9 TOOLS

0460 949 274

- 59 -

© ESAB AB 2015

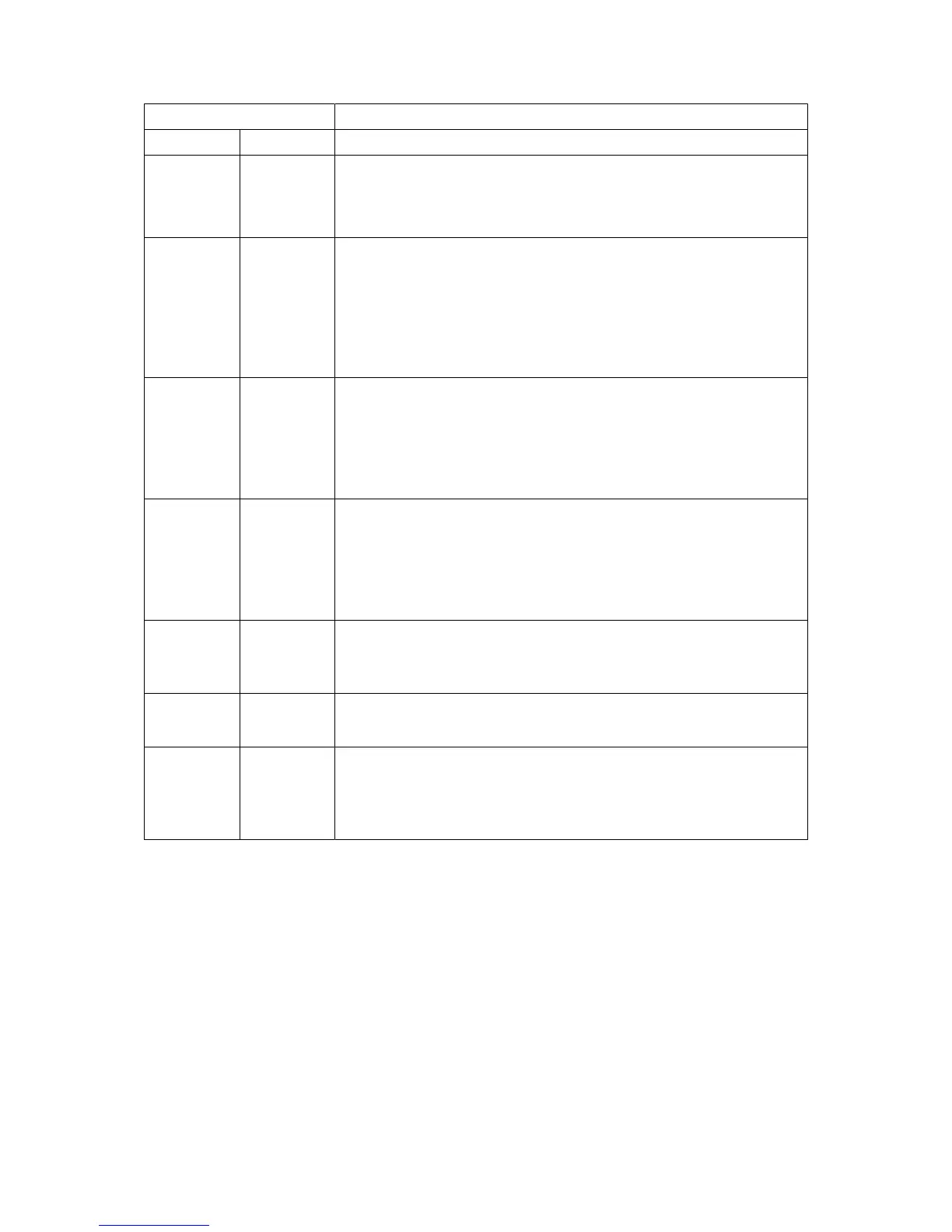

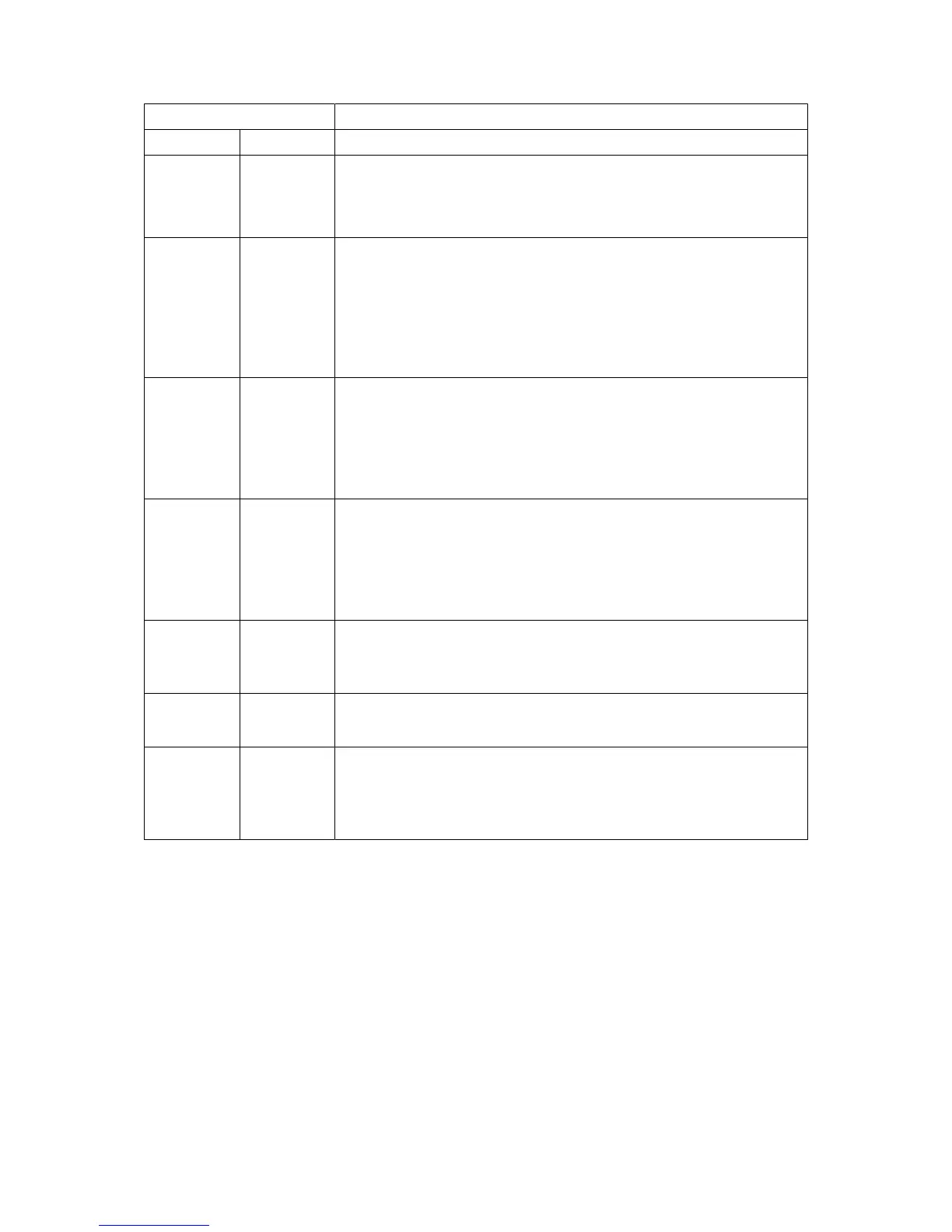

Error code Description

LAF, TAF Aristo 1000

32 No gas flow

Start prevented.

Action: Check the gas valve, hoses and connectors.

43 High welding current

Power source have switched off the welding process because the

current has exceeded the maximum current parameter for the

power source.

Action: Is reset at next weld start. If the error persists, send for a

service technician.

44 Start pause welding current

The welding process has stopped because it has not advanced

within 10 seconds.

Action: Is reset at next weld start. If the error persists, send for a

service technician.

168, 169 8411

sub-code 1

A motor has stopped.

There are no pulses from the motor pulse transducer.

For LAF and TAF: 168=MotorM1(Wirefeedermotor),

169=MotorM2(Travelmotor)

Action: Check the motor cables. Replace the pulse transducer.

2310 Current servo saturation

The power source has temporarily delivered maximum current.

Action: If the error persists, try lowering the weld data.

3205 High DC voltage

Action: Check if the main voltage is too low or too high.

5010 High inductance

Inductance is too high, depending on long welding cables and/or

high weld data.

Action: Try adjusting the weld data.

9.2 Export/Import

Main menu → Tools → Export / Import

In the Export/Import menu, it is possible to transfer information to and from the control panel

via a USB memory.

The following information can be transferred:

• Weld data sets Export / Import

• System setting Export / Import

• Setting limits Export / Import

• Measure limits Export / Import

• Error log Export

Loading...

Loading...