GEDA

®

MINI 60 S / MAXI 120 S / MAXI 150 S Maintenance - Checking - Cleaning

BL068 GB Edition 03/2015 63 / 90 Assembly and Operating Manual

8 Maintenance - Checking - Cleaning

The entire manual and operating manual must be read for all mainte-

nance / servicing tasks.

It is not permitted to carry out tasks if the type and scope of the tasks

are unclear, or the resulting hazards and actions to be initiated to

avert hazards are unclear. All unclear issues must be resolved before

starting work. All safety instructions must be complied with.

Workshop equipment that is suitable for the specific work is impera-

tive for carrying out servicing and maintenance tasks. When carrying

out maintenance tasks at greater height, fall protection must be worn!

Keep all handles, railings and the ground free from dirt and contamina-

tion.

8.1 Inspections

Inspections before commissioning, recurring inspections and in-

termediate inspections must be carried out according to national

regulations.

During the checks, the condition, presence and function of all safety-

related features of the machine are checked using appropriate proce-

dures. Appropriate procedures are:

• Visual inspections

• Function and efficacy checks

• Checks using measurement and test equipment

For each test, the scope of the test, type of test and the execution of the

test by competent persons must be defined by the operating company.

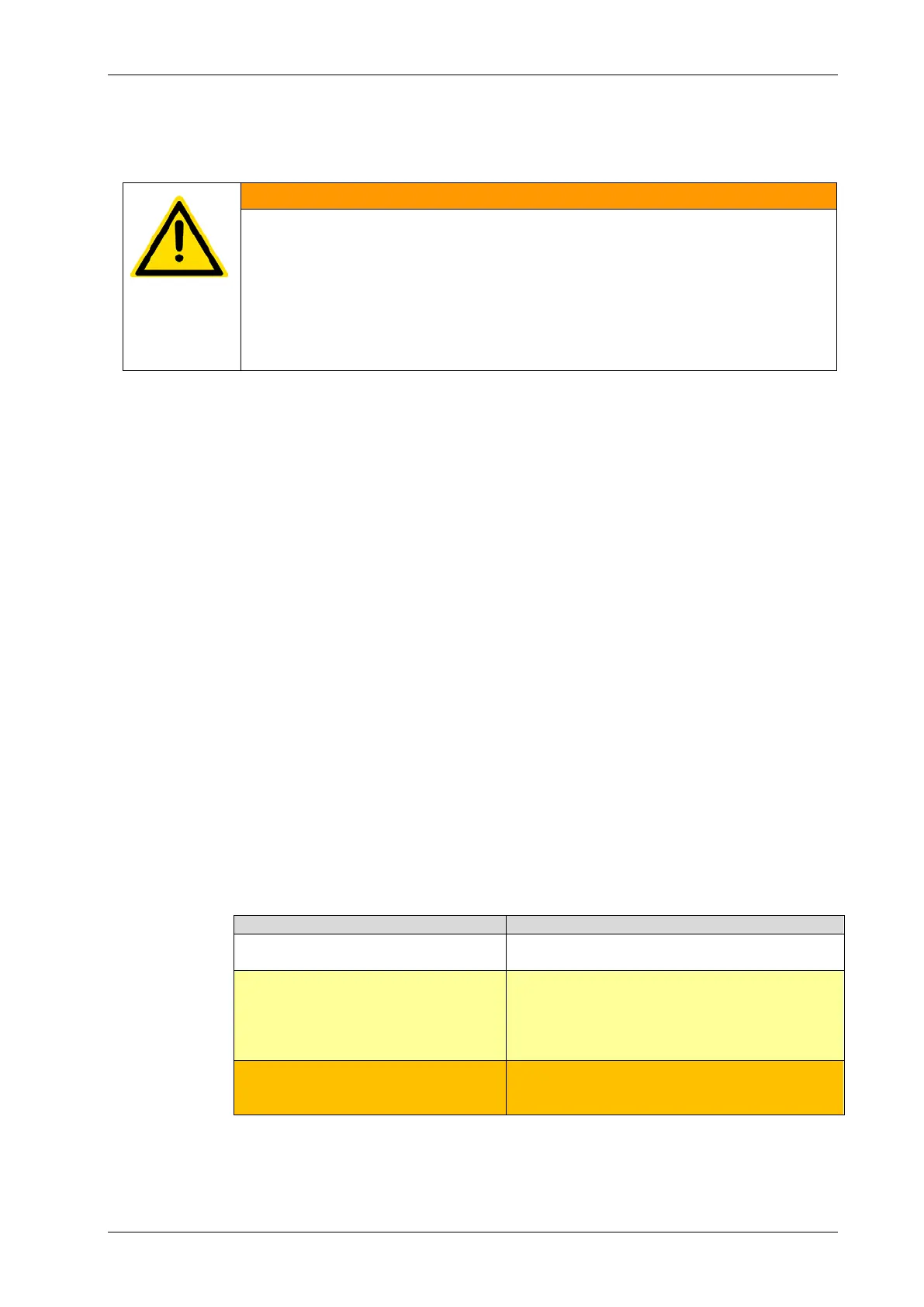

Check by a trained person

Basic visual inspection and function check

with few test steps and simple evaluation

Check by a competent person

Checking due to special events, e.g.

- Assembly

- Maintenance

Checking by an accredited inspec-

tion body (technical specialist)

Checking in accordance with national regula-

tions

Loading...

Loading...