Technical Manual

hD8625 8-

5

/

8

” 35K Tong

7.5

hyDraulic coMponenTs

Technical Information - Two Speed Motor

DISPLACEMENT CHANGE

When a motor is shifted from full to partial displacement the

motor is changed to 50%, 35%, or 28% of its original

displacement depending on its shift ratio.

STANDARD SHIFT RATIO

The standard 15 Series displacements of 15, 13, 9.5, 8, 7,

and 6 CID are available in the 15 Series Two Speed with a

shift ratio of 2:1. For example, a 15 CID motor shifted to

partial displacement becomes a 7.5 CID motor.

SPECIAL SHIFT RATIOS

There are two special displacements available in the 15

Series Two Speed which offer higher shift ratios, the 10.5

and the 11.5 CID. The 10.5 CID motor has a shift ratio of

3.5:1, which when shifted becomes a 3 CID motor. The 11.5

CID motor has a shift ratio of 2.875:1, which when shifted

becomes a 4 CID motor.

SHIFTING METHOD

Selecting between full and partial displacement is

accomplished by shifting the two-position spool valve

incorporated in the motor. Motors are available in either

single or double pilot configurations.

SINGLE PILOT

Single pilot motors require a pilot line to be connected to port

"C". When port "C" is pressurized the spool shifts the motor

to partial displacement. When port "C" is vented to tank, an

internal spring shifts the spool, returning the motor to full

displacement.

DOUBLE PILOT

Double pilot motors require two pilot lines. One line is

connected to port "C" while the other line is connected to

port "D". The motor is in full displacement when port "D" is

pressurized and port "C" is vented to tank. The motor is in

partial displacement when port "C" is pressurized and port

"D" is vented to tank.

OPEN DURING CROSSOVER SPOOLS

Open during crossover spools allow port "A" to be directly

connected to port "B" when the spool is shifting between full

and partial displacement. Motors with -62 or -65 designations

are open during crossover.

WARNING! IN SOME WINCH APPLICATIONS, OPEN

DURING CROSSOVER SPOOLS (-62 or -65) ARE NOT

RECOMMMENDED.

CLOSED DURING CROSSOVER SPOOLS

Closed during crossover spools do not allow port "A" to be

directly connected to port "B" when the spool is shifting

between full and partial displacement. Motors with -63 or -67

designations are closed during crossover. These motors

contain an internal factory preset relief valve. This valve

protects the motor during shifting only and is not a system

relief valve.

PILOT PRESSURE

A minimum of 100 PSI over case drain pressure is required to

shift the spool. The maximum allowable pressure to port "C" or

"D" is 3,500 PSI.

SHIFT ON THE RUN

The 15 Series Two Speed Motor may be shifted on the run

while loaded or unloaded.

MAXIMUM SPEED

Maximum rated speed is the same for either full or partial

displacement as stated in the performance data.

CASE DRAIN AND CROSS PORT LEAKAGE

The combined case drain and cross port leakage of the 15

Series Two Speed Motor is approximately 1 GPM per 1,000

PSI. This will vary with the oil viscosity.

OTHER INFORMATION

All other information as specified under Techinal Information

also applies to the 15 Series Two Speed Motor. (See page 5)

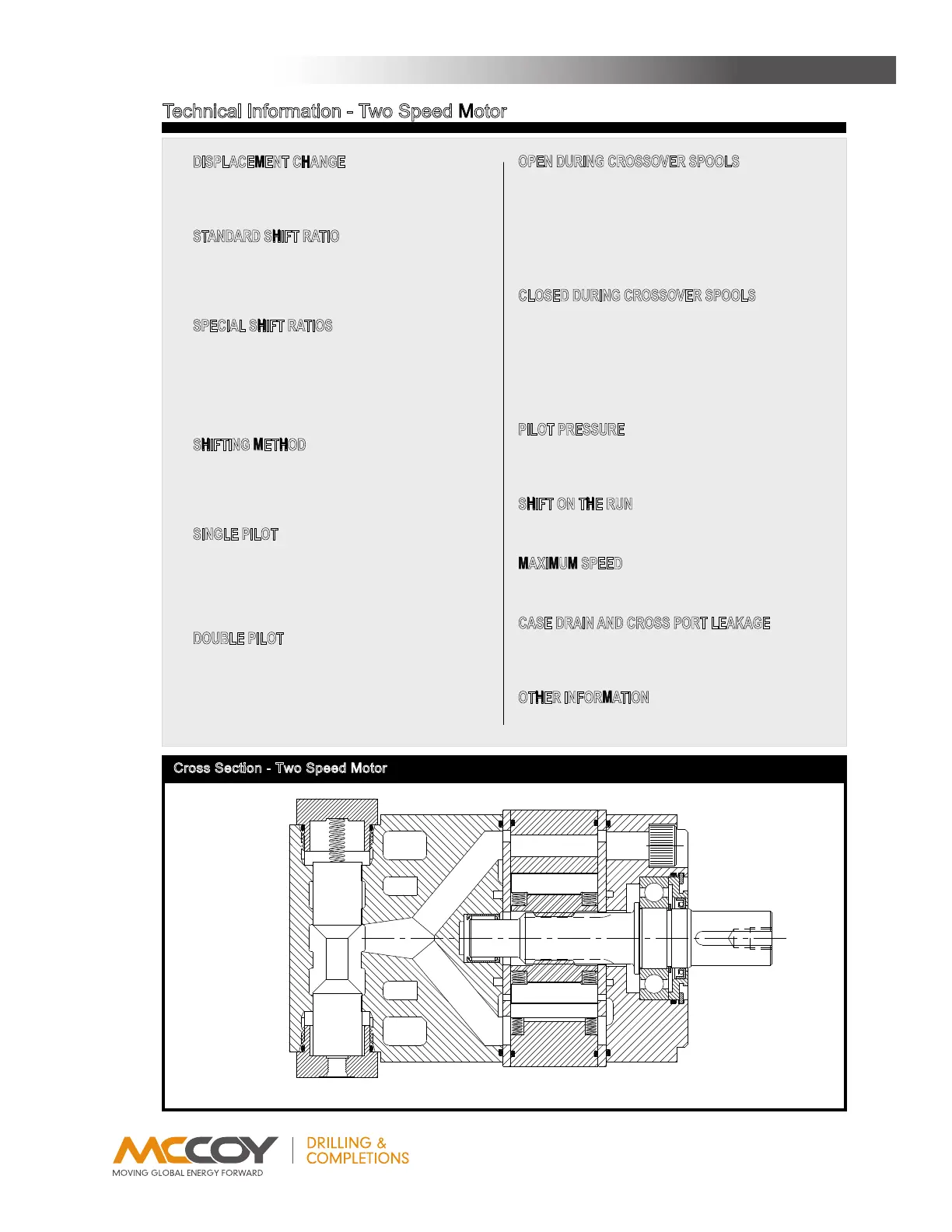

Cross Section - Two Speed Motor

Loading...

Loading...