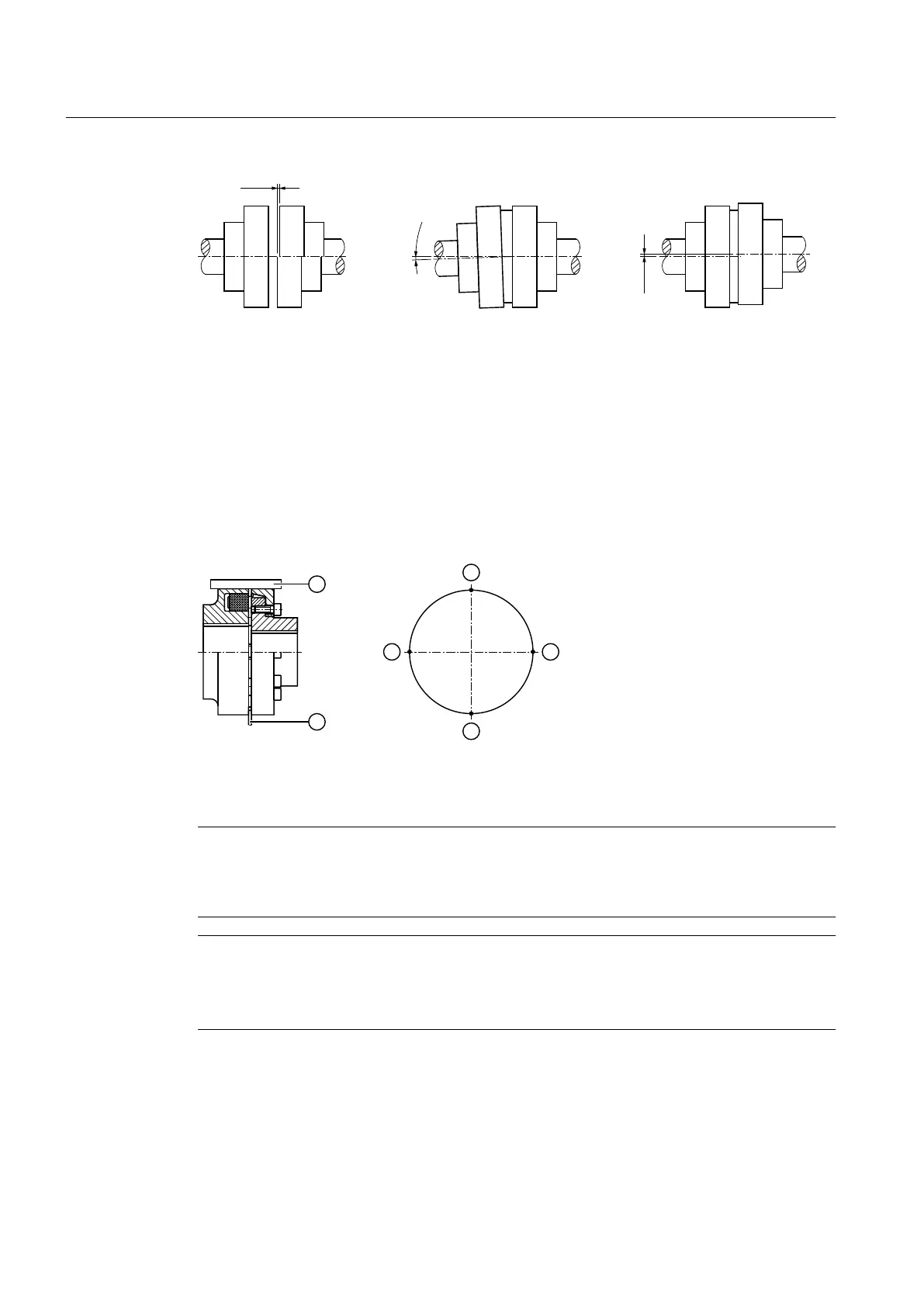

5DGLDOPLVDOLJQPHQW

˂.U

$QJXODUPLVDOLJQPHQW

˂.Z

/DWHUDOPLVDOLJQPHQW

˂.D

˂.D

˂.Z

˂.U

Figure 5-10 Possible displacements

Alignment

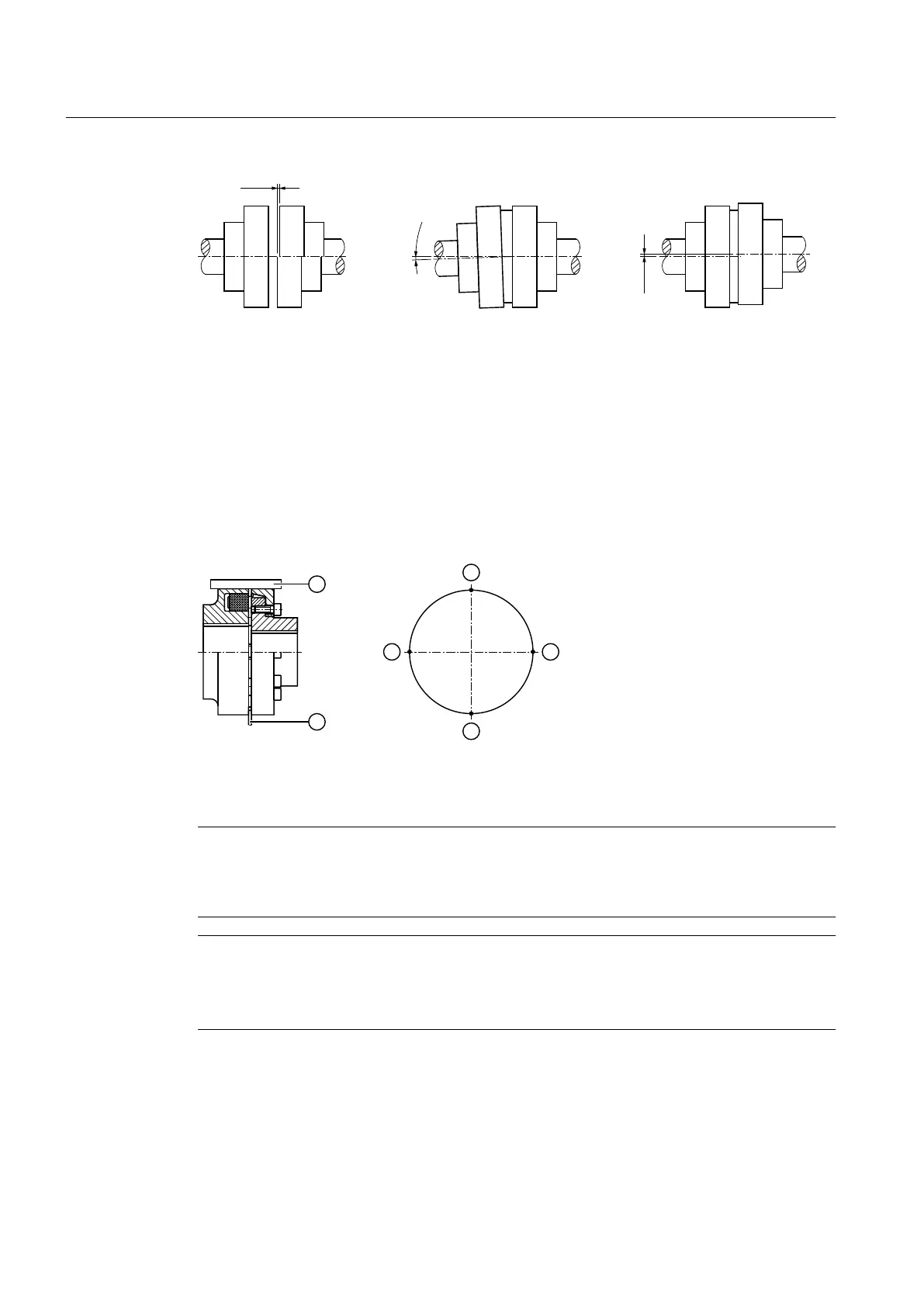

Alignment must be carried out in two axis planes that are vertical with respect to one another.

This is possible using rulers (radial offset) and feeler gauges (angular offset) as shown in the

diagram. You will achieve a greater degree of alignment accuracy by using a dial gauge or laser

alignment system.

The diagram below shows the alignment process based on the example of a flexible coupling:

① Ruler ③ Measuring points

② Feeler gauge

Figure 5-11 Alignment process based on the example of a flexible coupling

Note

It is advisable to insert shims or metal sheets under the mounting feet in order to align the drive

components in the vertical direction. It is helpful to use support paws with adjusting screws on

the foundation to adjust the drive components laterally.

Note

Gear unit with motor bell housing

Couplings do not have to be aligned if the gear unit and motor are connected through a motor

bell housing.

Further information

You can find additional information about the permissible alignment errors for Flender

couplings in the complete documentation for the gear unit.

Mounting

5.6 Couplings

REDUREX Gear unit 5200en

72 Operating Instructions 03/2019

Loading...

Loading...