Rev. 00 02/21

68

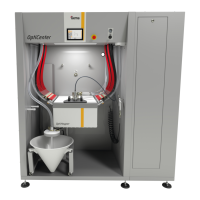

Maintenance / Repairs OptiCenter OC09

OptiCenter maintenance

Maintenance schedule

The following components or modules are subject to a maintenance

schedule:

Pneumatic parts, pinch valves

Check for powder

residues and clean

Fluidizing plate in OptiHopper

Pinch hoses in all pinch valves

NW15

Filter element check valves

injectors

All electrical screw and clamp

connections

The specified intervals are based on operation of 8 hours per day.

The service life of the components depends heavily on the service

duration, the powder quality and the quality of the air supply.

Check for unusual noises

During operation of the machine pay attention to unusual noises. Stop the

machine immediately if an unusual noise can be heard. Check the

components at the noise source.

If no clear cause can be found, contact Gema customer service.

Wearing parts

Wearing parts replaced during maintenance can be individually

purchased (refer to spare parts list).

Loading...

Loading...