2.2

hD8625 8-

5

/

8

” 35K Tong

Technical Manual

seTup & operaTion

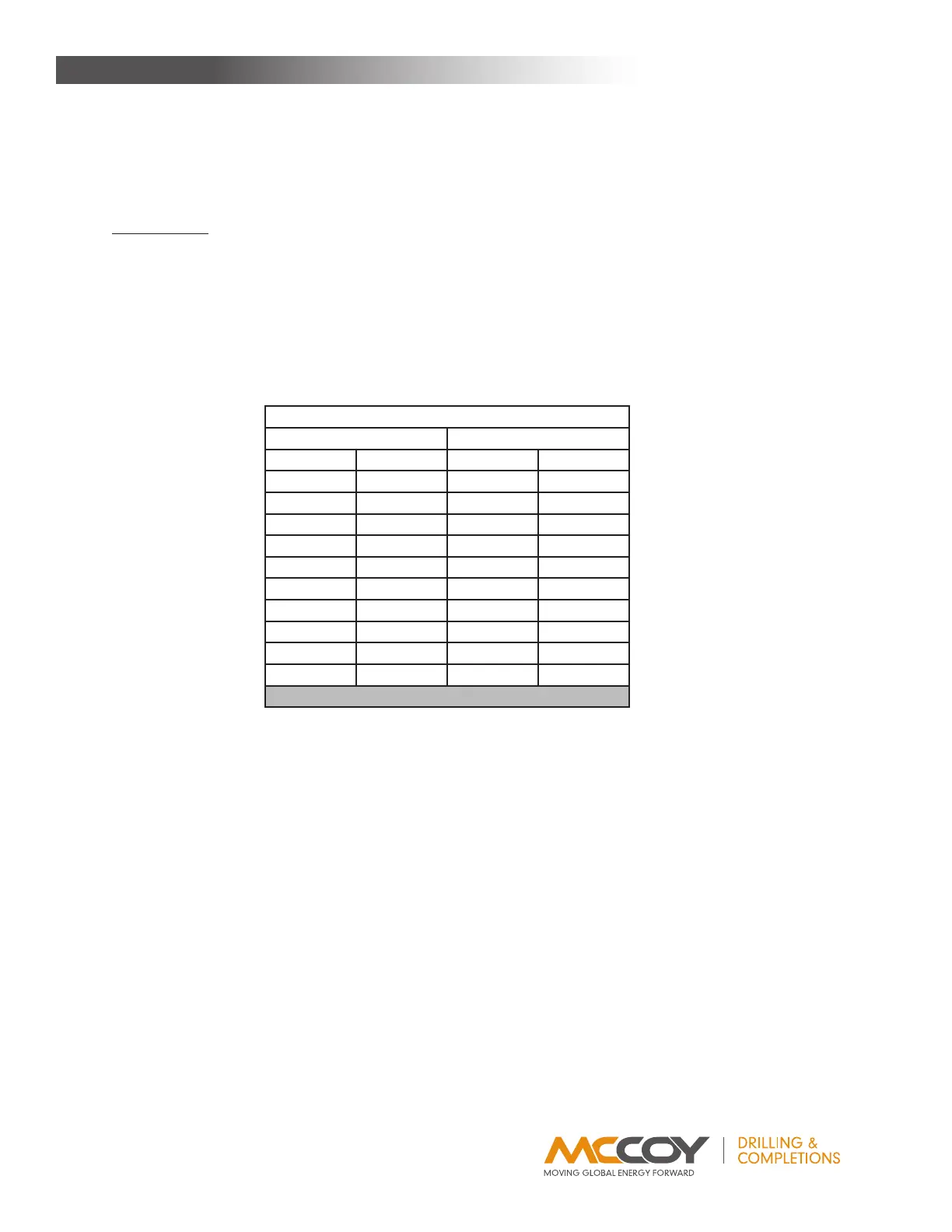

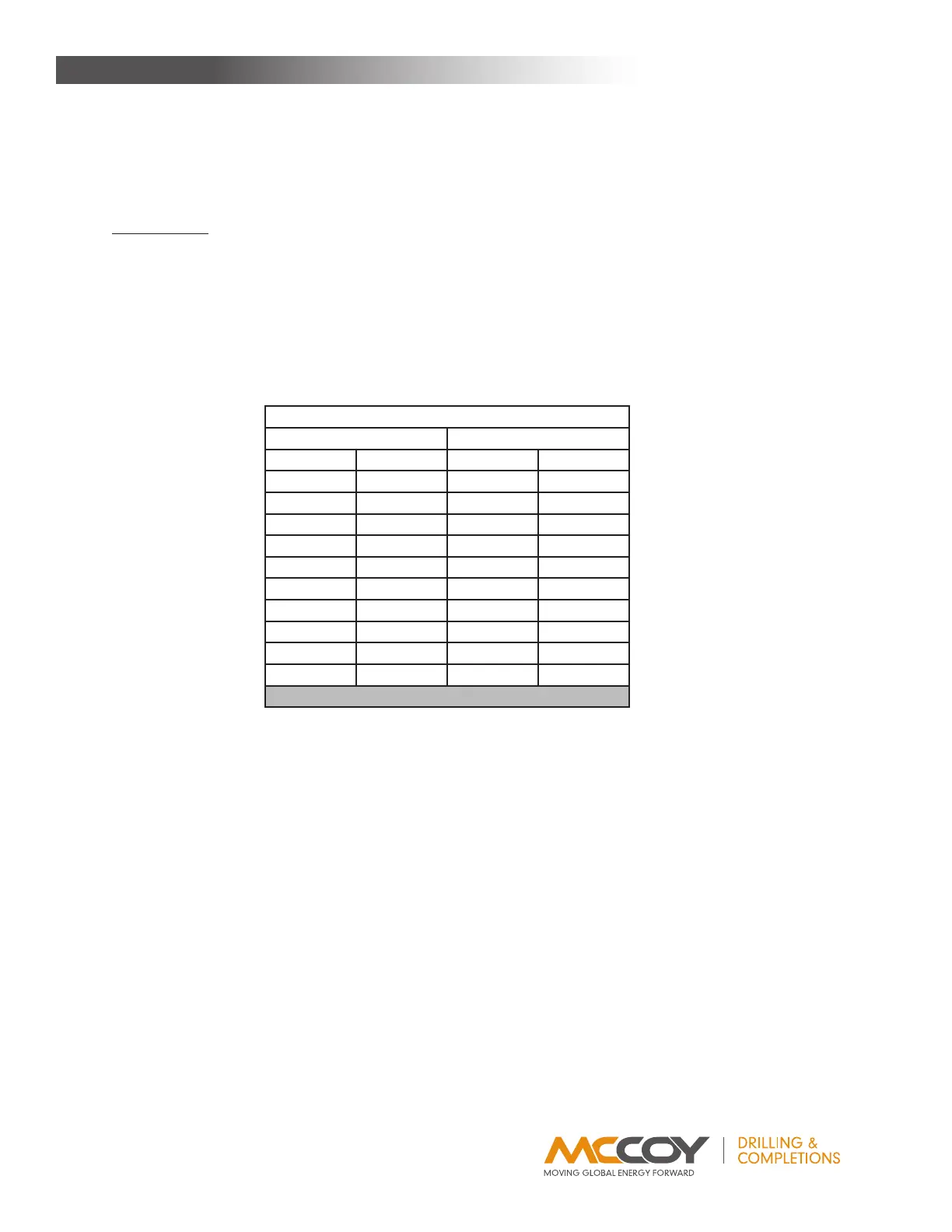

Minimum Allowable Chain Link Thickness at Any Point

Nominal Chain Size Minimum Thickness

Inches MM Inches MM

7/32 5.5 0.189 4.80

9/32 7 0.239 6.07

5/16 8 0.273 6.93

3/8 10 0.342 8.69

1/2 13 0.443 11.26

5/8 16 0.546 13.87

3/4 20 0.687 17.45

7/8 22 0.750 19.05

1 26 0.887 22.53

1-1/4 32 1.091 27.71

Refer To ASME B30.9

1. Inspection Of Slings

McCoy Drilling & Completions strongly recommends the following practices:

Acompleteinspectionofnewload-bearingdevicesandattachmentsshallbeperformedbyaqualified,designatedpersonpriorto

initialuse.Eachlinkandcomponentshallbeexaminedindividually,takingcaretoexposeandexamineallsurfacesincludingtheinner

linksurface.Theslingshallbeexaminedforconditionssuchasthoselistedintheremovalcriteriabelow.Inaddition,dailyinspection

ofslings,fasteningsandattachmentsshallbeperformedbyadesignatedperson.Ifdamageordefectsarefoundateitherinspection,

thedamagedordefectivecomponentshallbequarantinedfromserviceuntilitcanbeproperlyrepairedorreplaced.

RemovalCriteria:

Aload-bearingdeviceshallberemovedfromserviceifconditionssuchasthefollowingarepresent:

• Missingorillegibleslingidentification.

• Cracksorbreaks

• Evidenceoftamperingisseen-slingtaghasbeenmodifiedorobscured,ortamper-proofnutsaremissing.

