9 TOOLS

0460 949 274

- 58 -

© ESAB AB 2015

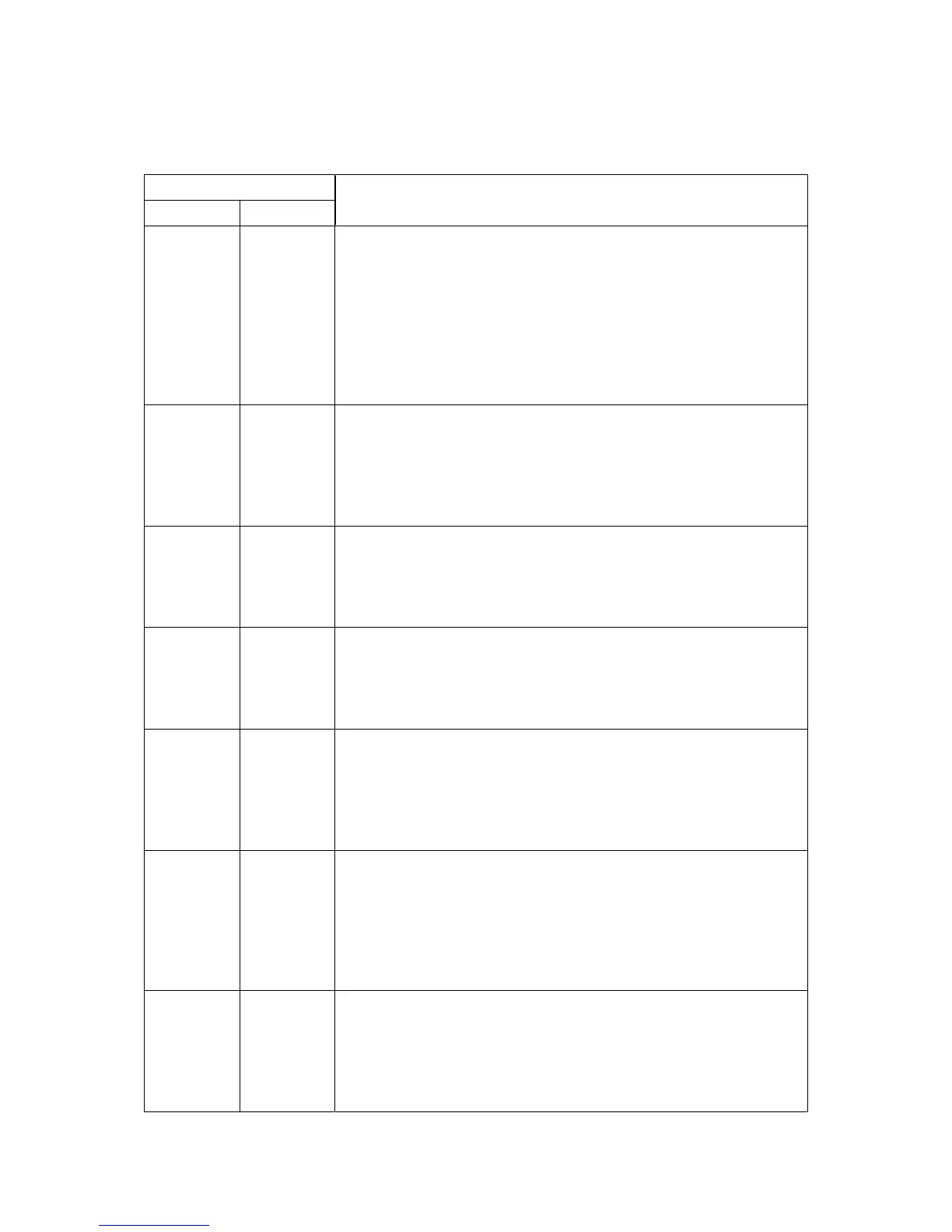

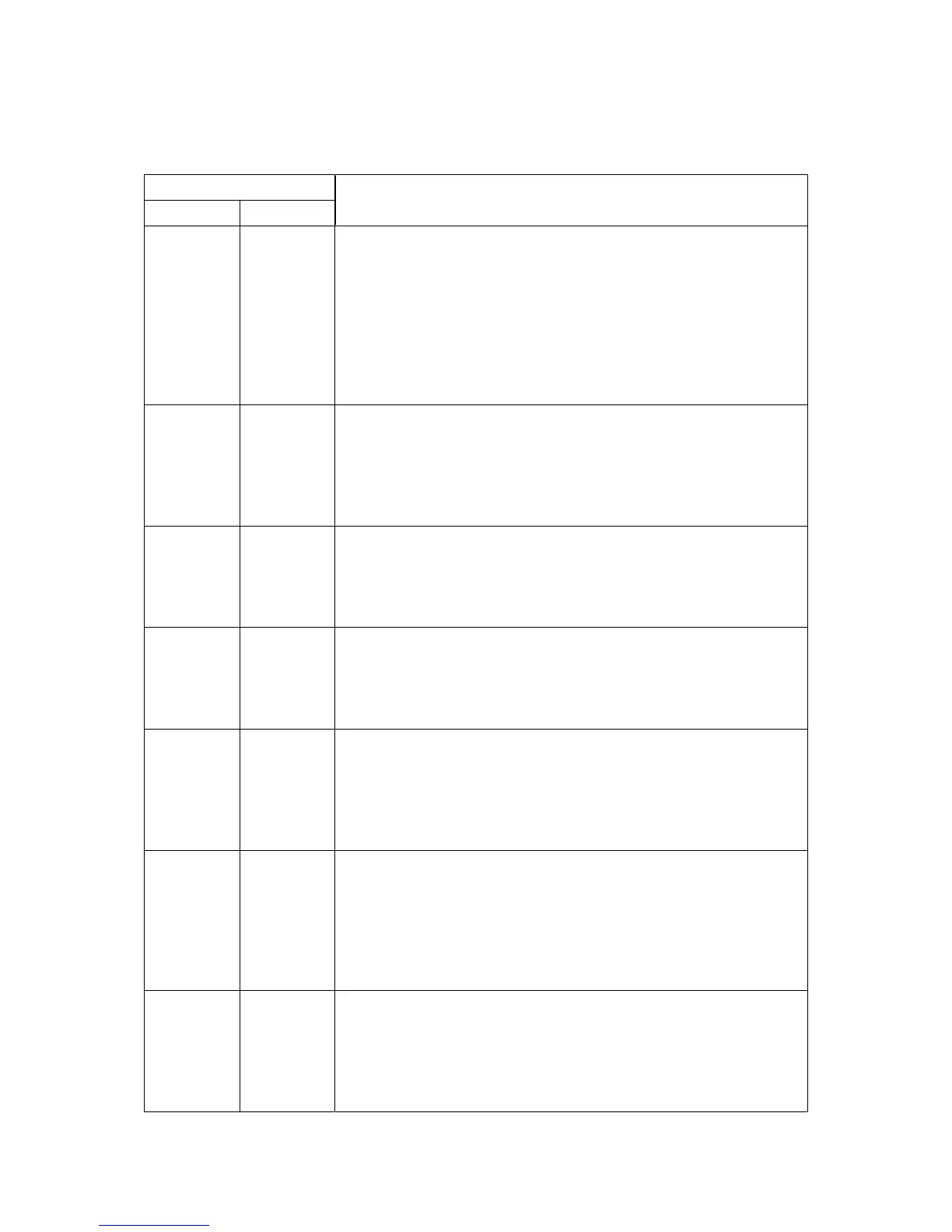

9.1.4 Description of fault management codes

The fault management codes that users can correct themselves are given below. If another

code appears, restart the machine and if the error persists, contact a service technician.

Error code Description

LAF, TAF Aristo 1000

6 4201, 4202,

4203

High temperature

The power source has overheated and cancels welding. Welding

is permitted again when the temperature falls below the

maximum temperature parameter.

Action: Check that the cooling air inlets or outlets are not

blocked or clogged with dirt. Check the duty cycle being used, to

make sure that the equipment is not being overloaded. If the

error persists, send for a service technician.

7 Low welding current

The weld arc has been shut down due to too low welding current

during the welding process.

Action: Is reset at next weld start. If the error persists, send for a

service technician.

8 Low battery voltage

Battery voltage too low. If the battery is not replaced, all stored

data will be lost. This error does not disable any functions.

Action: Send for a service technician to replace the battery.

11 8411

sub-code 0

Speed error on a motor, (wire feed, travel motor)

A motor cannot maintain its speed. Welding stops.

Action: Check that the wire feed has not jammed or runs too

fast. If the error persists, send for a service technician.

12 Internal communication error (warning)

The load on the system's CAN-bus is temporarily too high. The

power source may have lost contact with the control unit.

Action: Check that all the equipment is correctly connected. If

the error persists, send for a service technician.

14 Communication error

The system's CAN-bus has temporarily stopped working due to

the load being too high. The current welding process stops.

Action: Check that all the equipment is correctly connected. Turn

off the mains power supply to reset the unit. If the error persists,

send for a service technician.

17 8117 Lost contact with the unit

Lost contact with a unit.

Action: Check wiring and the connector between the control unit

and power source. If the error persists, send for a service

technician.

Loading...

Loading...