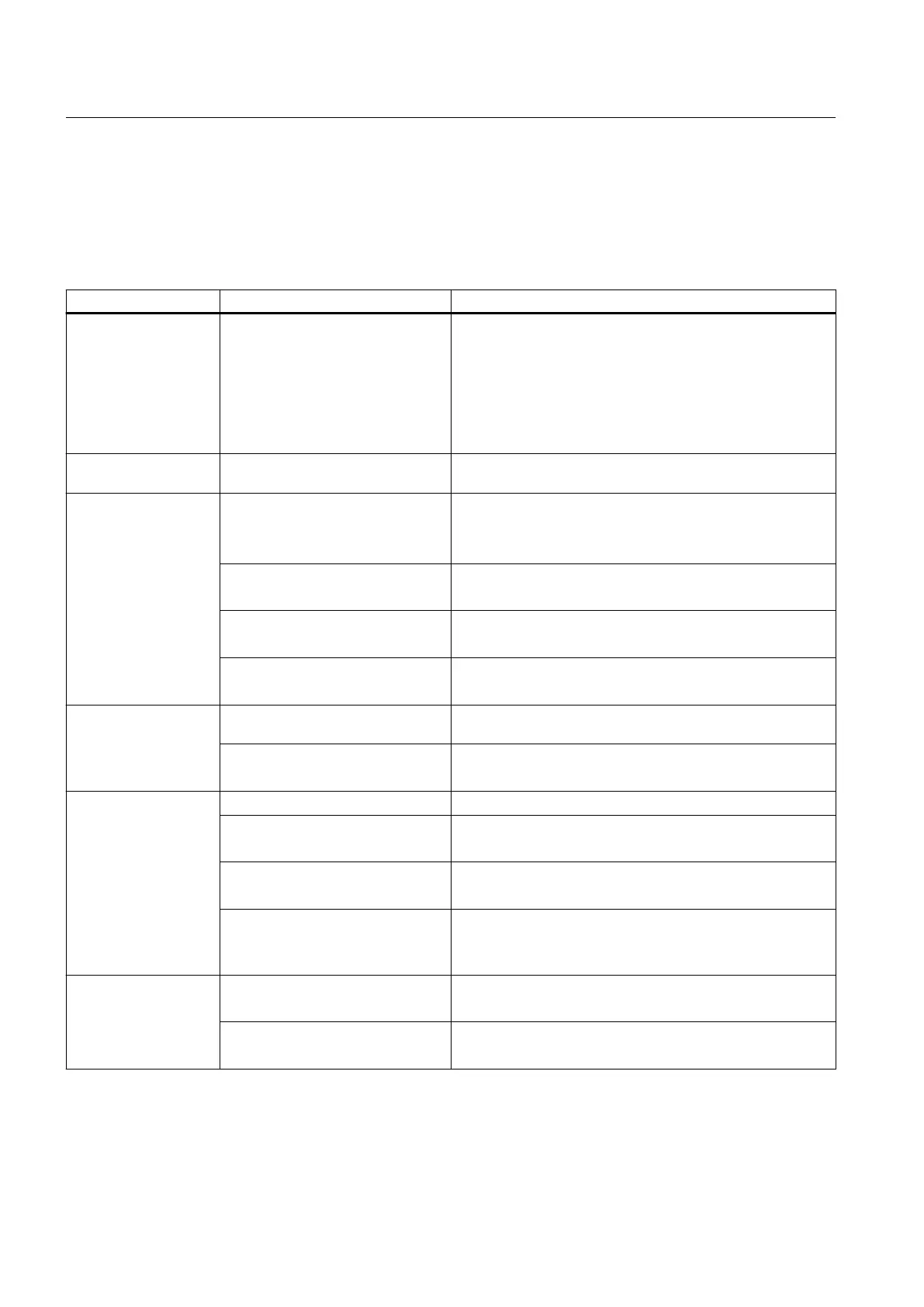

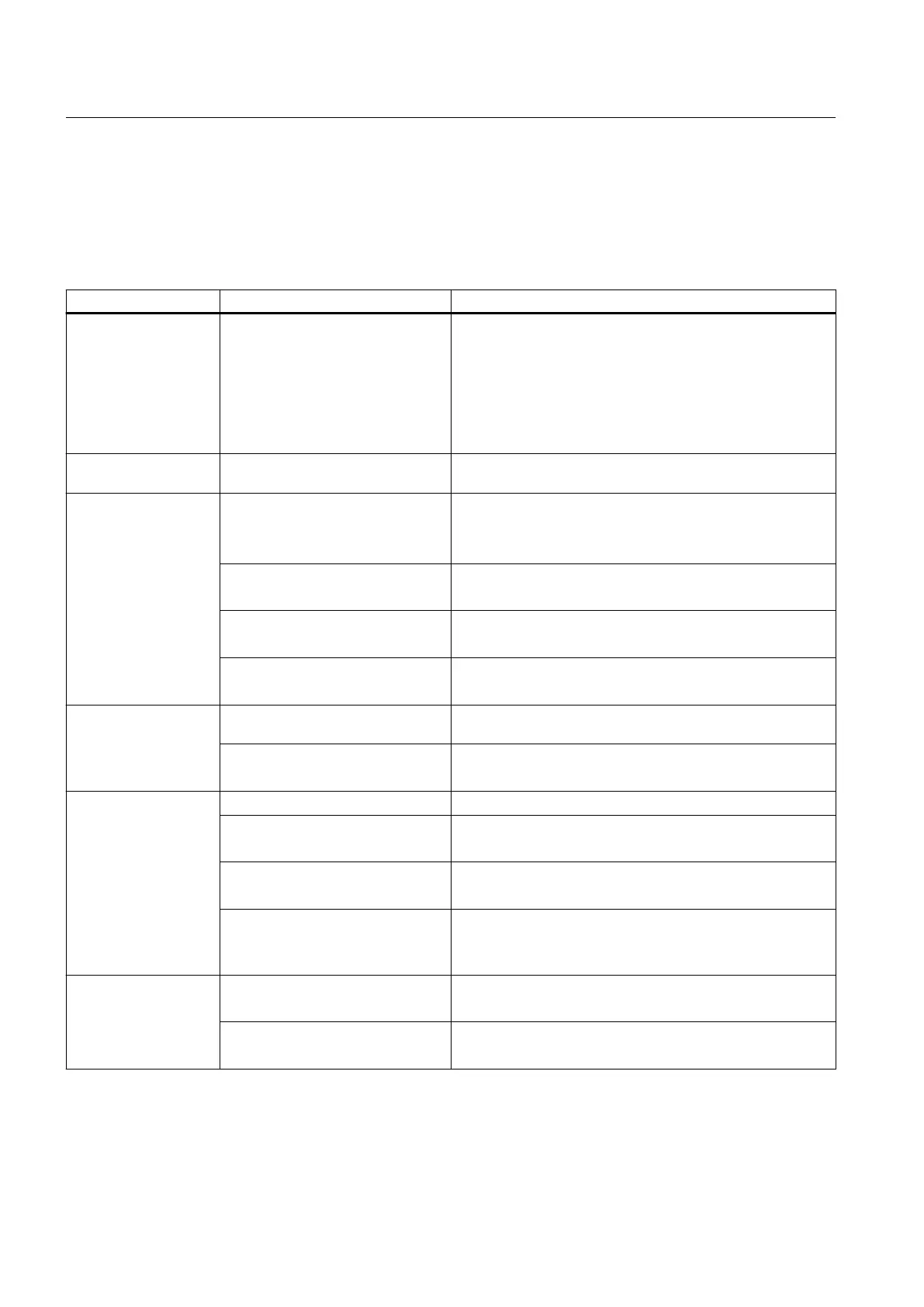

Possible faults and their rectification

The following table provides you with an overview of possible faults and indicates how they can

be rectified.

Table 8-2 Possible faults and their rectification

Possible faults Causes Possible remedies

Pressure monitor trig‐

gers an alarm

(For gear units with

pressure lubrication or

air‐oil cooler).

Oil pressure < 0.5 bar

● Check the oil level at room temperature

● Top up with oil if necessary

● Check the oil pump

● If required, replace the oil pump

● Check the oil filter and coarse filter

● If required, replace the oil filter or clean the coarse filter

Grease escaping at

the output shaft

Defective rotary shaft sealing rings

● Inspect the rotary shaft seals and replace if necessary

Noise

Damage to gearing

● Contact Customer Services

● Inspect toothed components

● Replace damaged components if necessary

The bearing play is excessive.

● Contact Customer Services

● Adjust bearing play

Defective rolling-contact bearings

● Contact Customer Services

● Replace defective rolling-contact bearings

Gear unit fastening has worked

loose

● Tighten bolts and nuts to the specified tightening torque

● Replace damaged bolts and nuts

Outer surface of gear

unit soiled with oil

Inadequate sealing of the housing

cover or joints

● Seal housing cover or joints

Labyrinth seals soiled with oil, incor‐

rect transport position

● Check oil filling

● Clean the labyrinths

Main drive motor does

not start

Motor direction of rotation incorrect

● Change polarity of motor

Backstop cage with sprags incor‐

rectly installed or defective

● Contact Customer Services

● Install the backstop cage, rotated through 180° - or replace

Overrunning clutch blocked

● Contact Customer Services

● Replace the overrunning clutch

Overrunning clutch cage with

sprags incorrectly installed and/or

defective

● Contact Customer Services

● Install the overrunning clutch cage, rotated through 180° -

or replace

Main drive motor can

start while the auxiliary

drive is operational

Defective electrical interlocking be‐

tween the main and auxiliary motor

● Check the connections

● If necessary, replace defective devices

Defective speed monitoring

● Check the connections

● If necessary, replace defective devices

Maintenance

8.4 Possible faults

REDUREX Gear unit 5200en

100 Operating Instructions 03/2019

Loading...

Loading...