CLS

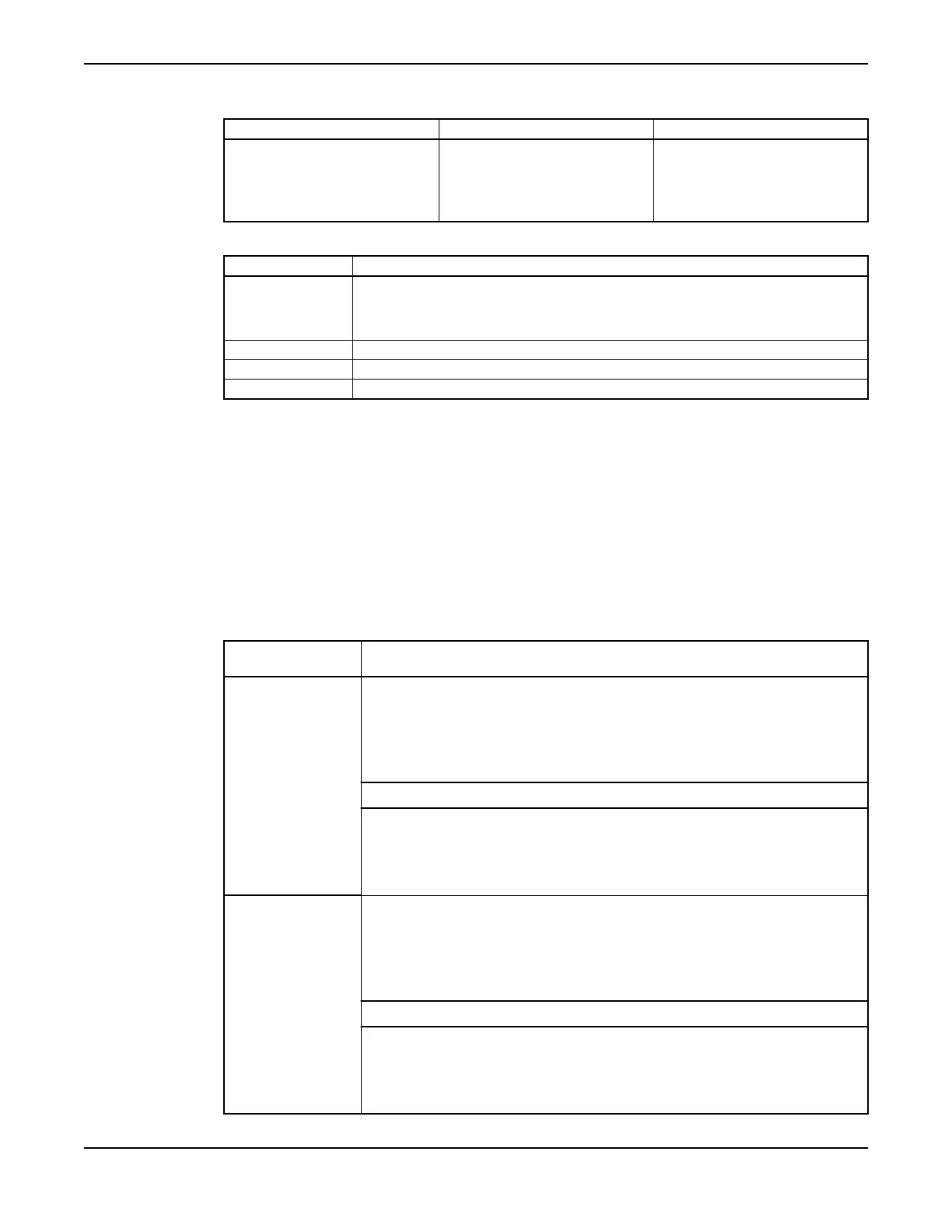

Table 8: Water-in-oil sensor (CLS)

Description Measured value Fault values

Capacitive leakage sensor located

in the oil housing. This sensor

issues an alarm if the water

content reaches a concentration of

approximately 30% or more.

Standard drive unit only.

CLS must be connected to 12 V

DC with correct polarity (+/–).

See table below.

Table 9: CLS current measurements

Measuring result Explanation

0 mA Can indicate one of the following conditions:

• The sensor has the wrong polarity. Check by changing plus and minus.

• The cable/lead is broken.

4.0 to 8.0 mA OK

27 to 33 mA Alarm current

> 33 mA Short circuit

Stator temperature monitoring methods

The purpose of stator-winding temperature monitoring is to make the motor shut off at high temperature.

There are several monitoring methods, depending on the voltage of the motor, and types of thermal

sensors chosen.

By using an analogue sensor, two adjustable alarm limits can be used, one for warning (“B”-alarm) and one

for pump stop (“A”-alarm). The configurations which may be used for monitoring the stator-winding

temperature depend upon the voltage range of the drive unit. See Drive units (page 21) for the voltage range

for each drive unit.

