5 GOUGING

0460 949 274

- 23 -

© ESAB AB 2015

5 GOUGING

The process is available for certain machine types.

Main menu → Process

With arc air gouging, a special electrode comprising a carbon rod with a copper casing is

used.

An arc is formed between the carbon rod and the work piece, which melts the material. Air is

supplied so that the melted material is blown away.

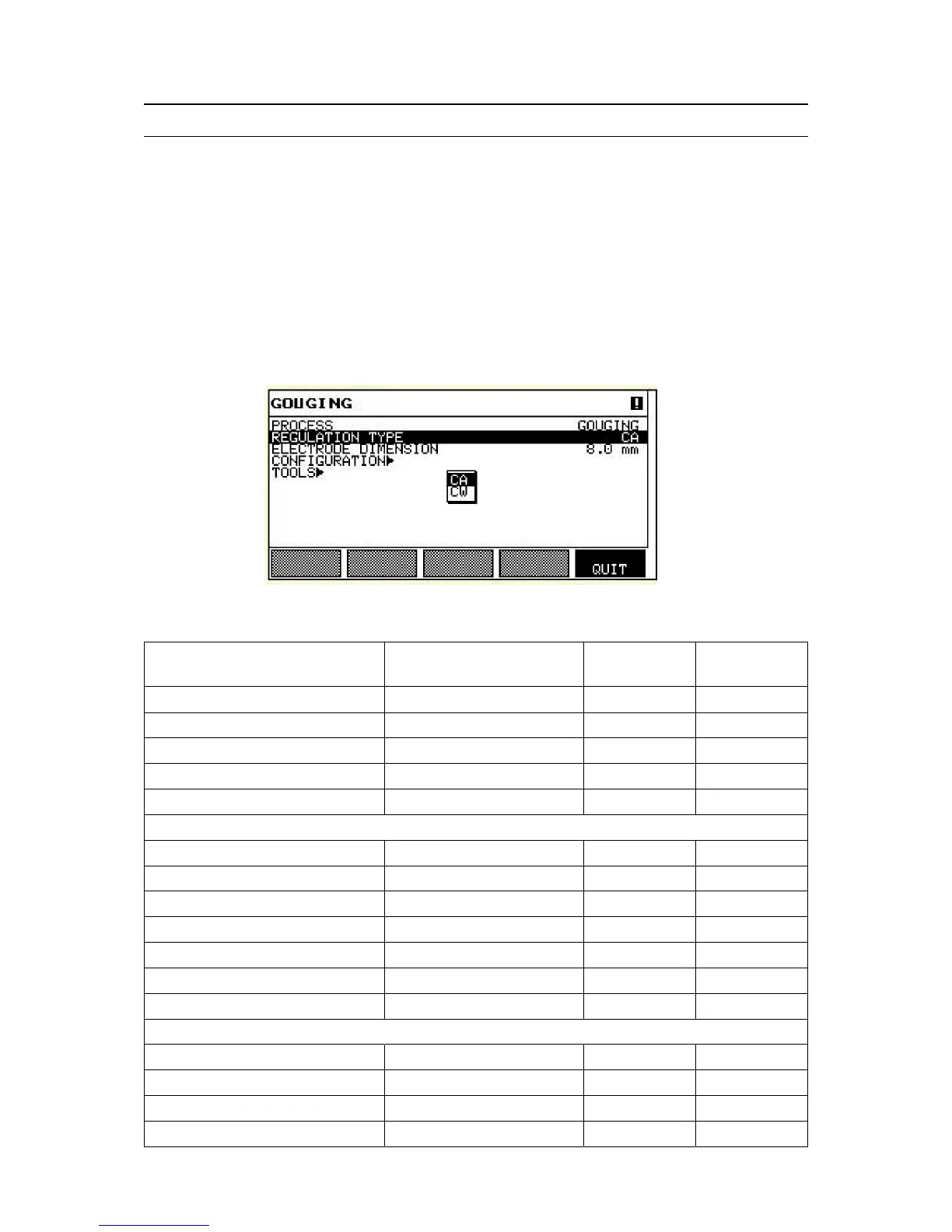

When the GOUGING process is selected, you can choose between two control methods by

marking REGULATION TYPE using the positioning knob and pressing ENTER. Choose

between constant amperage CA or constant wire feed CW, see explanation in “CA, constant

amperage”, page25 and “CW, constant wire feed”, page25.

