Redwood Global Ltd - ST6D42

Operator and Maintenance Manual

Chapter 5: Maintenance

5.6 AFTERTREATMENT SYSTEM

5.6.1 DIESEL PARTICULATE FILTER (DPF)

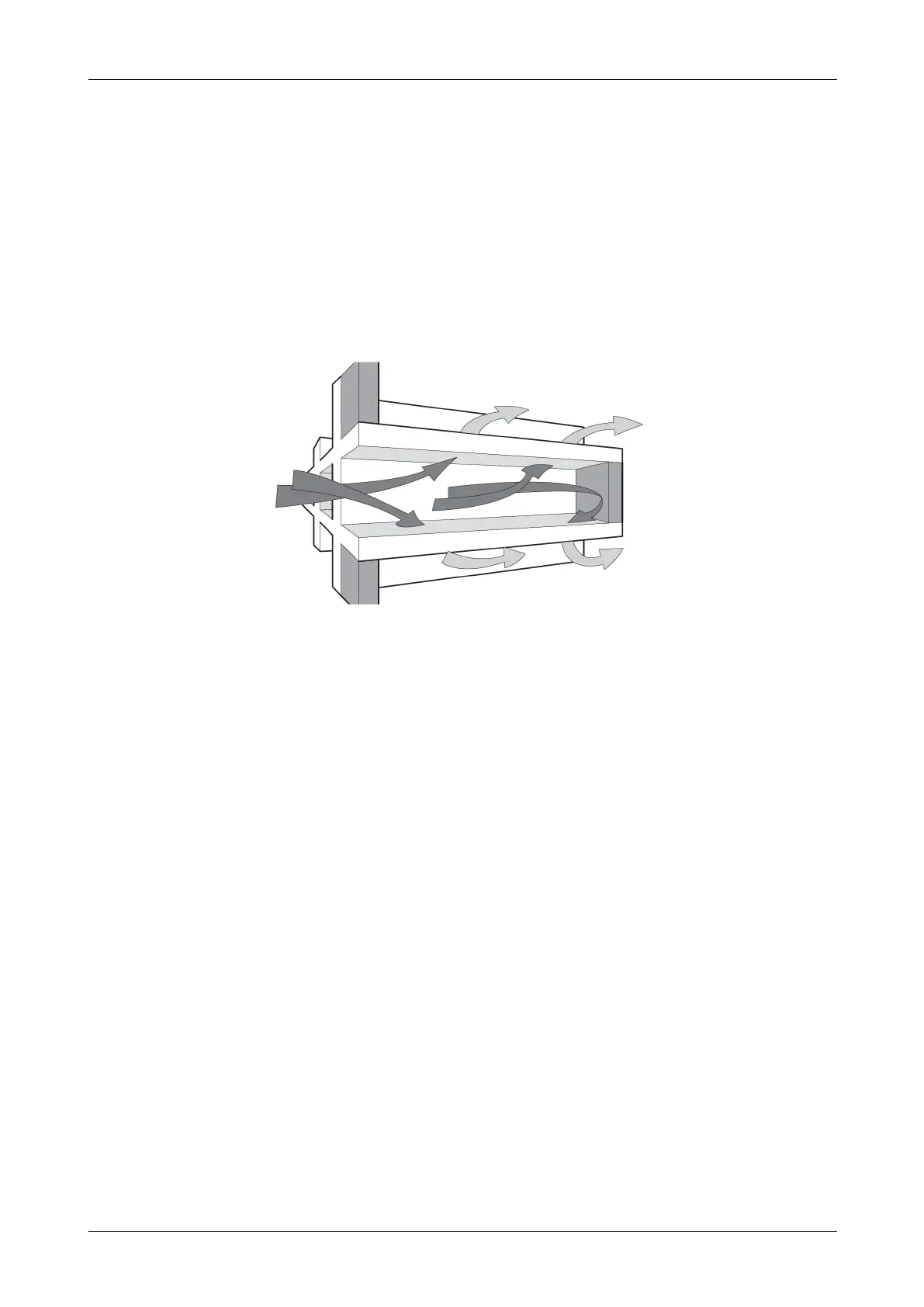

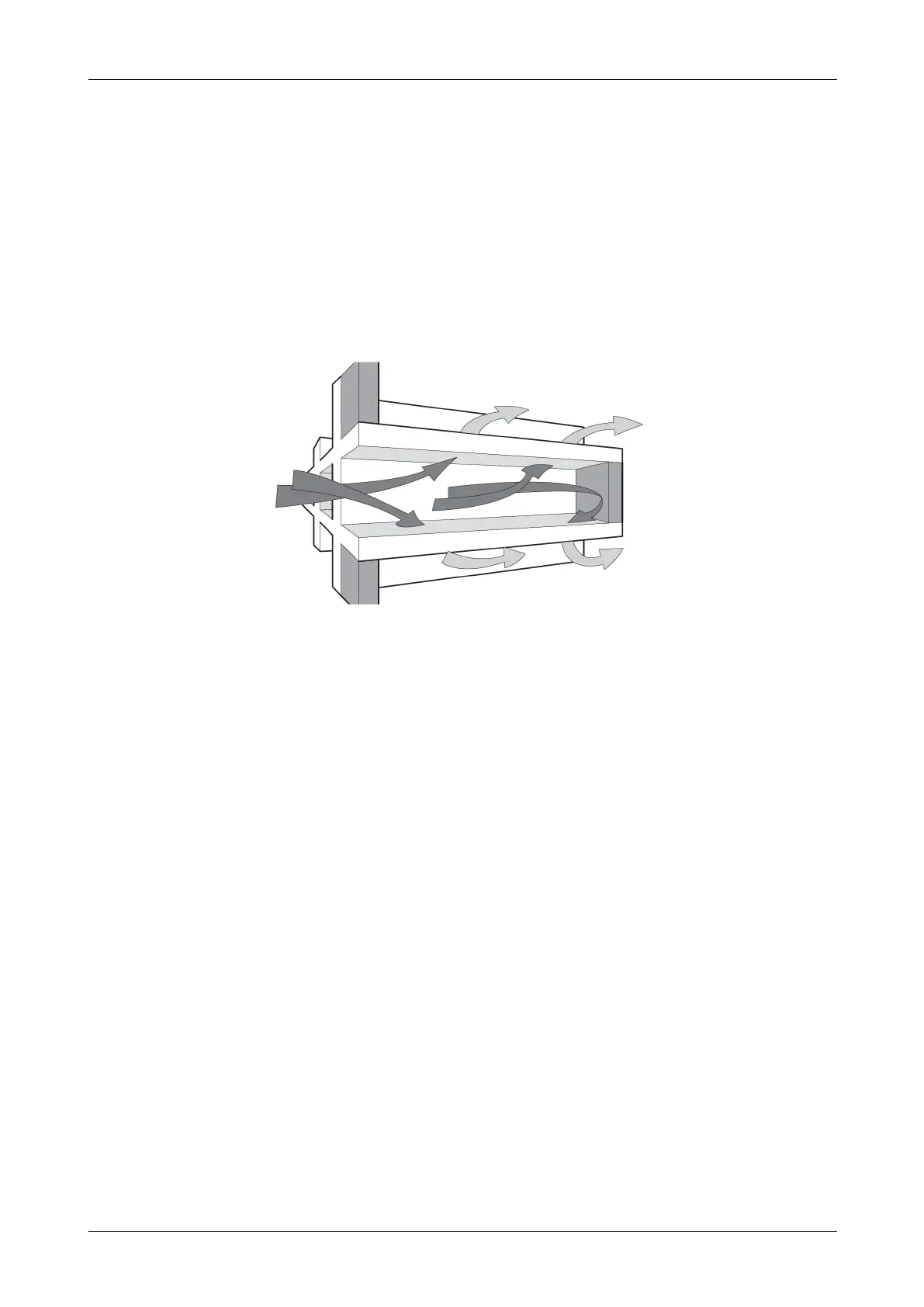

The DPF (Diesel Particulate Filter) system serves to prevent particulate matter (PM) in

emissions from being discharged into the air and consists of a DPF body, one exhaust

gas temperature sensors, and one differential pressure sensor. The DPF is composed of a

porous wall capable of filtering out particulate matter. As exhaust gas pass through the

DPF to the SCR system. Following this, PM collected from the DPF is eliminated using a

suitable regeneration method.

Figure 47 - DPF (Diesel particulate filter)

5.6.2 DPF REGENERATION

The DPF serves to filter out soot and ash, a contaminant found in the emissions of Diesel

engines. An excessive build-up of soot in the DPF leads to issues such as a drop in engine

power due to increased back pressure in the engine, making it crucial to perform

regeneration in order to eliminate PM in the DPF. The ECU (Engine Control

Unit)calculates the amount of exhaust smoke using the signal from the DPF differential

sensor, the vehicle operating time, the vehicle fuel consumption and engine simulation

data. Once this amount reaches a certain level, the ECU performs DPF regeneration.

Regeneration involves burning accumulated PM, it increases the temperature

upstream of the DOC (Diesel Observation Catalyst) by means of adjustment to the

engine throttle and near post injection, as well as raising the DPF temperature higher

than the exhaust combustion temperature (580

o

or higher) to burn exhaust gas by

means of far post injection. After DPF regeneration, only ash remains in the DPF.

12-00-004 v2.1 88

Loading...

Loading...