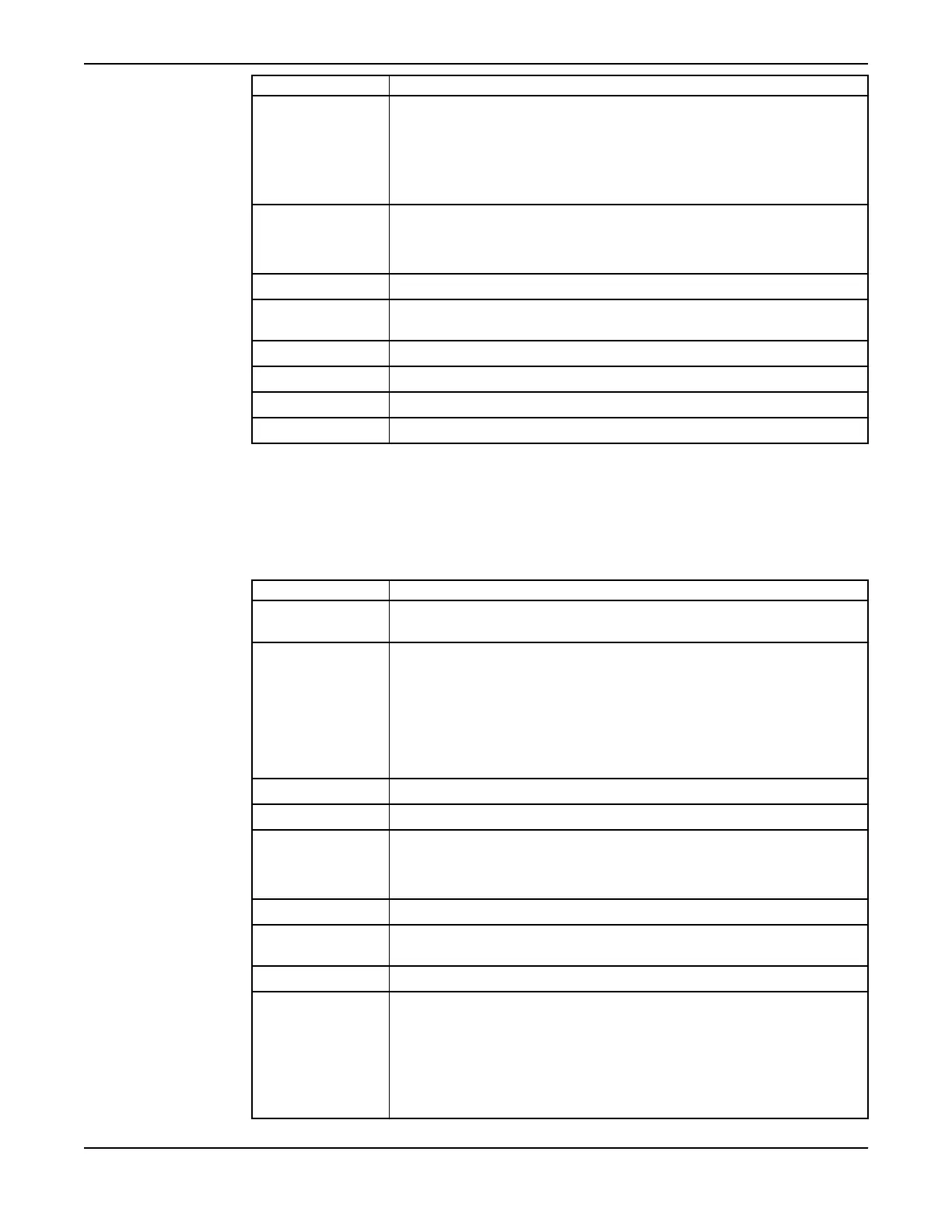

Part to service Action

Oil housing

1. Check the oil quality:

• If there is water in the oil, drain the oil and replace with new oil. After

one week of operation, check the oil quality again.

• If the oil is free from water, fill oil to the correct level, if necessary.

2. Replace the filling plug O-rings.

Hydraulic parts

1. Check the general condition of the impeller/propeller and the wear ring.

2. Replace if necessary.

3. If applicable, check the O-ring.

Zinc anodes Check and change if necessary.

Screw joints Check all externally accessible screw joints, and tighten if necessary to correct

torque. See Torque values (page 101).

Electrical cabinets Check that they are clean and dry.

Connection to power Check that the connections are properly tightened.

Level regulators Check the condition and function. See Check the leakage sensors (page 85).

Temperature sensors Check the condition and function. See Check the temperature sensors (page 84).

After any service involving the power connections, you must always check the rotation before operating

the pump. See Check the impeller rotation (page 77).