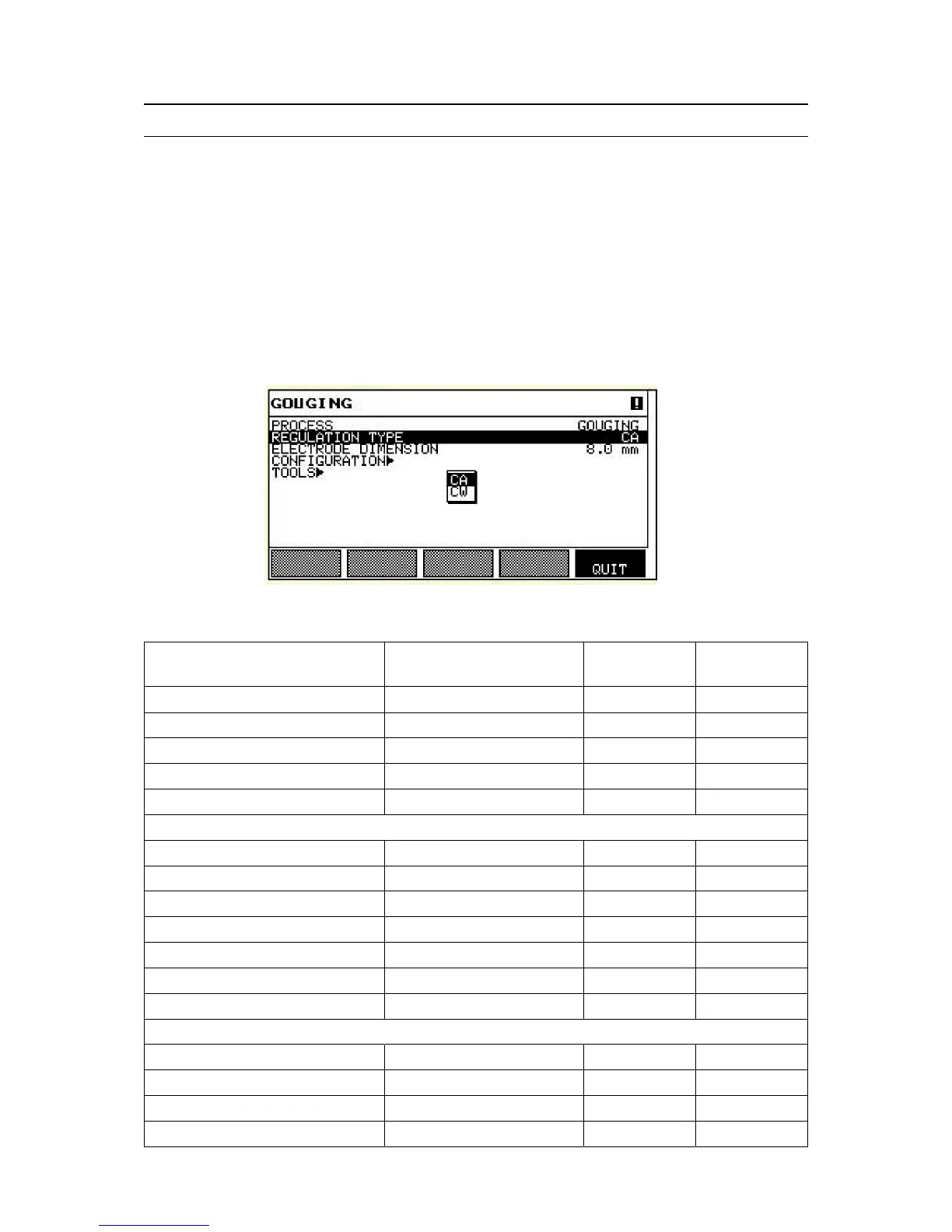

5.1 Settings for gouging

Settings Setting range In steps of Value after

resetting

Arc voltage* 14 - 50 V 0.1 V (1V) 30 V

Welding current* (CA) 0 - 3200 A 1 A 400 A

Wire feed speed* (CW) 0 - 2500 cm/min 1 cm/min 300 cm/min

Travel speed* 0 - 200 cm/min 1 cm/min 40 cm/min

Welding direction ▲-■ - ■

Start data

Air pre-flow 0 - 99.0 s 0.1 s 0 s

Start type Direct or Scrape - Direct

Wire creep start Auto or Set speed - Auto

Wire creep start speed 0 - 1000 cm/min 1 cm/min 20 cm/min

Start phases OFF or ON - OFF

Open-circuit voltage OFF or ON - OFF

Maximum open-circuit voltage 5 - 60 V 0.1 V 50 V

Stop data

Air post-flow 0 - 99.0 s 0.1 s 0 s

Crater filling OFF or ON - OFF

Crater filling time 0 - 10 s 0.01 s 1 s

Burnback time 0 - 10 s 0.01 s 1 s

Loading...

Loading...