Rev. 00 02/21

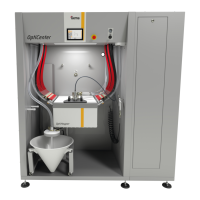

OptiCenter OC09 Fault clearance

81

Fault clearance

Error messages

If faults occur in the powder management center, an error message

shown in red lettering appears on the display.

No release for cleaning, X axes not in cleaning position

Sieve error or switched off

Level sensor detects no powder

The causes of these errors must be eliminated, before further procedures

can be carried out (refer to troubleshooting guide).

If the error has been eliminated, the display returns to the previous menu

again.

Troubleshooting guide

No powder feed from the

OptiHopper

Powder accumulation on

optional level sensor

– Clean the sensor

– Readjust the sensor

sensitivity

– Check the fluidizing of

the sensor if necessary,

increase the fluidizing air

pressure

Optional compressed air pulse

cleaning does not work

Check function at

corresponding output (see also

“Pneumatic diagram”), replace

if necessary

Optional level sensor defective

Loading...

Loading...