Technical Manual

hD8625 8-

5

/

8

” 35K Tong

4.1

TroubleshooTing

Adequatemaintenanceandproperfluidselectionisessentialforminimizinghydraulic-relatedfailures.Alltroubleshootingmustbeperformed

byatechniciantrainedinhydraulicsystems,andfamiliarwiththeequipmentdesign,assemblyandoperation.

Thefollowing troubleshootinginstructionsareintendedtobeguidelinesonly. Anyfaultsnotsolvedthroughtheuseofthisguideshouldbe

referredtoourengineeringdepartmentfortheirevaluationandrecommendations.

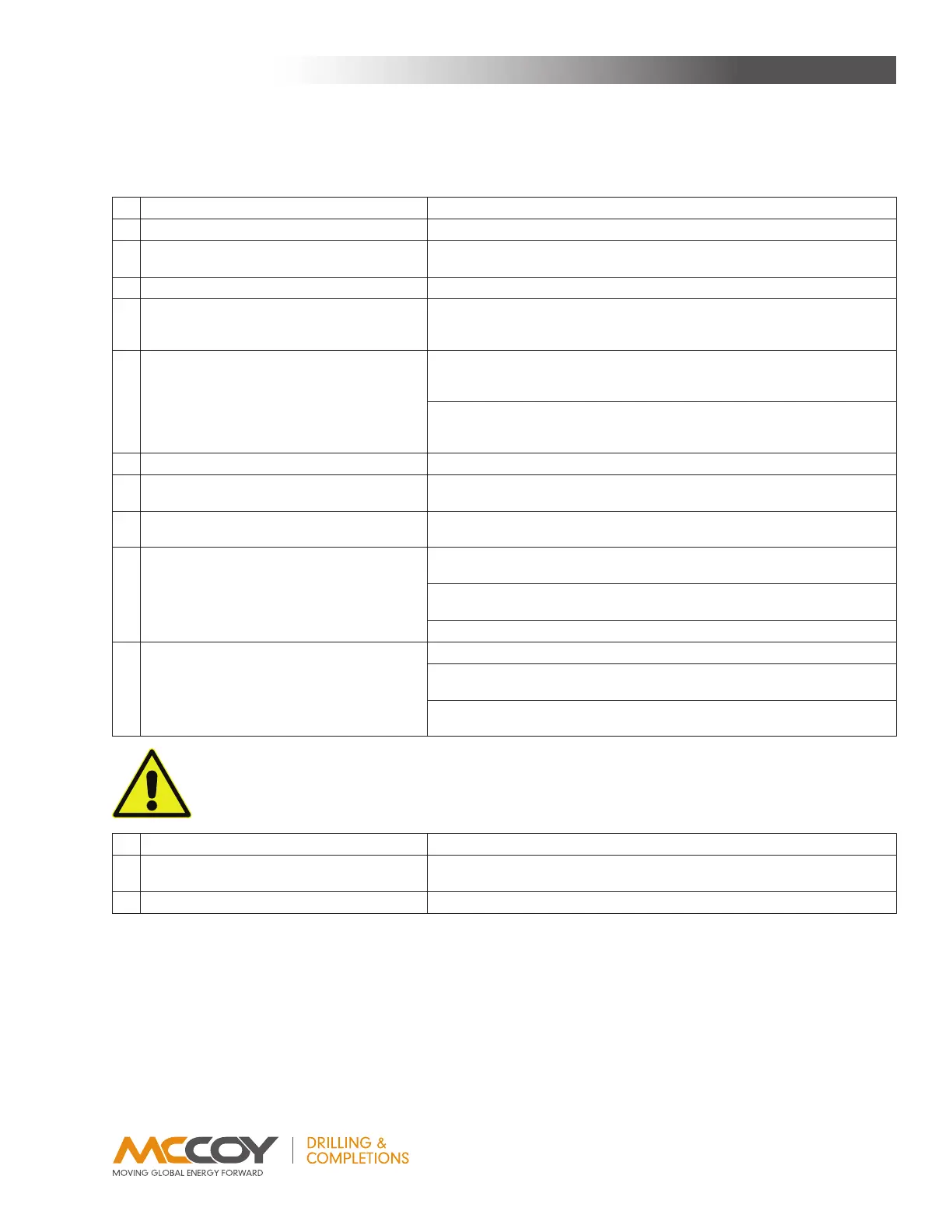

A. TONG WILL NOT DEVELOP SUFFICIENT TORQUE

MCCOY DRILLING & COMPLETIONS GUARANTEES CALIBRATION OF A LOAD CELL/TORQUE GAUGE

ASSEMBLY FOR A PERIOD OF ONE YEAR. MCCOY SUGGESTS THAT THE LOAD CELL/TORQUE

GAUGE ASSEMBLY BE RETURNED TO THE FACTORY FOR RE-CALIBRATION ON A YEARLY BASIS.

POSSIBLE PROBLEM SOLUTION(S)

1

Malfunctioningreliefvalveontonghydrauliccircuit SeeSection4.B,ReliefValveTroubleshooting

2 Directionalvalveisleaking

Checkdirectionalvalve.Neutralpositionshouldreturnfluiddirectlytothereservoir.

Replaceorrepairvalvetoensurecorrectoperation

3 Powerunitisnotproducingadequatepressure Troubleshootpowerunit(seeuser’smanualforyourparticularunit)

4

Poorhydraulicpressureatthe tong despiteade-

quate pressure at the power unit, or excessive

backpressureinthereturnline.

Restrictionsexistinlinebetweenpowerunitandtong.Inspectintegrityofself-seal-

ingcouplingstoensuretheyareallowingfullfluidflow.Checktoensurenoother

restrictionsexist(contaminatedcatchscreensorfilters,forexample)

5

Fluidviscosityisnotappropriate(too high or too

