Technical Manual

hD8625 8-

5

/

8

” 35K Tong

2.23

2. Breaking A Connection

YOUR TONG SHOULD BE PROPERLY SUSPENDED, CONNECTED TO A HYDRAULIC POWER

SOURCE, AND READY TO BREAK CONNECTIONS.

a) Ensurehydraulicpowersupplytothetongisenergized.Themasterlinkontherigidslingmustbeusedtosuspendthetong.

Donotsuspendthetongdirectlyfromtherigidsling.SeeIllustration2.H.1.

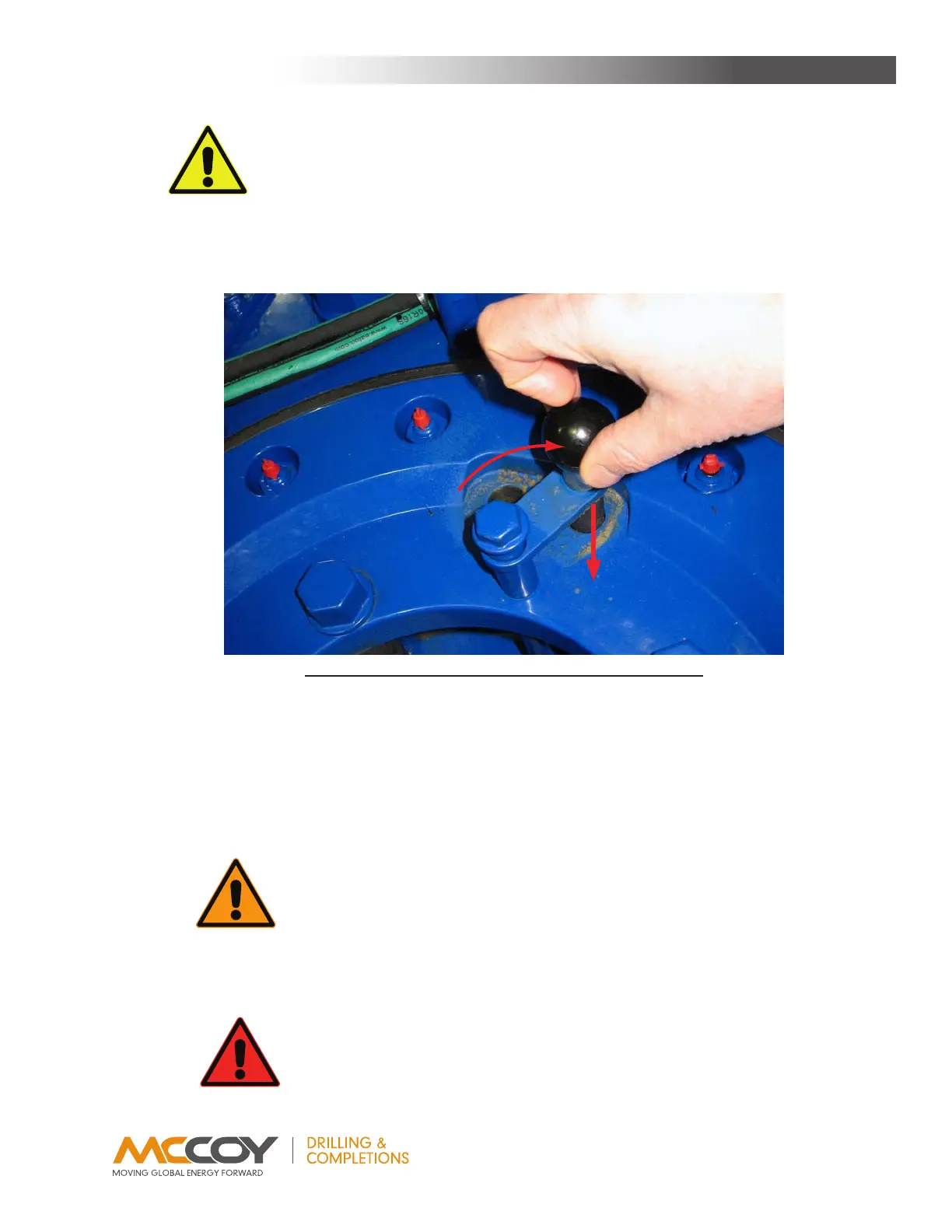

b) Setthebackingpinonthetong“breakout”operation.Liftuponthebackingpinandrotateittothe“breakout”position,whichis

2o’clockasseenfromthefrontofthetong.Theopeningintherotarygearmustbealignedwiththetongdooropeninginorder

toproperlysetthebackingpin(seeIllustration2.H.8).

IllustratIon 2.H.8: settIng BaCkIng PIn to “Break-out” PosItIon

c) Ensuretheloadcellisconfiguredforbreak-outoperation.Iftorquemeasurementforbreak-outisrequired,connecttheloadcell

totheoff-driller’sside(theright-handsideasseenfromtherearofthetong).

d) Connectsnublinestotherearofthetongtoarrestuncontrolledrotationoftheassembly.Thesnublinesmustberatedforthe

appliedtorquepluswhateversafetymarginsstatedbyyourownoperatingpolicies.Thesnublineconnectionpointsonthedrill

floormustbesturdyenoughtoabsorballappliedandpotentialforces.

e) Openthetongdoor(seeIllustration2.H.4).

f) Actuatetheliftcylindercontrolvalvetolifttheassemblyfromthedrillfloorifnecessary.Pullingthevalvetowardtheoperatorwill

retracttheliftcylindertolifttheassembly(seeillustration2.H.3).Notethatrigpersonnelarerequiredtostabilizethetongasit

isbeingliftedsoitdoesnotswingandcollidewithotherrigequipment.Movethetongontothestring.

RIG PERSONNEL MUST STABILIZE THE TONG AS IT IS LIFTED FROM THE DRILL FLOOR

g) Firmlyclosethetongdooragainstthelatchpost.

h) Rigpersonnelmayberequiredtostabilizethetongabovetheconnectionuntilthejawshavebeenclampedshut.

i) Break-outtorqueisonlyavailablewhentongmotorspeedissettolowspeedandtongisinlowgear.SeeSection2.G.2toset

tongtolowspeedandSection2.G.3toshifttolowgear.Donotshiftgearswhilethetongisrotating.

seTup & operaTion

SHIFTING TONG WHILE ROTATING THE MOTOR AND CAGE PLATE MAY RESULT IN

CATASTROPHIC GEAR TRAIN FAILURE

Loading...

Loading...