Rev. 00 02/21

16

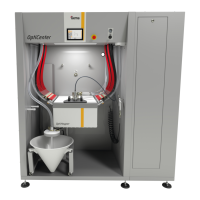

Product description OptiCenter OC09

For a better understanding of the interrelationships in powder coating, it is

recommended that the operating instructions for all other components be

read as well, so as to be familiar with their functions too.

Field of application

The powder management center is suitable for use in plants with a closed

powder circuit:

Conveying

– Precision conveying from the integrated powder container

(OptiHopper) to the applicators

– Recovered powder is returned to the system

Optional:

– Fresh powder directly from the (original) powder bag

– Fresh powder directly from the (original) powder box

– Powder directly from the large-volume powder container (60 or 100

liters)

– Fresh powder from a Gema fresh powder system

– Powder level monitoring by level sensor(s)

Cleaning

– Automatic internal cleaning of suction tubes, powder conveyors,

powder hoses and guns

– Manual cleaning of the OptiHopper is supported with automated

cleaning steps and fixed built-in suction unit

– Supply of the recovered powder

– The working environment remains clean

Controlling

– No own exhaust air system – the powder management center does

not have its own exhaust air system and will be therefore connected

directly to the after filter

Reasonably foreseeable misuse

– Operation without the proper training

– Use of moist powder

– Insufficient fluidization at the suction point

– Use with insufficient compressed air quality

– Input pressure too low

– Use in connection with unauthorized coating devices or components

Loading...

Loading...