Technical Manual

hD8625 8-

5

/

8

” 35K Tong

2.17

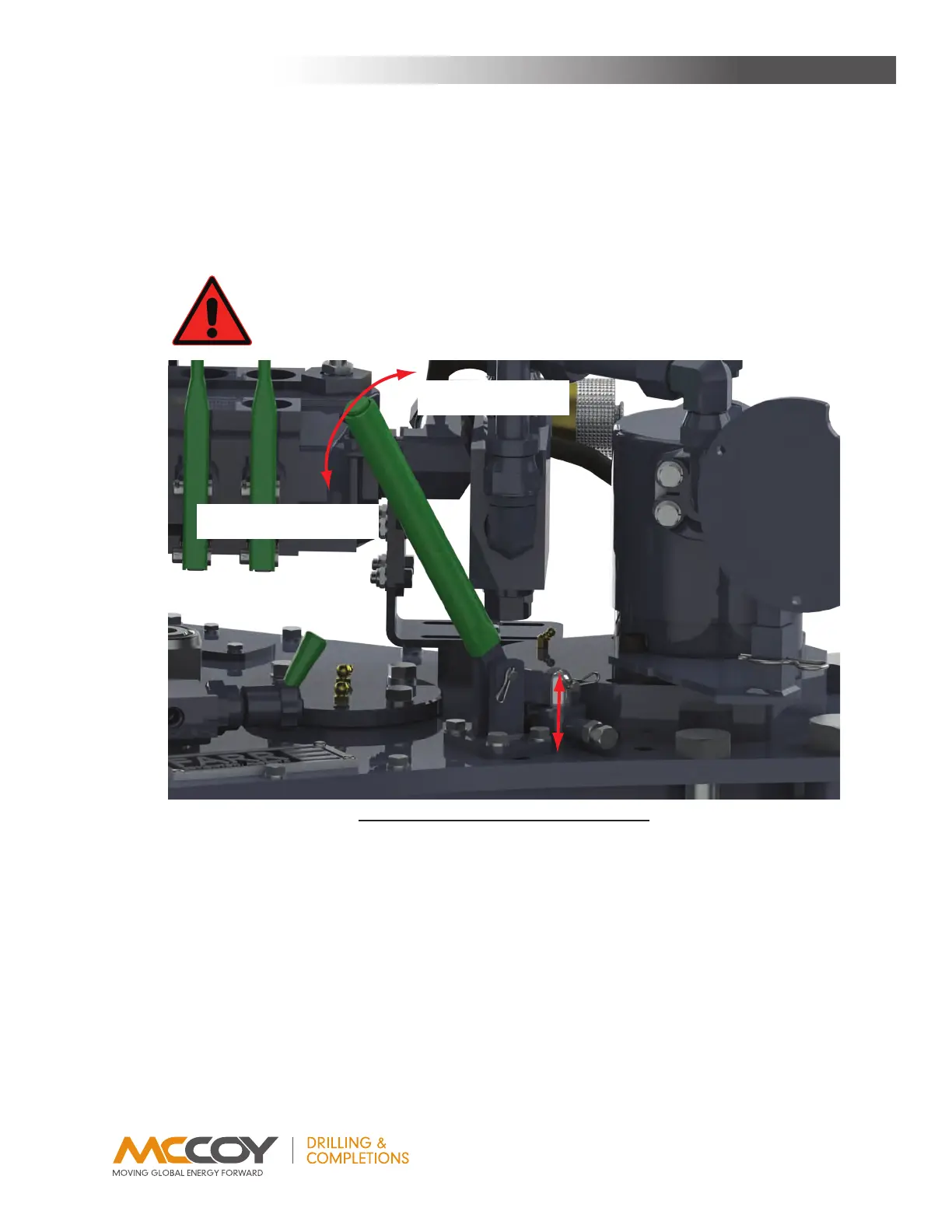

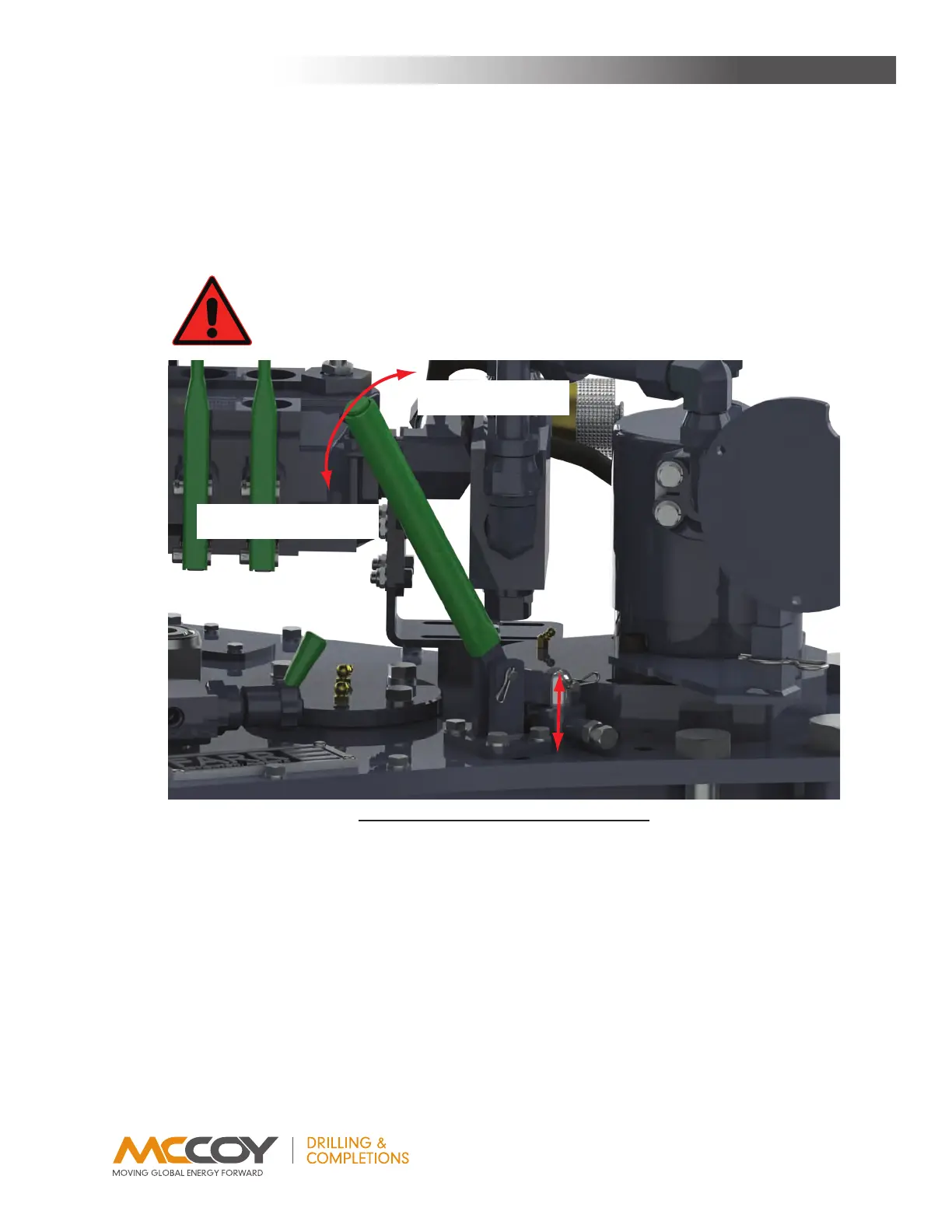

SHIFTING TONG WHILE ROTATING THE MOTOR AND CAGE PLATE MAY RESULT IN

CATASTROPHIC GEAR TRAIN FAILURE

IllustratIon 2.g.4: tong manual sHIft Control

4. General Comments

a) Positionrotarygearincontactwithbothidlergearswhenbreakingoutjointsorcollarswherehightorquesarerequired.

b) Whenmaking-upintegral(shouldered)joints,itisessentialtomakeupthelastturnofthethreadsinlowgear.Thisreducesthe

tendencyofaninstantstoporasuddenincreaseintorque,whichinducesextremelyhighstressesonthegeartrain.

c) DONOTemploythe“snapbreak”methodofbreaking-outjointswhenpullingastring.Bydefinition,the“snapbreak”methodis

aprocedureusedbysomeoperatorstobreakoutconnections,accomplishedbyleavingslackinthe“jaw-pipe”engagement,

andthenquicklypullingthethrottlevalvecontrolleverallowingthetongtosnapintoitsloadedorhightorquecondition.Although

thismethodisveryeffectiveinbreakingoutjoints,theextremelyhighstressplacedonthegeartrainfrequentlycausesgear

breakage.

