Technical Manual

hD8625 8-

5

/

8

” 35K Tong

3.13

Assembly Procedures (continued...):

16. Installpiniongearshaft(PN997-A7-86B)intothesplineofthebottompiniongearandthelowerpinionbearing.

17. Slide2needlebearings(PN02-1404)overeachendoftheclutchshaft(PN997-HT-50),andpressupagainstcentregear.Slide

lowclutchgear(PN997-HT-52)overthebottomendoftheclutchshaft(thebottomendoftheclutchshaftcanbeidentifiedbythe

threadsforthegreasefittingmachinedintotheend)ontothetwoneedlebearings.Ensurethesmallerdiameterofthelowclutch

gearisdirectlyadjacenttothecentregearontheclutchshaft.Placelowerendofclutchshaftintothelowerclutchbearingthathas

beenpre-mountedinthelowerbodyplate.

18. Installshiftingcollar(PN997-HT-62)overthetopoftheclutchshaftandmeshwithlowclutchgearandthecentregearontheclutch

shaft.

19. Slidetheshiftingforkweldment(PN1050-72)overthebottom(threaded)endoftheshiftingshaft(PN1116-71)andsecurewitha

5/8”UNFhexnutand5/8”UNFhexjamnut.Placetheendoftheshiftingshaftinthelowershiftingbushing(weldedtothebottom

plate)andmeshtheshiftingforkwiththeshiftingcollar.

20. Installaretainerclip(PN02-0009)intothepinionidlergear(PN997-A2-119C).Pressanidlerbearing(PN02-0075)intothegear,

andsecurewiththesecondretainerclip.

21. Slidethepinionidlerhalf-shaft(PN1050-D5-105)throughthepinionidlergearassembly.Slidethebearingseal(PN02-0010)over

theendofthehalf-shaft,andsecuretothehalf-shaftwithashaftretainerclip(PN02-0008).

22. Placepinionidlerassemblies,lesstheidlerpadsandtopfasteners,ontopofthelowerpiniongearandplacethemasbestaspos-

sible-theirpositionmayhavetobeadjustedslightlyasthetopplateisattached(seeillustration3.H.2).