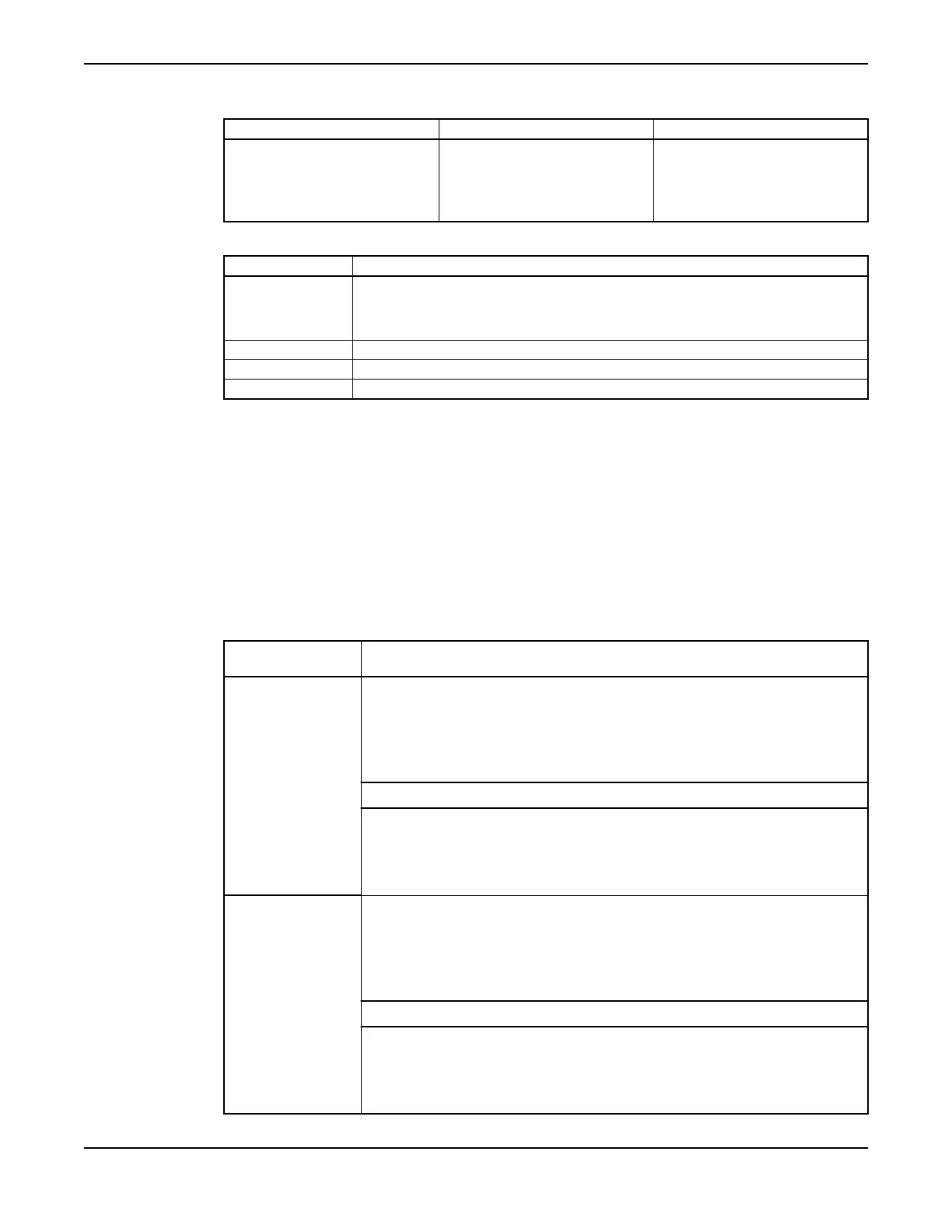

Up to 1.1 kV drive units

Table 10: Stator temperature monitoring configuration, up to 1.1 kV

Standard /

Optional

Monitoring Configuration Description

Standard This method uses the following configuration:

• Three thermal switches, connected in series, are incorporated in the coil ends

of the stator winding. The switches are normally closed, and open at 140°C

(285°F).

• One Pt100 sensor is incorporated in one of the windings.

Or:

This method uses the following configuration:

• Three thermistors, connected in series, are incorporated in the coil ends of the

stator windings. T

Ref

=140°C (285°F).

• One Pt100 sensor is incorporated in one of the windings.

Optional

This method uses the following configuration:

• Three thermal switches, connected in series, are incorporated in the coil ends

of the stator winding. The switches are normally closed, and open at 140°C

(285°F).

• Three Pt100 sensors, one for each phase, are incorporated in the windings.

Or:

This method uses the following configuration:

• Three thermistors, connected in series, are incorporated in the coil ends of the

stator windings. T

Ref

=140°C (285°F).

• Three Pt100 sensors, one for each phase, are incorporated in the windings.

Product Description

C3300/6x5, C/R3231, C3240, C3306, C3312, C3351, C3356, C3400, C3501, C3531, C3602, C3800 Installation,

Operation and Maintenance Manual

31

Loading...

Loading...