2.14

hD8625 8-

5

/

8

” 35K Tong

Technical Manual

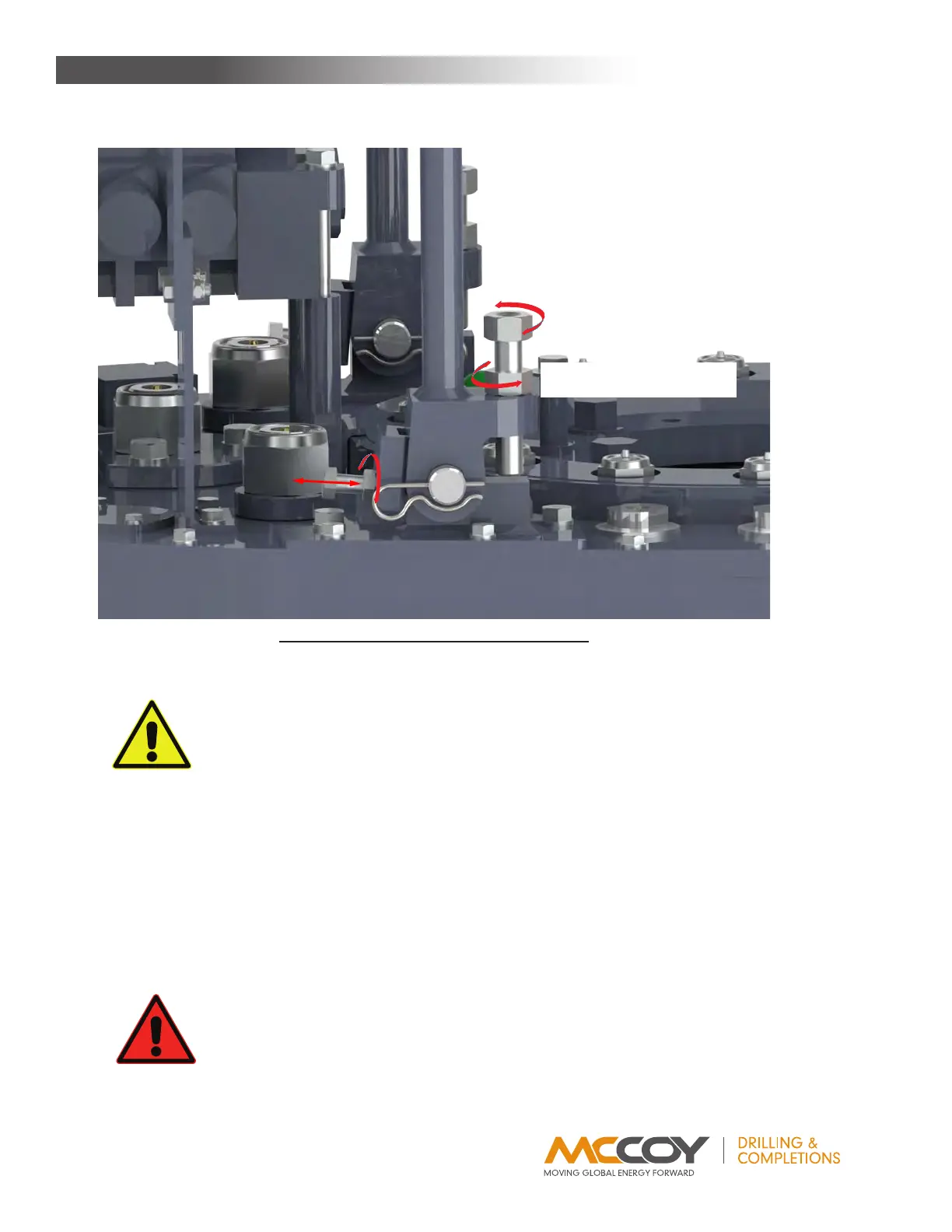

ii. Placealevellengthwise(fronttoback)alongthetong,ensuringthatitisparallelwiththesurfaceofthetong.Loosenthe1/2”

jamnutsontheadjustingboltsonrigidslingbrackets.Completelyloosentheadjustingbolts.Turneachadjustingboltequally

untiltonghangslevelfront-to-back.Lockadjustingboltsinplacewiththejamnuts.

IllustratIon 2.f.4: tong levelIng (front-to-rear)

McCoyDrilling&Completionsrecommendsthatthefollowingpre-operatingtestsbeperformedafterreceiptfromthefactoryorafter

extendedstorage,priortoreleasingthetongtooperations:

• Performacompleteinspectionofallfastenerstoensurenonehaveloosenedduringtransport.

• Connectthetongtothepowerunit,andapplyfullhydraulicpressure.Inspectandcorrectanyleaks.

• Operatethetongatfullspeedandinhighgearforadurationofone-halfhour.Hotbearingcapsmayindicateimpendingbearing

failure.

•

Switchtolowgearandoperateforanadditionalone-halfhouratfullspeed.

• Inspectall componentsandhydraulicfittings for possible defects following completion ofthetests.All Farr® Tongshavebeen

thoroughlytestedatthefactorypriortoshipping,butshippingdamagemustbeidentifiedbeforerunningthetonginanoperational

environment.

•

Carefullyinspectthesafetydoorcomponents,andtesttoensurethatthesafetydeviceoneachdoorisoperatingcorrectlybefore

releasingthetongtotheoperatingenvironment.

YOUR EQUIPMENT HAS BEEN THOROUGHLY TESTED AND INSPECTED AT THE FACTORY.

HOWEVER, WE ADVISE INSPECTION AND TESTING OF YOUR NEW TONG AFTER TAKING

POSSESSION IN ORDER TO ELIMINATE THE POSSIBILITY OF SHIPPING DAMAGE.

G. TONG OPERATION

1. Initial Start-up and Break-in Procedure

TONG DOOR MUST BE CLOSED AND SECURELY LATCHED BEFORE THE POWER UNIT IS

STARTED IN ORDER TO ASSURE THE SAFETY OF OPERATING PERSONNEL

seTup & operaTion

Loosen 1/2” hex jam nut be-

fore rotating adjustment bolt

Loading...

Loading...