3 SUBMERGED ARC WELDING

0460 949 274

- 19 -

© ESAB AB 2015

3 SUBMERGED ARC WELDING

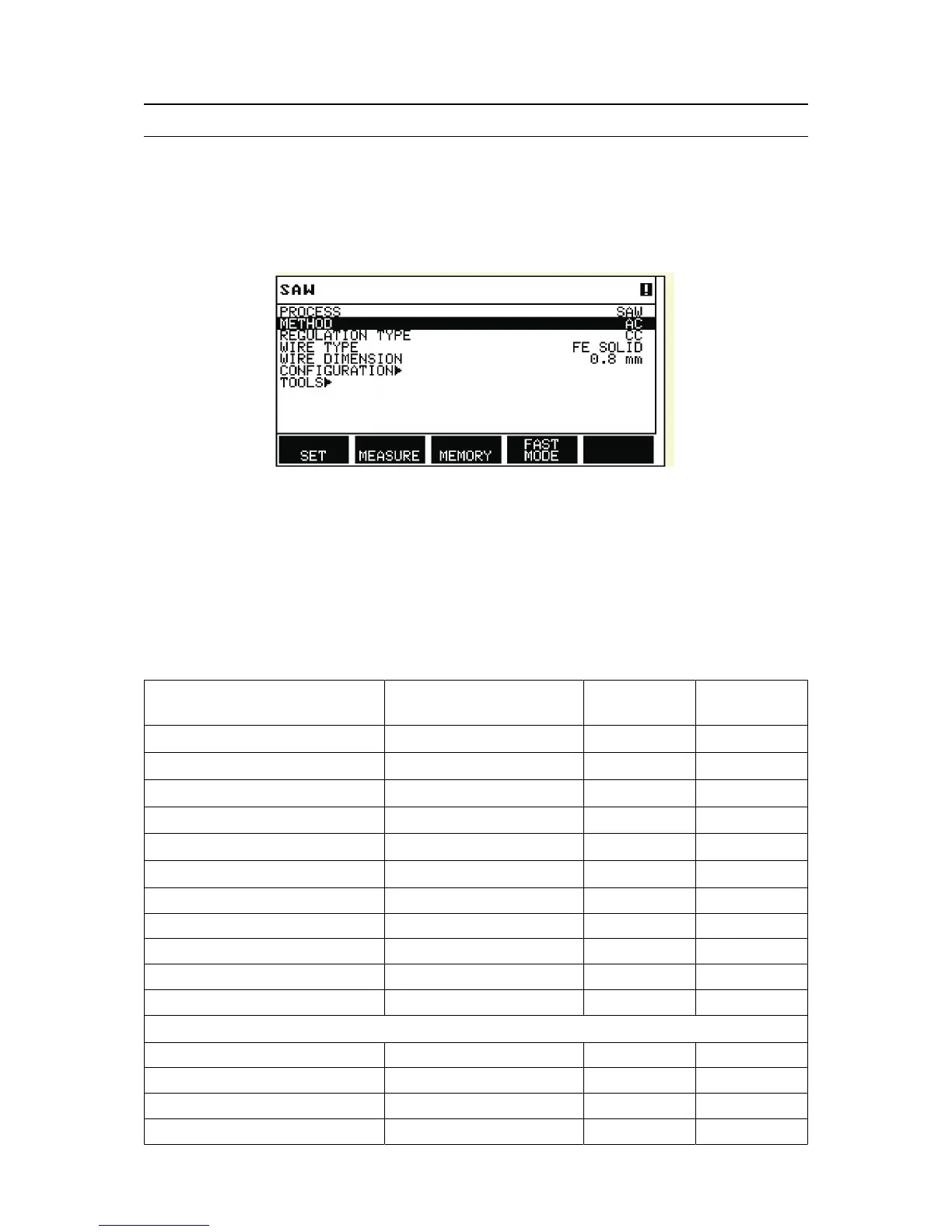

Main menu -> Process

During Submerged Arc Welding (SAW), an arc melts a continuously supplied wire. The weld

pool is protected by flux.

When the SAW process is selected, you can choose between two methods by marking

METHOD using the positioning knob and pressing ENTER. Choose between AC or DC.

When the SAW process is selected, you can choose between three control methods by

marking REGULATION TYPE using the positioning knob and pressing ENTER. Choose

between constant welding current CA or constant wire feed CW or constant current CC

(CCapplies only to Aristo1000), see explanations in “CA, constant amperage”, page25,

“CW, constant wire feed”, page25 and “CC, constant current”, page25.

If Ice wire feed is selected, see “Ice wire feed”, page52, only regulation type CW can be

selected.

