32

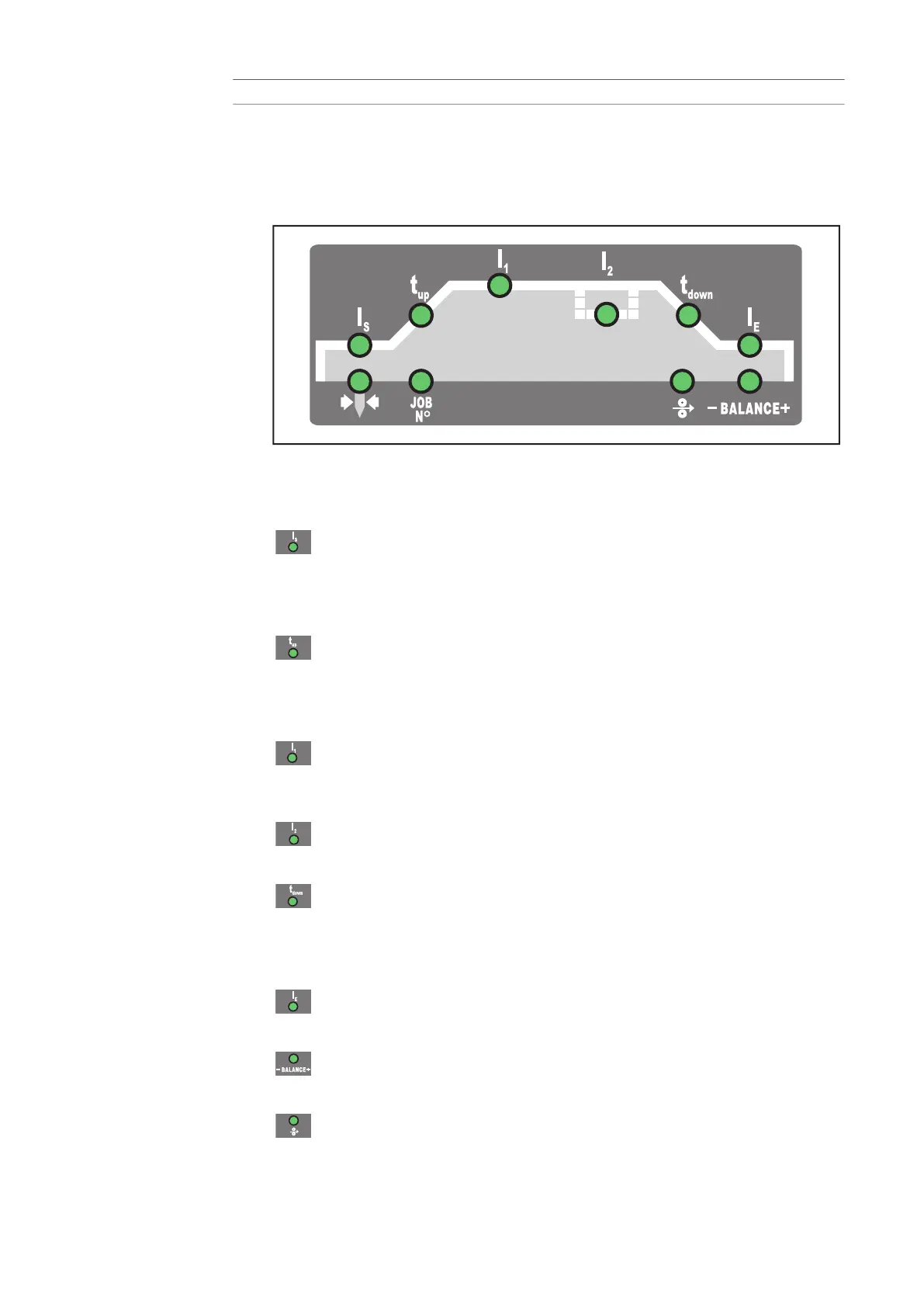

(11) Welding parameters overview

The welding parameters overview contains the most important welding parameters

to be used when welding. The sequence of welding parameters follows a clothes-

line structure. Use the left and right welding parameter selection buttons to navigate

within the welding parameters overview.

Welding parameters overview

The welding parameters overview contains the following welding parameters:

Starting current Is

for TIG welding

The starting current I

S

is saved separately for the "TIG AC welding" and

"TIG DC- welding" modes.

UpSlope t

up

when TIG welding, the period over which the current is increased from the

starting current I

S

to the specified main current I

1

The UpSlope t

up

is saved separately for 2-step and 4-step modes.

Main current I

1

(welding current)

- for TIG welding

- for MMA welding

Reduced current I

2

for TIG 4-step mode and TIG special 4-step mode

DownSlope t

down

when TIG welding, the period over which the current is decreased from the

specified main current I

1

to the final current I

E

The DownSlope t

down

is saved separately for 2-step and 4-step modes.

Final current I

E

for TIG welding

Balance

used to set the fusing power/cleaning action for TIG AC welding

Wire speed (only for MagicWave 4000 / 5000)

for setting the Fd.1 welding parameter if the cold wirefeeder option is avail-

able

No. Function

Loading...

Loading...