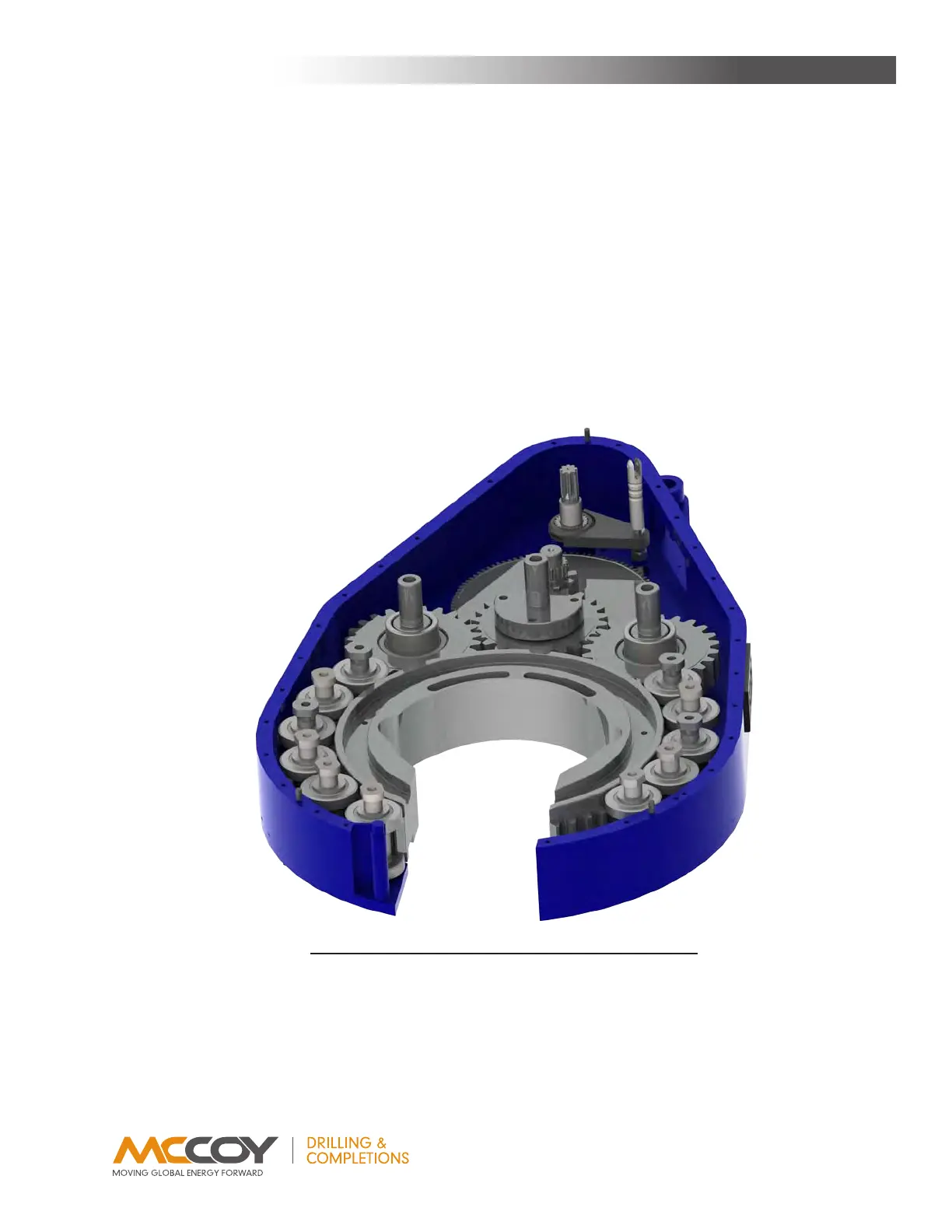

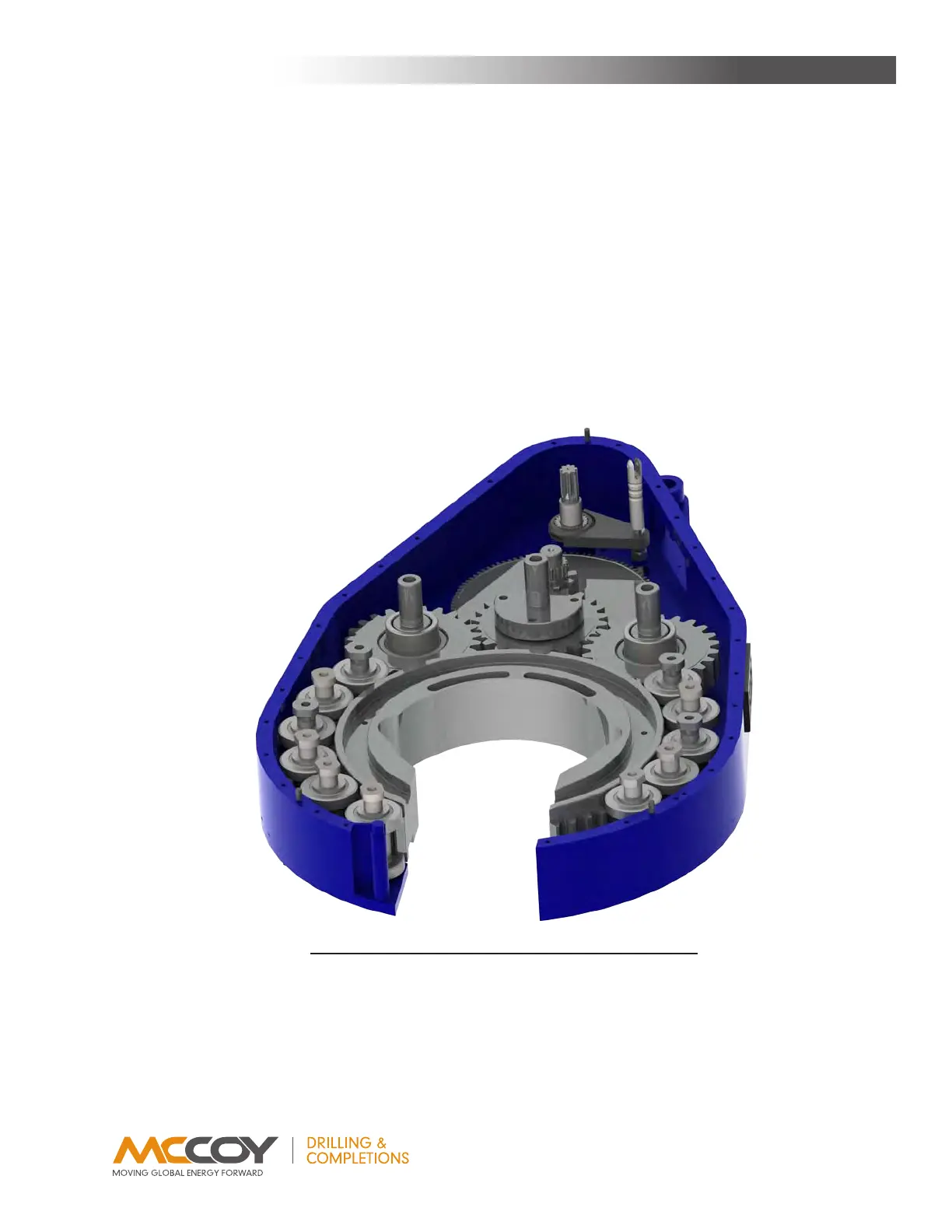

IllustratIon 3.H.2: tong assemBly - gear assemBly PosItIonIng

23. Thehigh piniongear(PN997-A4-87B)ismachinedwithshoulders aroundthecentresplineonbothsidesofthegear.Placethe

sideofthehighpiniongearwiththelargershoulderoverthetopofthesplinedpinionshaftandpressagainstthecentregearonthe

pinionshaft.

24. Installhighclutchgear(PN997-HT-51B)ontotheclutchshaft,ensuringthesmallerdiameterisdirectlyadjacenttothecentregear

ontheclutchshaft.

25. Carefullyremoveallsupportrollershafts,usingcautionnottoshiftthepositionoftheinstalledsupportrollerassembliesortodamage

thethreadsontheendoftheshafts.

MainTenance

Loading...

Loading...