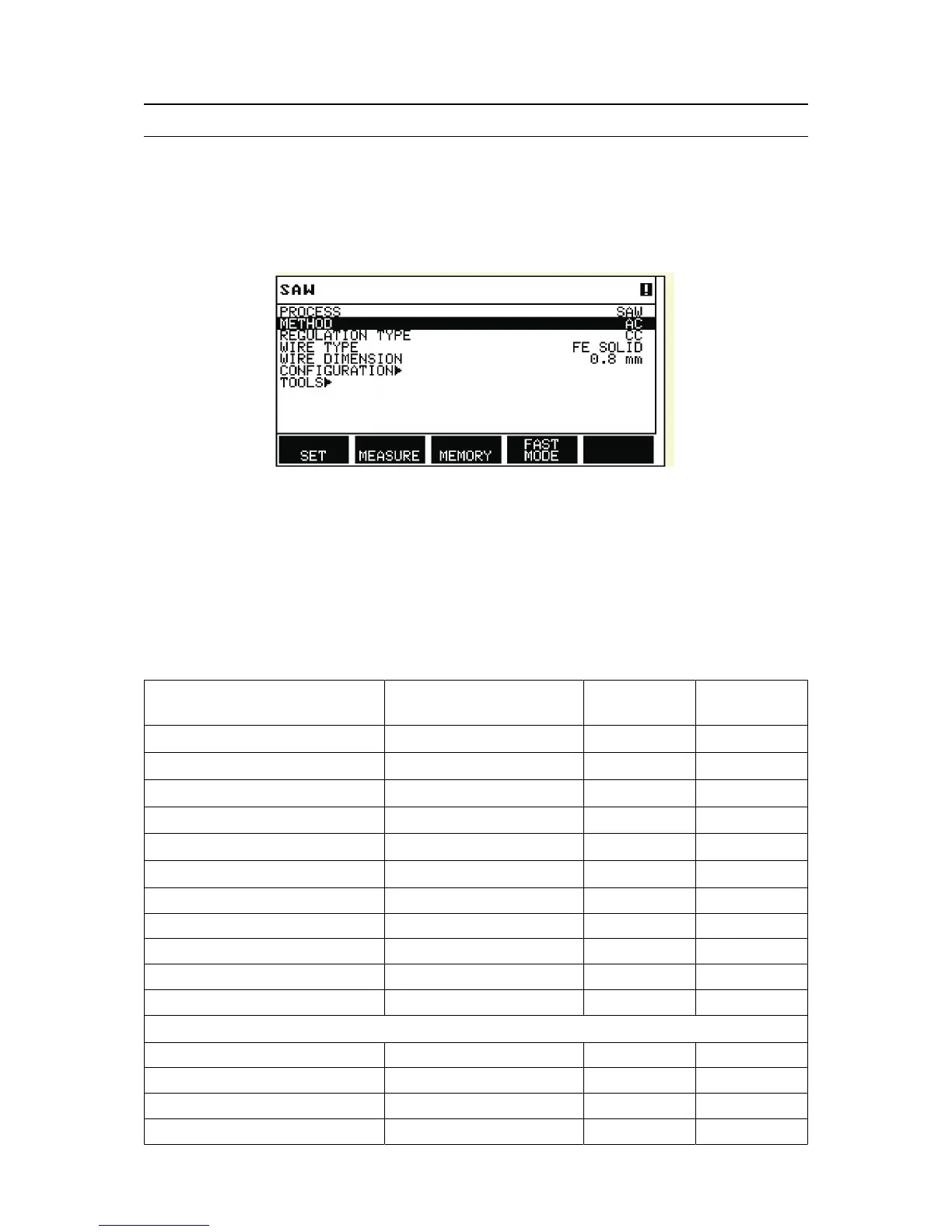

3.1 Settings for submerged arc welding

Settings Setting range In steps of Value after

resetting

Arc voltage

1)

14 - 50 V 0.1 V (1V) 30 V

Welding current

1)

(CA)

0 - 3200 A 1 A 400 A

Wire feed speed

1)

(CW)

0 - 2500 cm/min 1 cm/min 300 cm/min

Constant current

1) 3)

(CC)

0 - 3200 A 1 A 400 A

Cold wire feed speed

1)

(CW)

0 - 2500 cm/min 1 cm/min 300 cm/min

Cold wire start delay

1)

(CW)

0 - 99,0 s 0,1 s 2,5 s

Travel speed* 0 - 200 cm/min 1 cm/min 50 cm/min

Welding direction ▲-■ - ■

AC frequency 10 - 100 Hz 1 50 Hz

AC balance 25 - 75% 1 50%

AC offset -300 - +300 A/-10 - +10V 1 A / 0.1 V 0

Start data

2)

Flux pre-flow 0 - 99.0 s 0.1 s 0 s

Start type Direct or Scrape - Direct

Wire creep start Auto or Set speed - Auto

Wire creep start speed 0 - 1000 cm/min 1 cm/min 20 cm/min

Loading...

Loading...