6 Service functions and diagnostic messages

60 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

6.1.6 Monitoring of the motor

The motor controller CMMP-AS-...-M0 has the following protective functions for monitoring the motor

and the connected shaft encoder:

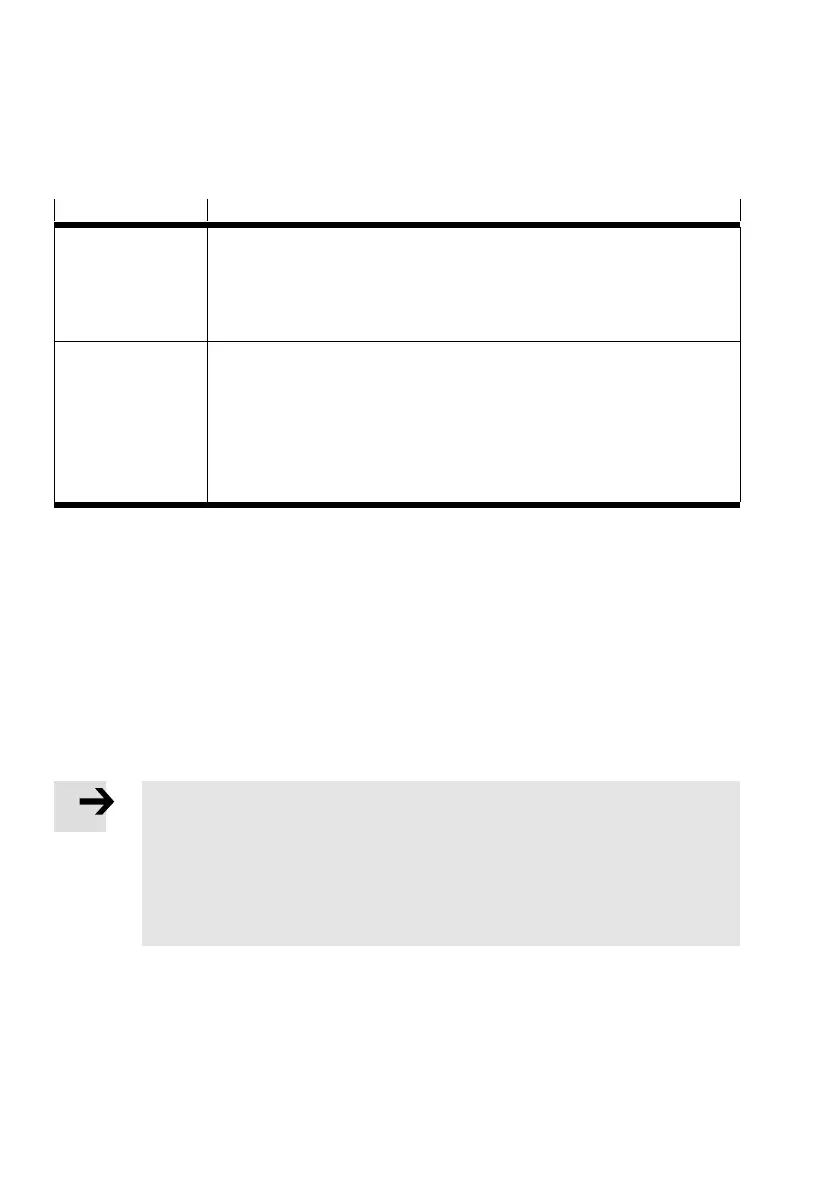

Protective function Description

Monitoring the shaft

encoder

An error of the shaft encoder results in switching off of the power output

stage. For the resolver, for example, the tracking signal is monitored. For in

cremental encoders, the commutation signals are checked. Generally true for

intelligent encoders is that their various error messages are evaluated and

reported to the CMMP-AS-...-M0 as common error E 08-8.

Measurement and

monitoring of the

motor temperature

The motor controller CMMP-AS-...-M0 has a digital and an analogue input for

recording and monitoring the motor temperature. They are selectable as tem

perature sensors.

– [X6]: Digital input for PTCs, N/C contacts and N/O contacts.

– [X2A] and

[X2B]:

N/C contact and KTY series analogue sensors. Other

sensors (NTC, PTC) require a corresponding software

adaptation as needed.

Tab. 6.1 Protective functions of the motor

6.1.7 I

2

t monitoring

The motor controller CMMP-AS-...-M0 has I

2

t monitoring to limit the average power loss in the power

end stage and in the motor. Since the power loss that occurs in the power electronics and the motor

can, in the worst case, grow at a rate equal to the square of the flowing current, the squared current

value is taken as a measure for the power loss.

6.1.8 Power monitoring for the brake chopper

The braking resistors are monitored on the firmware side through the function I

2

t brake chopper. When

the power monitoring “I²t brake chopper” of 100% is reached, the output of the internal braking resist

or is limited to the rated output.

Note

As a result of this switch-back, the error “E 07-0” “Overvoltage in the intermediate circuit” is

generated. If the braking process is not completed, the residual energy is fed back to the

motor controller and results in an uncontrolled running out of the drive if no automatic lock

ing mechanical system, clamping units or weight compensation is used.

This can result in damage to the machine. Connection of an appropriate clamping unit to

prevent an uncontrolled running out of the drive at the motor controller is recommended.

In addition, the brake chopper is protected by means of overcurrent detection. If a short circuit is detec

ted via the braking resistor, the brake chopper controller is switched off.

Loading...

Loading...