Rev. 00 02/21

26

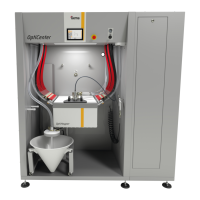

Product description OptiCenter OC09

Fig.

Principle of operation

Powder circuit

During the typical OptiCenter (7) operation, the powder bag is put in the

powder bag cone. The powder is fluidized in the bag with the

fluidizing/suction lance and then fed to the OptiHopper (9). The fluidized

powder is sucked in by the conveyors and fed through the powder hoses

to the guns/spray nozzles (8). The powder, which does not adhere to the

workpieces, will be absorbed by the exhaust air of the booth (1) and

separated from the air in the cyclone separator (2).

The separated powder is cleaned by passing it through the integrated

sieve (3) and fed back into the OptiHopper (9) by the dense phase

conveyor (4), where it is prepared again for coating operation.

fig.

: Powder flow in the plant

1 Booth

2 Cyclone separator

3 Screen

4 Dense phase conveyor

5 After filter

6 Waste container

7 OptiCenter

8 Automatic powder guns

9 OptiHopper

10 Exhaust air ducting

The rest of the non-separated powder (most of it is fine particles) goes

into the after filter (5). The after filter separates the powder into a waste

container (6), which is positioned directly under the filter elements and is

very easy to empty. The cleaned air then exits the filter and is fed directly

back into the workshop environment.

Loading...

Loading...