4.2

hD8625 8-

5

/

8

” 35K Tong

Technical Manual

TroubleshooTing

B. RELIEF VALVE IS INCORRECTLY SET OR NOT FUNCTIONING

d. Re-establishhydraulicpowertoyourtong.Ensurethatnoequipmentfunctionsareactive.

e. Loosenthelockingnutonthepressurereliefvalve.

f. Openthetongdoortoactivatethesafetydoorsystemandinhibittongrotation.

g. Activatemotorcontrolvalve.Observethepressuredisplayedonthepressureindicator.Adjustthereliefvalveuntilthepressureindi-

catedisatthemaximumsystempressurespecifiedonthespecificationspage(maximumsystempressureisthepressureatwhich

yourtongachievesitsspecifiedtorque).

DO NOT ADJUST PRESSURE RELIEF TO A SETTING THAT ALLOWS HIGHER THAN MAXIMUM

SYSTEM PRESSURE. DOING SO CREATES A POTENTIAL FOR SERIOUS INJURY OR DEATH, AND

MAY CAUSE CATASTROPHIC EQUIPMENT FAILURE.

h. Releasethemotorcontrolvalveandtightenthelockingnutonthepressurereliefvalve.

i. Isolateyourtongfromhydraulicpower,anddepressurizefollowingtheprocedureinsection3.D.

j. Closethetongdoor,andremovethetemporarypressureindicator.Restorethesafetydoorpressuresupplylinetofactoryspecifica-

tions.Verifythatsafetydoorisoperatingcorrectly(seesection2.I.5.k).

Continued on next page

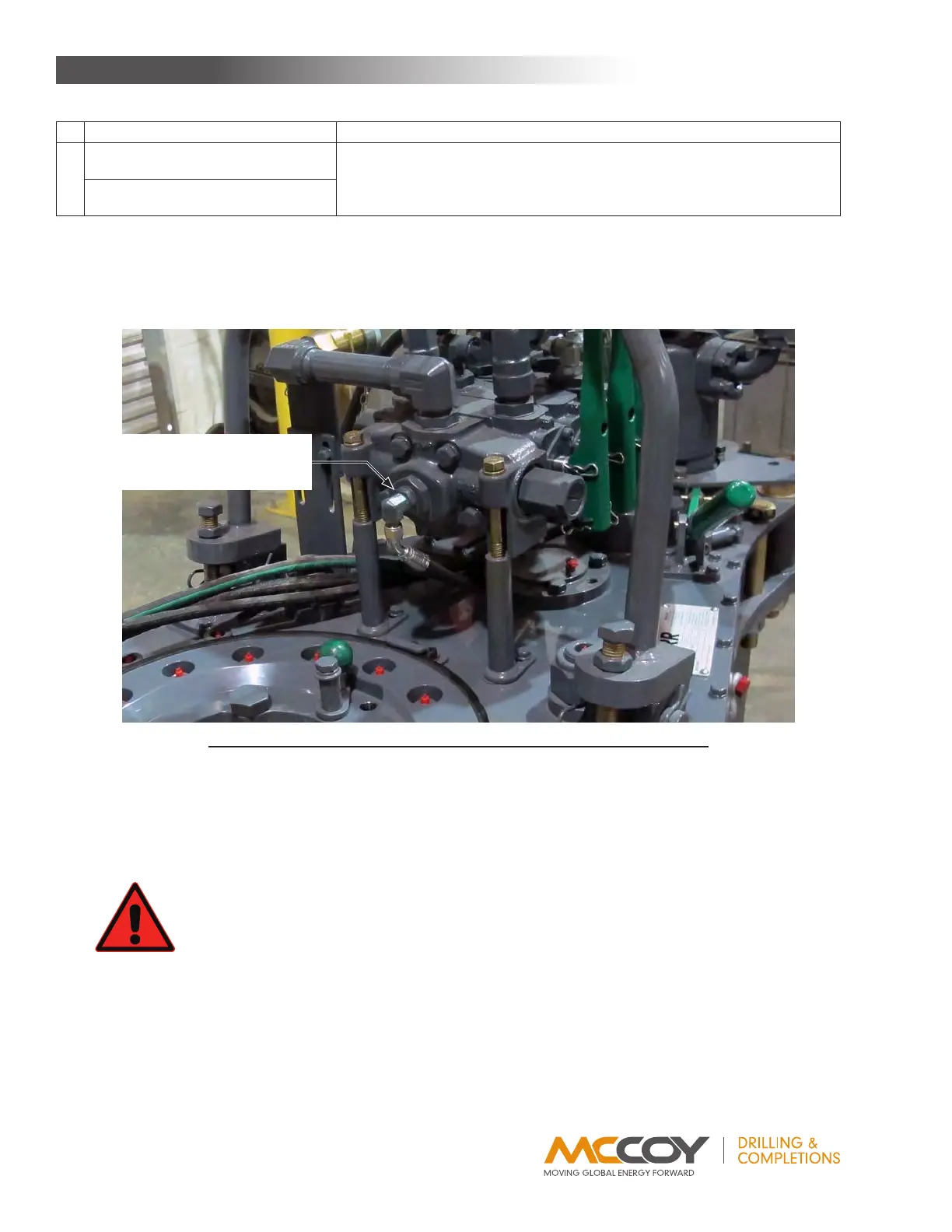

IllustratIon 4.B.1: relIef valve trouBlesHootIng - temPorary gauge InstallatIon

POSSIBLE PROBLEM SOLUTION(S)

1

Relief pressure set too low, resulting in

insufficienttongtorque

Adjustsetting(Seefollowingprocedure):

Relief pressure set too high, resulting in

crushedpipeorgeartrainfailure

a. Ifyourtongisequippedwithasystempressureindicatorproceedtostep“f”.Ifyourtongdoesnothaveasystempressureindicator,

atemporary0-3000PSIindicatormustbeinstalledonthehydraulicinlet.

b. Isolateyourtongfromhydraulicpower,anddepressurizefollowingtheprocedureinsection3.D.

c. Teeinatemporaryindicatoratthesafetydoorsupplypressureport.Ensureallhydraulicconnectionsareperformedbyaqualified

hydraulictechnician.

Connect a temporary 0 - 3000

PSI pressure indicator at this

location

Loading...

Loading...