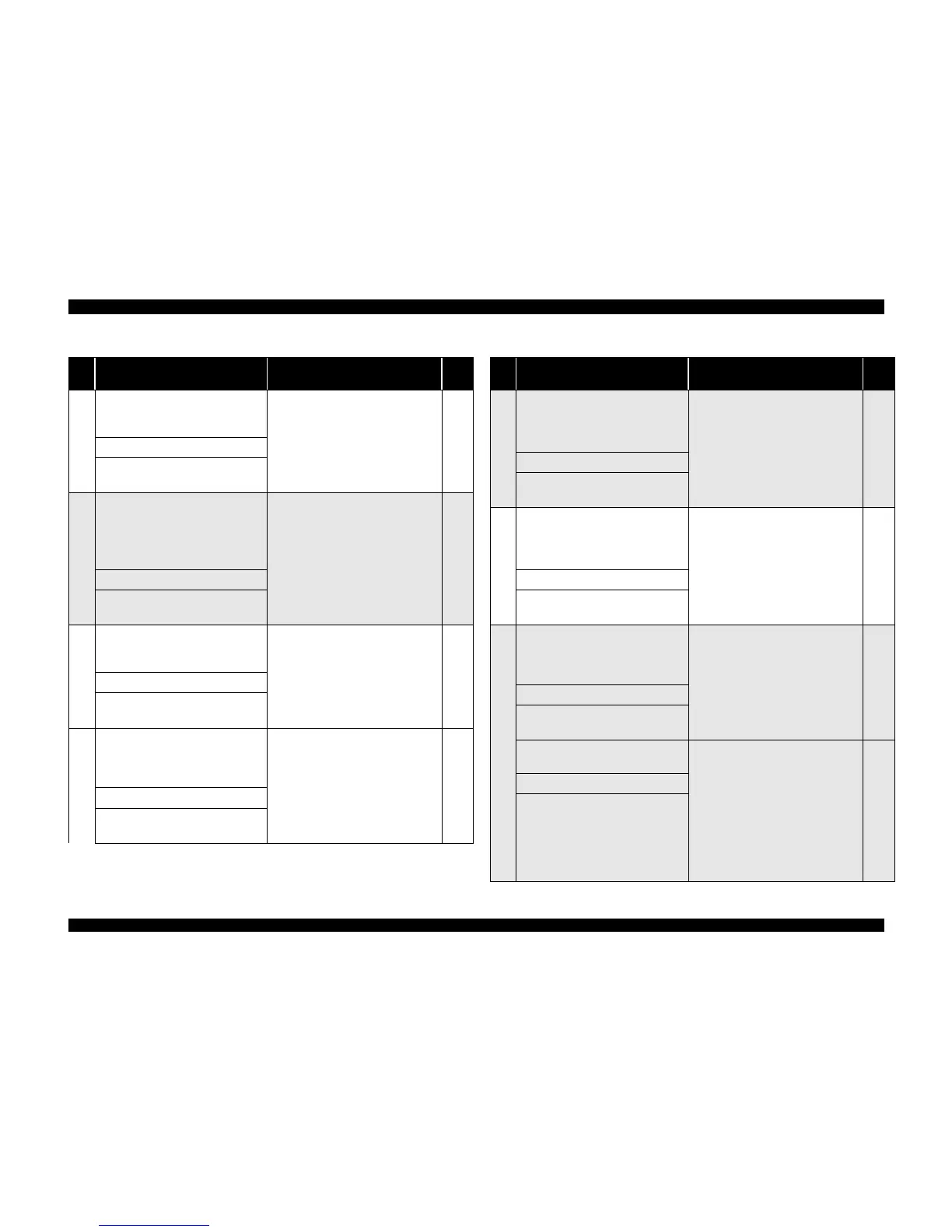

5

<Lubrication Point>

The shaft for “GEAR, 16, 40.8” on

“FRAME, LEFT”

Use a syringe to apply it. 138

<Lubricant Type> G-26

<Lubrication Amount>

Approximately 5-mm long

6

<Lubrication Point>

Bushings for “ROLLER, PF”

Left: Inside the bushing

Right: Inside the bushing (near the

pump assembly)

For the right bushing, apply it from the

paper path side, and wipe off any grease

sticking out to the cap assembly side.

Rotate “ROLLER, PF” after applying

grease to evenly distribute it in the

bushing.

Use a syringe to apply it.

139

<Lubricant Type> G-26

<Lubrication Amount>

Approximately 3 mm diametrically

7

<Lubrication Point>

Both Left/Right Bushings for

“ROLLER, EXIT”

Avoid applying grease around the paper

path.

Use a syringe to apply it.

139

<Lubricant Type> G-26

<Lubrication Amount>

Evenly apply inside the bushings.

8

<Lubrication Point>

Contact points between “HOLDER,

PULLEY, DRIVEN” and “FRAME,

UPPER”

Verify that the holder slides only with

spring force after applying grease.

Use a syringe to apply it.