Major overhaul

1. Perform a complete inspection service. See Inspection (page 82).

2. Do these additional steps:

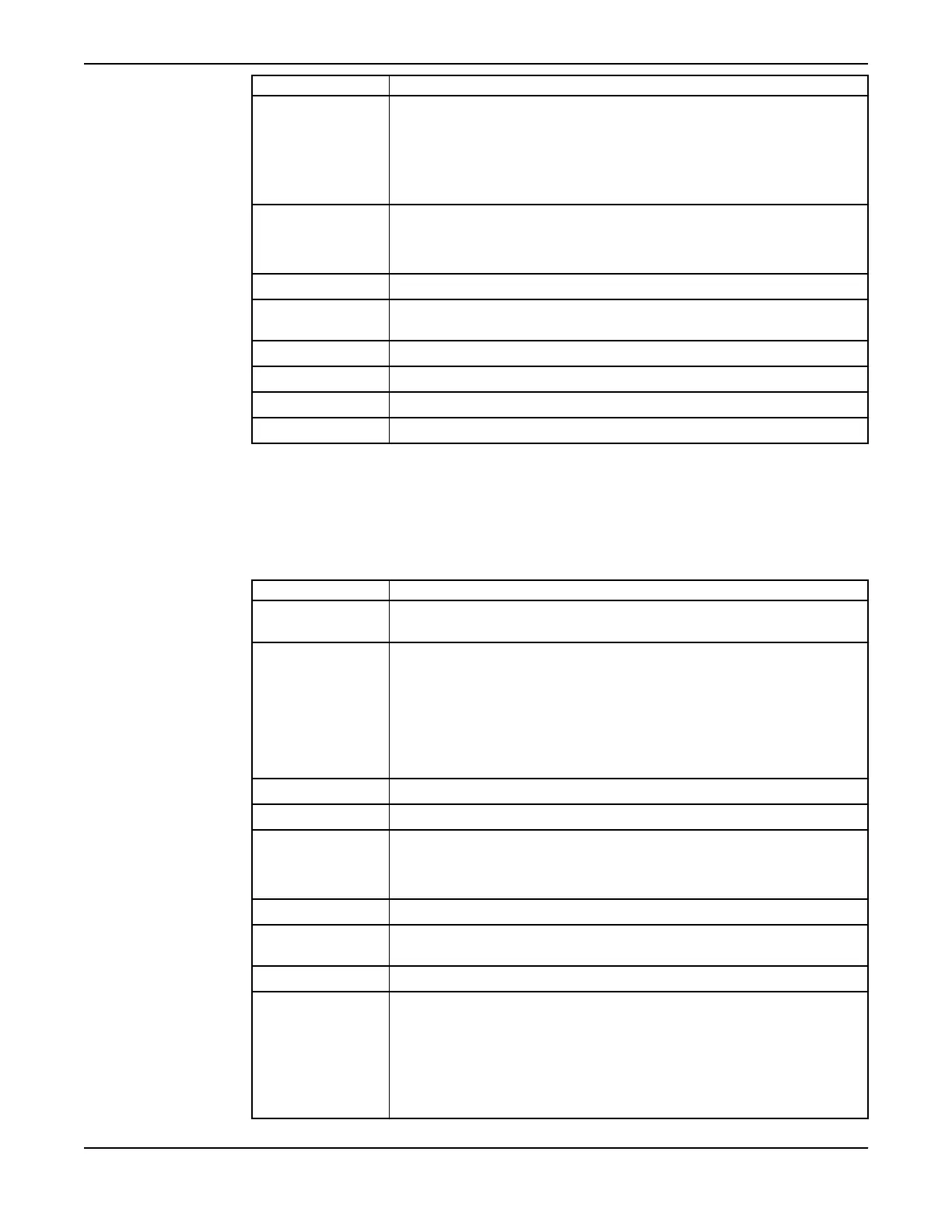

Part to service Action

Isolation check, drive

units up to 1.1 kV

Check that the resistance between earth and phase lead is more than 5 MΩ.

Isolation check, 1.2 –

6.6 kV drive units

1. Check that the resistance between earth and phase lead is above the

minimum for the motor voltage.

Recommended test voltage: 500 V DC (max. 1000 V DC).

The resistance value is related to motor voltage and should have minimum

value of 5 MΩ/kV at a temperature of 25°C (77°F).

For example, for a 6 kV motor the resistance between earth and phase lead

should be more than 30 MΩ.

Cable

Check that the rubber sheathing (jacket) is undamaged. Change if necessary.

Oil housing Change the oil.

General dismantling

and cleaning

1. Dismantle the pump completely.

2. Clean all the parts.

3. Re-assemble after replacing bearings, O-rings and seals.

Bearings Replace the bearings with new bearings.

O-rings and other

rubber sealing parts

Replace O-rings and other rubber sealing parts.

Seals Replace with new seals.

Sensors Check the following:

1. Stator temperature sensors.

2. Bearing temperature sensors.

3. FLS and CLS sensors.

See Check the temperature sensors (page 84) and Check the leakage sensors (page

85).

Maintenance

C3300/6x5, C/R3231, C3240, C3306, C3312, C3351, C3356, C3400, C3501, C3531, C3602, C3800 Installation,

Operation and Maintenance Manual

83

Loading...

Loading...