seTup & operaTion

3. SHIFTING GEARS

Theshiftingshafthasthree“detent”positionsidentifyingthelowspeed/hightorqueposition,the“neutral”orfree-spinningposition,

andthehighspeed/lowtorqueposition.Thedetentstrengthmaybeadjustedbyreleasingthelocknutonthedetenttubeandincreas-

ingorrelaxingpressureonthedetentspring.Ensurethelocknutistightenedoncethedesireddetentpressurehasbeenset.

Toshifttothehigh-speedgear,movetheshiftinghandledownwardfromneutralposition.Toshifttothelow-speedgear,movethe

shiftinghandle upthroughtheneutraldetenttoitshighestposition.Notethat thehighclutchgearorthelowclutchgearmaynot

beexactlyalignedwhenshifting,sotheoperatormayneedto“bump”themotorcontrolhandleslightlytoturnthemainclutchgear

shaftandshiftingcollarintoalignment.Thisismosteffectivewhenapplyingasmallamountofpressureonthegearshiftleverinthe

directionyouwanttoshiftthetong,ensuringtheshiftingcollarwill“catch”whenthemainclutchgearalignswitheitherthehighor

lowclutchgear(seeIllustration2.G.4).

LIFT HANDLE TO

SHIFT TO LOW GEAR

PUSH HANDLE DOWN

TO SHIFT TO HIGH GEAR

Loading...

Loading...