low)

EnsurehydraulicfluidbeingusedistheviscosityrecommendedbyMcCoyDrilling&

Completions.Powerunitpumpmaynotprimeiffluidistooheavy,andthehydraulic

systemwilloverheatiffluidistoolight.Replacewithproperviscosityfluid

Hydraulic fluid viscosity is affected by environmental conditions. Ensure the fluid

beingusedissuitableforhighorlowtemperatures.Replacewithproperviscosity

fluidfortheoperatingconditionsifnecessary

6 Wornordamagedtongmotorcausingslippage Replaceorrepairwornordamagedmotor

7

Damaged bearings or gears causing excessive

drag

Replaceorrepairwornordamagedgearsorbearings

8 Jawsslippingonpipe

Ensurejawdiesarenotworntothepointthattheycannotgrip.Ensurethecorrect

sizedjawsareinuse

9 Torquegaugeisindicatingincorrectly

Incorrectgauge is being used. Ensuregauge is the proper range,andhas been

properlycalibratedforthearmlengthoftheequipmentinuse

Gaugehasbeendamaged.Checkgaugeoperationandcalibrationonindependent

system

Gaugehasmistakenlybeenmarriedtoanincorrectloadcell

10 Loadcellismeasuringincorrectly

Incorrectloadcellisbeingused

Airistrappedintorquemeasuringcircuit(loadcell,hydraulicline,orgauge.Refer

totorquemeasurementtroubleshootinginSection6ofthismanual

Loadcellhasbeendamaged.Replaceloadcell,orreturntoMcCoyforrepairand

re-calibration

POSSIBLE PROBLEM SOLUTION(S)

11

Incorrectmotorspeedselected(appliesto2-speed

motorsonly)

Maximumtorque can only bedeveloped when LOW motor speed(maximum hy-

draulicdisplacement)isselected.

12 Incorrecttonggearselected MaximumtorquecanonlybedevelopedwhenLOWmotorgearisselected

Loading...

Loading...