• Signsofimpactonload-bearingcomponents,includingspreaderbars,liftinglugs,rigidslings&rigidslingweldments,andlegs&

legmounts.

• Brokenordamagedwelds.

• Excessivewear,nicks,orgouges.Refertothechartbelowtoensureminimumthicknessonchainlinkssuppliedisnotbebelow

thevalueslisted:

• Stretched,bent,twisted,ordeformedchainlinksorcomponents.

• Evidenceofheatdamage.

• Excessivepittingorcorrosion.

• Lackofabilityofchainorcomponentstohinge(articulate)freely.

• Weldsplatter.

• Forhooks,removalcriteriaasstatedinASMEB30.10

• Otherconditions,includingvisibledamage,thatcausedoubtastothecontinueduseofthesling.

Inspectalllugsandfixingpointsforsignsofelongationand/orbending,orformaterialbuild-uparoundthehole.Repairorreplace

componentsthatappeardistorted.Ensureall hardwareistightandingoodcondition. Replacemissinghardwareifnecessary.All

hardwaremustbefreeofrustandcorrosion.

Additionalinspectionsshallbeperformedduringslingusewhereserviceconditionswarrant.Periodicinspectionintervalsshallnot

exceedoneyear.Thefrequencyofperiodicinspectionsshouldbebasedon:

• Frequencyofuseoftheload-bearingdevice.

• Severityofserviceconditions

• Natureofliftsbeingmade

• Experiencegainedontheservicelifeofload-bearingdevicesusedinsimilarcircumstances.

Guidelinesfortheintervalare:

• NormalService-yearly

• SevereService-monthlytoquarterly

• SpecialService-asrecommendedbyaqualifiedperson

Loading...

Loading...