140

<Lubricant Type> G-26

<Lubrication Amount>

2-mm long for each point

Table 6-2. Lubrication Points (continued)

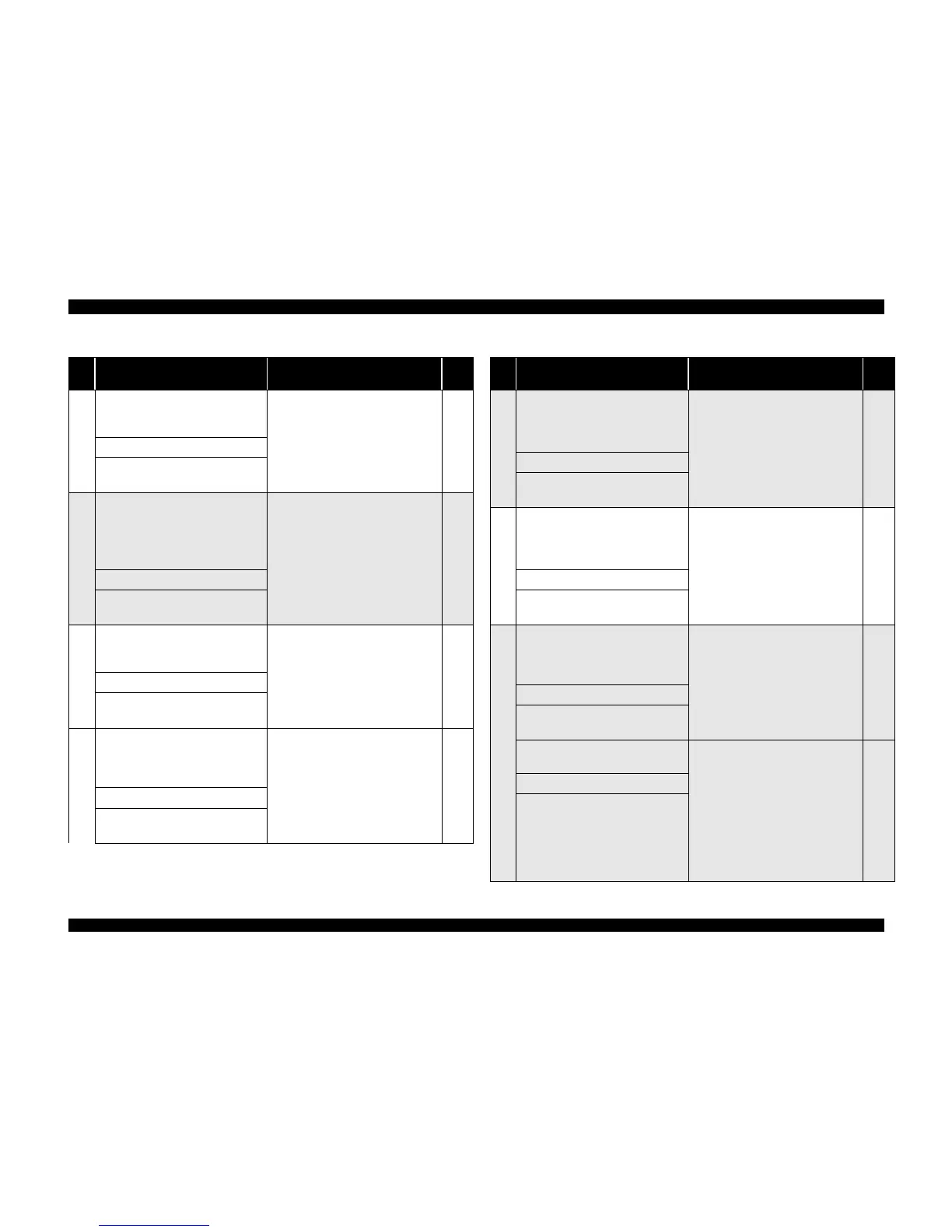

No. Standard Remarks

See

page

9

<Lubrication Point>

ASF;

The round hole in the right frame of

ASF (to hold the roller shaft)

Avoid applying grease to “ROLLER,

ASSEMBLY, LD”.

140

<Lubricant Type> G-26

<Lubrication Amount>

Evenly apply inside the hole.

10

<Lubrication Point>

ASF;

Contact points between “HOPPER” and

“LEVER, HOPPER, RELEASE”

Completely wipe off any grease sticking

out to the inner side of ASF.

140

<Lubricant Type> G-26

<Lubrication Amount>

Evenly apply lubrication to the points.

11

<Lubrication Point>

The round cutout in the left frame of

ASF (“GEAR, 34” is inserted to the

cutout.)

Completely wipe off any grease sticking

out to the inner side of ASF.

141

<Lubricant Type> G-26

<Lubrication Amount>

Evenly apply inside the hole

12

<Lubrication Point>

Oil pad in the carriage assembly

Lubricate the oil pad only when:

Replacing the carriage assembly

Replacing the oil pad

Use a precise syringe to apply oil. If you

accidentally apply too much oil to the oil

pad, throw the pad away and take a new

one again.

Leave the pad for a while to wait until

oil is evenly infiltrated, then install it on

the carriage assembly.

141

<Lubricant Type> O-12

<Lubrication Amount>

0.72 ~ 0.77cc (0.65 ~ 0.69g)

Note:

This is the amount to be applied to a

new oil pad.

Table 6-2. Lubrication Points (continued)

No. Standard Remarks

See

page

Loading...

Loading...